Automobile electric booster sterring system and treating method for rotary shaft thereof

A technology of electric power steering and steering shaft, which is applied in the direction of electric steering mechanism, heat treatment furnace, heat treatment equipment, etc. It can solve the problems of unfavorable large-scale installation of low-end vehicles, unfavorable product market competition, and high price of steering mechanism. The effect of material cost, smooth up and down displacement, and improved surface finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

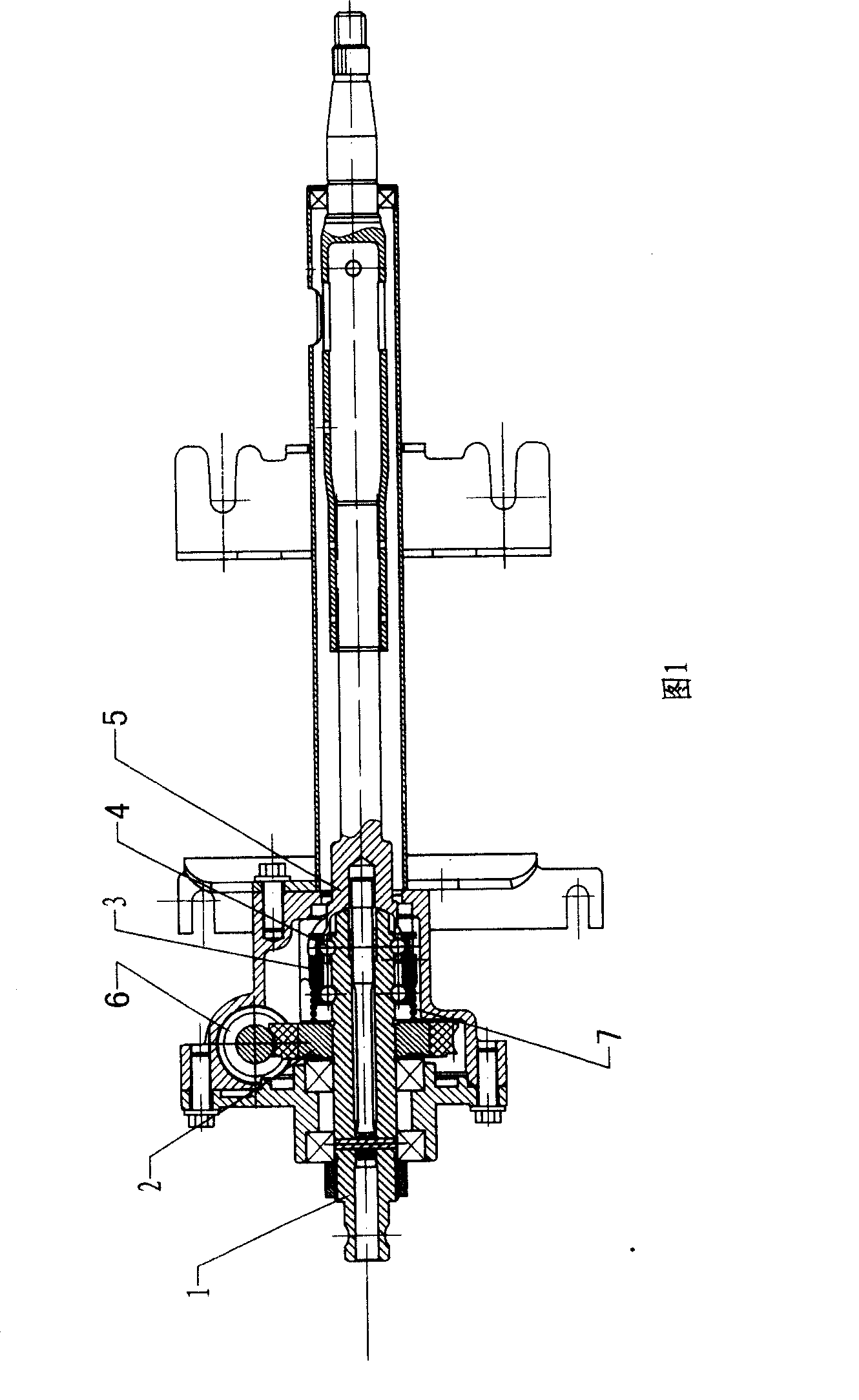

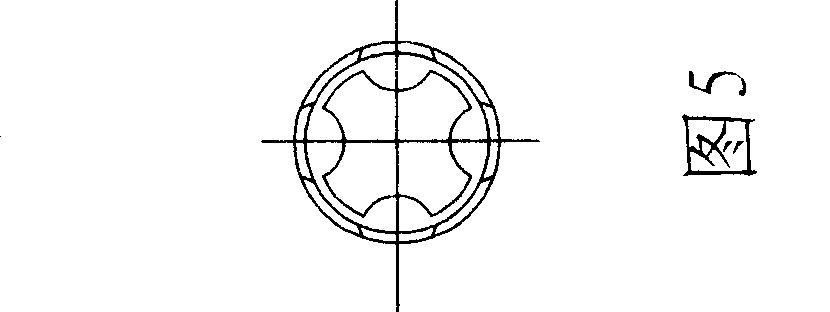

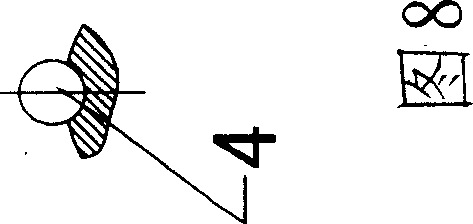

[0027] The automobile electric power steering system of the present invention is mainly composed of a rotating shaft connected by a worm gear shaft 1 and a steering shaft 5, a worm gear 2 arranged on the worm gear shaft, a servo motor 6 engaged with the power output end and the worm gear 2, and a motor for controlling the rotation of the servo motor 6 It consists of a control module, a torque sensor that collects signals for the control module, and a vehicle speed sensor. With reference to Fig. 4, Fig. 5 and Fig. 7, the worm gear shaft 1 and the steering shaft 5 are connected by splines, and the two are in clearance fit. FIG. 1 shows that a worm gear 2 is provided on a worm gear shaft 1 , which meshes with a worm on the output shaft of a servo motor 6 . image 3 It shows that in order to make the gear teeth of the worm wheel 2 easy to process, improve its wear resistance, toughness, tensile strength, and surface finish, and have a long service life and good economy, the worm w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com