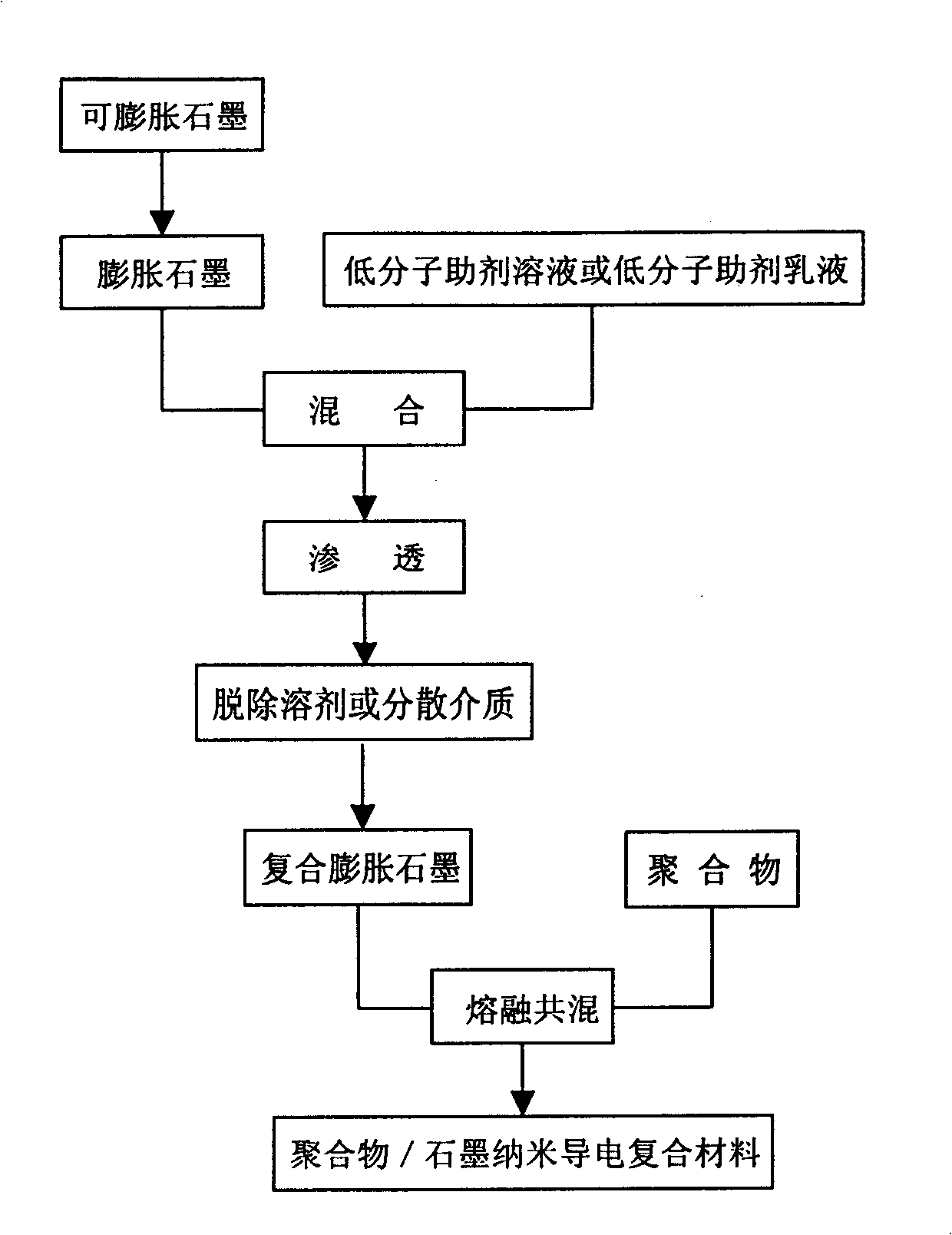

Process for preparing polymer and graphite conductive nano composites

A nano-conductive and composite material technology, which is applied in the field of preparation of polymer/graphite nano-conductive composite materials, can solve the problems of high viscosity, high percolation threshold, poor conductivity, etc., and achieve fast, percolation valve The effect of low value and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Commercially available expandable graphite with an expansion volume of 250 mL / g was placed in a high-temperature furnace at 900° C. for expansion to obtain expanded graphite. According to the ratio of expanded graphite: dibutyl phthalate: absolute ethanol mass ratio of 1: 2: 30, dibutyl phthalate and absolute ethanol are first mixed uniformly to prepare a solution, and then the expanded graphite Suspended and dispersed in an anhydrous ethanol solution of dibutyl phthalate, and placed in an ultrasonic water bath at 60°C for ultrasonic treatment for 4 hours, and then placed in a drum dryer at 80°C, at a drum speed of 50r / min Under the circumstances, the absolute ethanol is removed to obtain the composite expanded graphite of composite dibutyl phthalate.

[0031] According to the ratio of composite expanded graphite: polyvinyl chloride: calcium / zinc composite stabilizer mass ratio of 36:62:2, composite expanded graphite, calcium / zinc composite stabilizer and polyvinyl chlo...

Embodiment 2

[0033] Commercially available expandable graphite with an expansion volume of 300 mL / g was placed in a high-temperature furnace at 700° C. for expansion to obtain expanded graphite. According to the ratio of expanded graphite: dibutyl phthalate: absolute ethanol mass ratio of 1:0.5:24, dibutyl phthalate and absolute ethanol are mixed uniformly to prepare a solution, and then the expanded graphite Suspend and disperse in an absolute ethanol solution of dibutyl phthalate, soak at 50°C for 4 hours, then distill off the absolute ethanol under reduced pressure at 50°C to obtain a composite expanded graphite compounded with dibutyl phthalate.

[0034] According to composite expanded graphite: polyvinyl chloride: calcium / zinc composite stabilizer: phthalate bis (2-ethylhexyl ester) mass ratio is the ratio of 10: 68: 2: 20, composite expanded graphite, calcium / zinc Composite stabilizer, polyvinyl chloride and bis(2-ethylhexyl phthalate) are pre-mixed uniformly in a kneader, and then m...

Embodiment 3

[0036] Commercially available expandable graphite with an expansion volume of 200 mL / g was placed in a high-temperature furnace at 900° C. for expansion to obtain expanded graphite. According to the ratio of expanded graphite: dibutyl phthalate: acetone mass ratio of 1:0.2:20, first mix dibutyl phthalate and acetone evenly to prepare a solution, and add 6% of expanded graphite mass Titanate coupling agent NDZ-201, and then suspend and disperse the expanded graphite in the acetone solution of dibutyl phthalate, soak it at 50°C for 4h, and then distill off the acetone under reduced pressure at 50°C to obtain the composite ortho Composite expanded graphite of dibutyl phthalate.

[0037] According to composite expanded graphite: polyvinyl chloride: calcium / zinc composite stabilizer: phthalate bis(2-ethylhexyl ester) mass ratio is the ratio of 13:65:2:20, composite expanded graphite, calcium / zinc Composite stabilizer, polyvinyl chloride and bis(2-ethylhexyl phthalate) are pre-mixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com