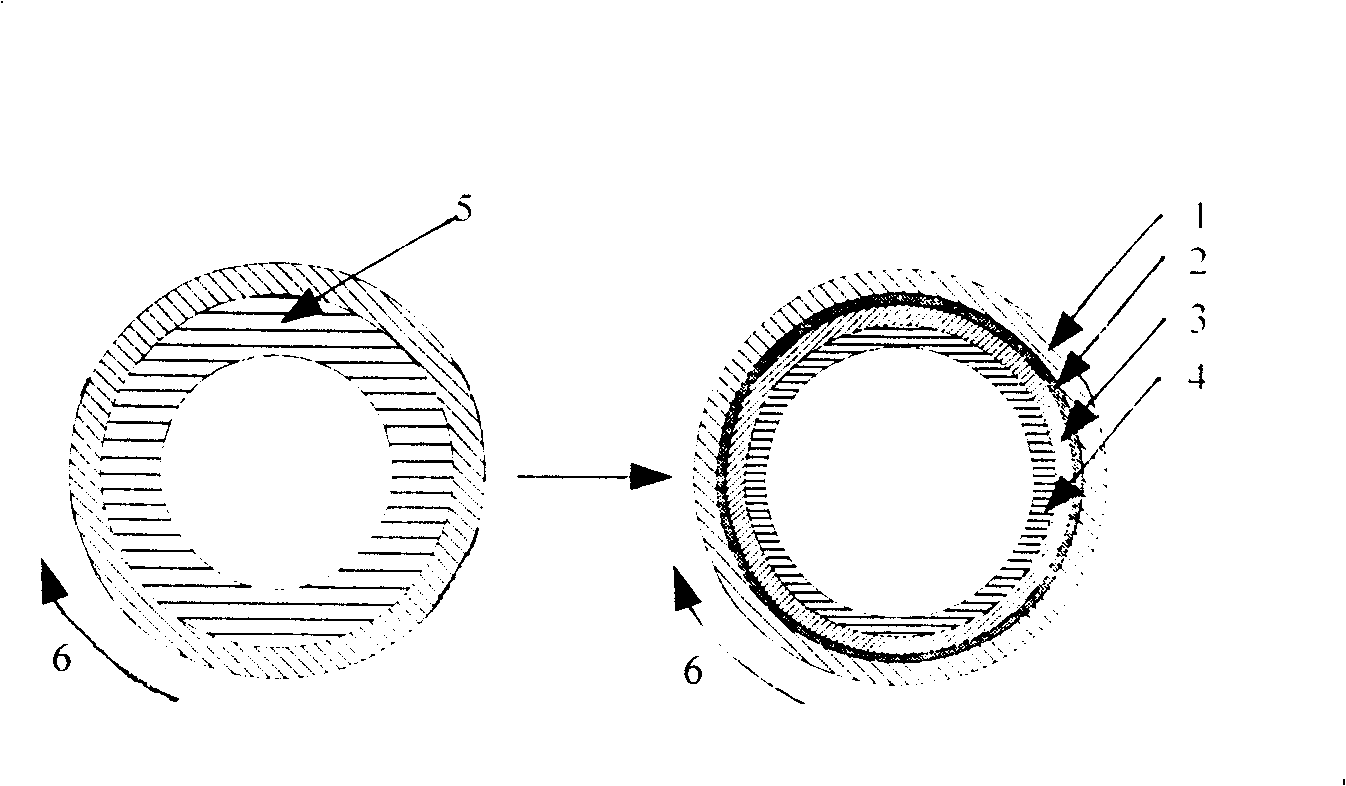

Multi-layered composite tube with ceramic lining and preparation method thereof

A multi-layer ceramic and ceramic lining technology, applied in the field of gradient composite materials, can solve the problems of large differences in physical and chemical properties, affecting the mechanical properties and service life of composite pipes, etc., to improve mechanical properties, reduce thermal stress, The effect of high abrasion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

