Variable diameter micro optical fiber ring based optical micromechanical acceleration sensor and its method

An acceleration sensor, micro-fiber technology, applied in the direction of measurement of acceleration, speed/acceleration/impact measurement, instruments, etc., can solve the problems of difficult optical fiber end face coating process, expensive processing and testing instruments, poor parallelism of optical fiber end face, etc. Dynamic measurement range, the effect of improving measurement accuracy and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

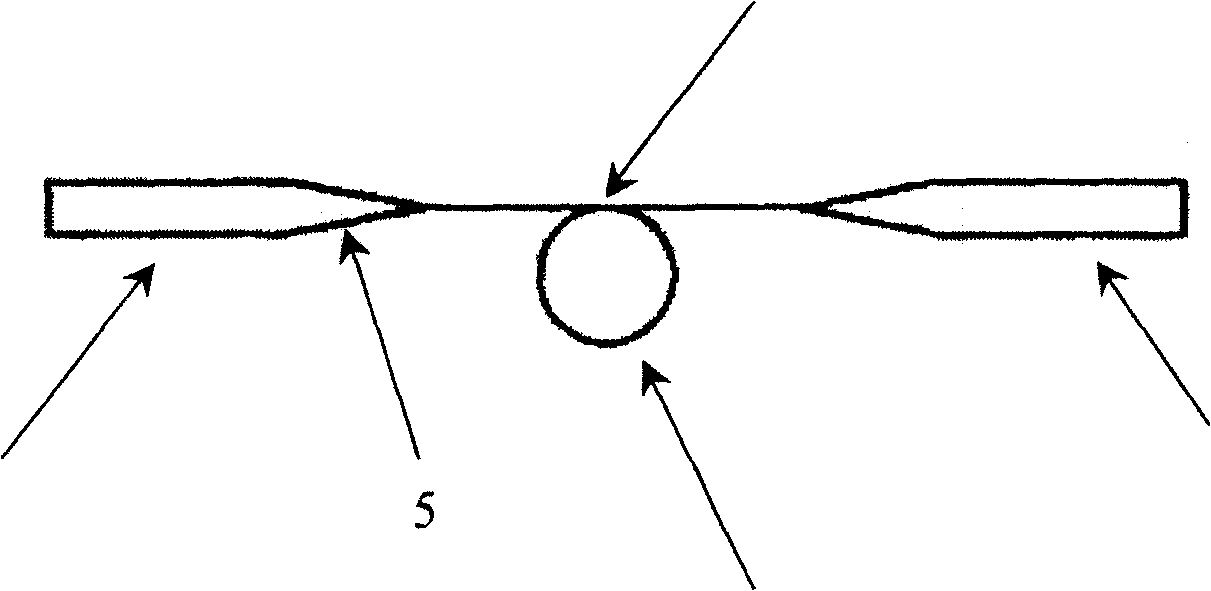

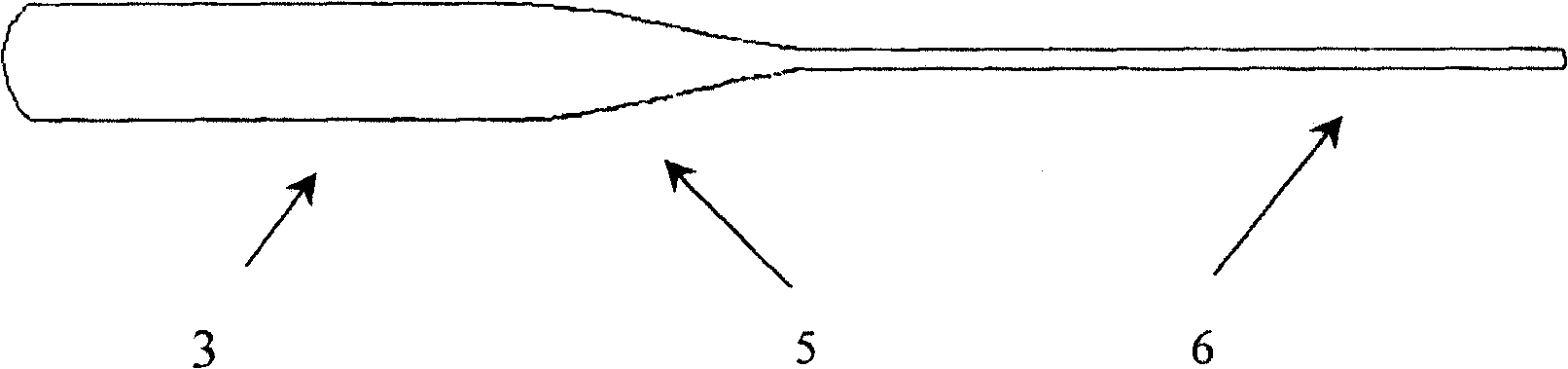

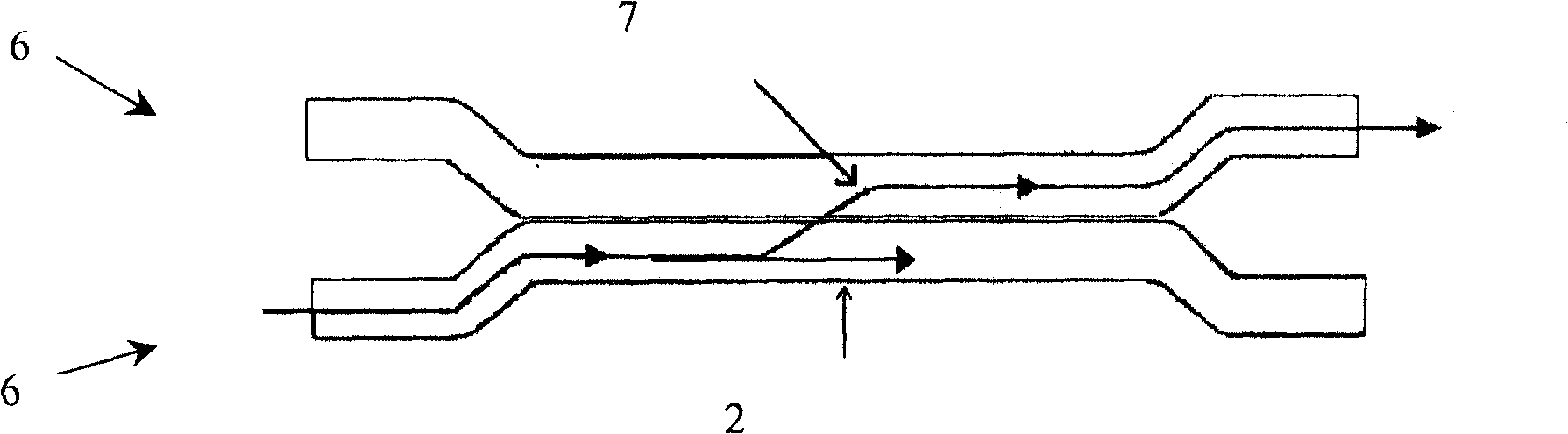

[0034] A standard single-mode optical fiber with a diameter of 125 microns is removed from the coating layer, and the single-mode optical fiber is heated by laser irradiation to draw a micro-fiber with a diameter of 5 microns, which includes a standard optical fiber, a transition zone and a micro-fiber. A movable mass supported by an elastic micro-cantilever beam with a V-shaped groove and a fixed frame connected to it are processed by photolithography and wet etching, and a V-shaped groove and a fixed frame are also carved on the fixed silicon substrate. The structure of the circular groove, and a layer of magnesium fluoride film with a thickness of 0.5 microns is coated on the contact surface of the mass block, the silicon substrate and the micro-fiber, and the fixed frame connecting the movable mass block and the fixed silicon substrate are integrated in the same on the substrate. The two micro-fibers in the coupling area of the micro-fiber ring are axially parallel, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com