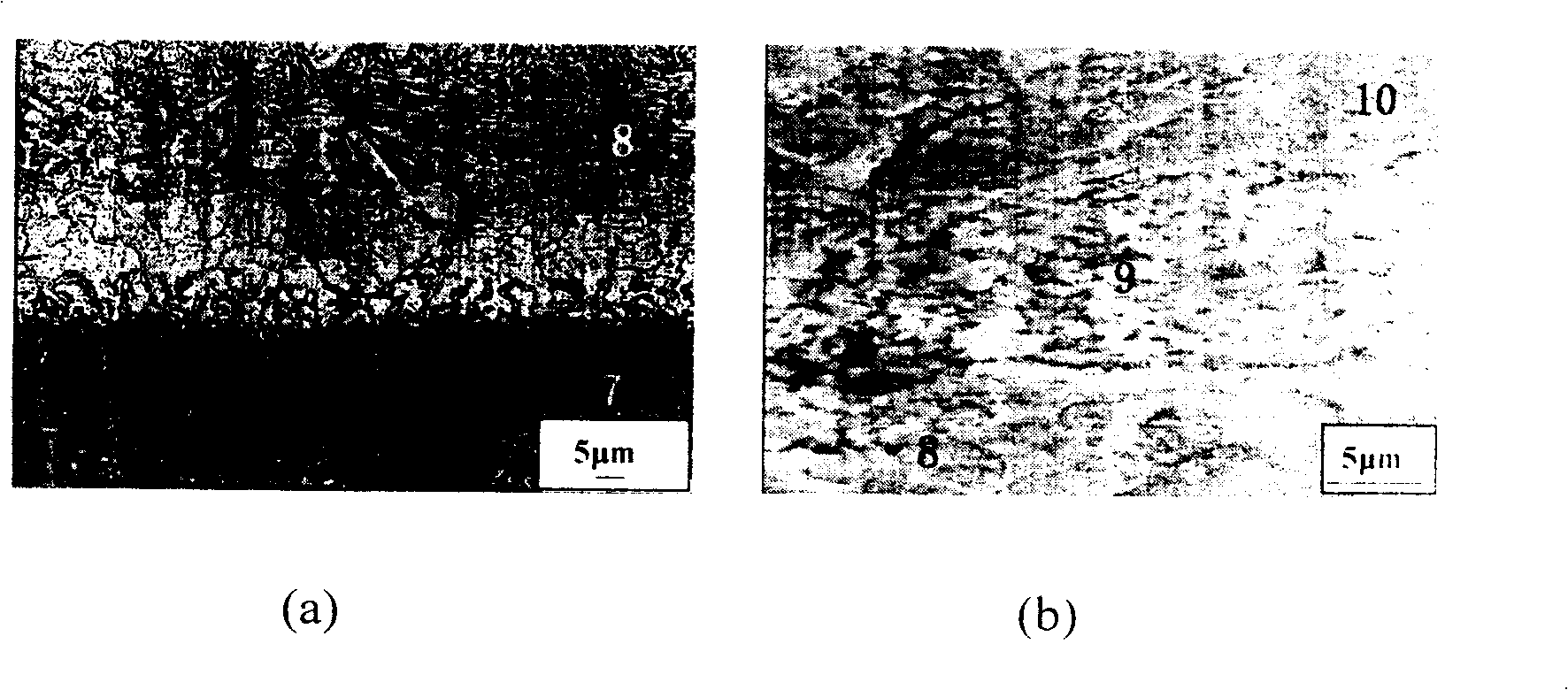

Method used

Image

Examples

Embodiment approach 1

[0023] 20 # Steel pipe, φ52mm, wall thickness 5mm, length 1000mm, containing 313 grams of mixed powder, the proportion of the mixed powder is: aluminum powder 23%, nickel powder 15%, titanium powder 15%, boron carbide 10%, iron oxide 25%, chromium trioxide 5%, sodium borate 7%, powder particle size 15-40μm. When the steel pipe rotation speed reaches 2000 rpm, the powder is ignited with an igniter and the powder forms a self-sustained combustion reaction, and the reaction time is 15 seconds. After the reaction is completed, the cooled composite pipe is subjected to an annealing heat treatment at 350° C.×2 hours. The compressive strength of the composite pipe is 248MPa, and the shear strength of the ceramic lining is 55MPa.

Embodiment approach 2

[0025] Cr-Mo heat-resistant steel pipe, φ85mm, wall thickness 5mm, length 3000mm, containing 2100 grams of mixed powder, the proportion of mixed powder: aluminum powder 25%, nickel powder 10%, titanium powder 10%, boron carbide 5% , Iron trioxide 25%, chromium trioxide 15%, sodium borate 10%, powder particle size is 4-10μm. When the rotating speed of the steel pipe reaches 1700rpm, the powder is ignited with an igniter and the powder forms a self-sustained combustion reaction, the reaction time is 28 seconds. After the reaction is completed, the cooled composite pipe is annealed and heat treated at 300°C for 1 hour. The compressive strength of the composite pipe is 265MPa, and the shear strength of the ceramic lining is 45MPa.

Embodiment approach 3

[0027] 20 # Steel pipe, φ70mm, wall thickness 6.5mm, length 1000mm, 400 grams of mixed powder inside, the proportion of mixed powder is: aluminum powder 22%, nickel powder 15%, titanium powder 10%, boron carbide 10%, two oxides Iron 30%, chromium trioxide 8%, sodium borate 5%, powder particle size is 15-40μm. When the rotation speed of the steel pipe reaches 1500rpm, the powder is ignited with an igniter and the powder forms a self-sustained combustion reaction. The reaction time is 18 seconds. After the reaction is completed, the cooled composite pipe is subjected to an annealing heat treatment at 350° C.×2 hours. The compressive strength of the composite pipe is 265MPa, and the shear strength of the ceramic lining is 40MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| crushing strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com