Preparation process of metal oxide film

An oxide film and metal technology, applied in the field of materials, can solve the problems of poor mechanical properties of basebands, inability to directly prepare YBCO films, and reduced use value of strips.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

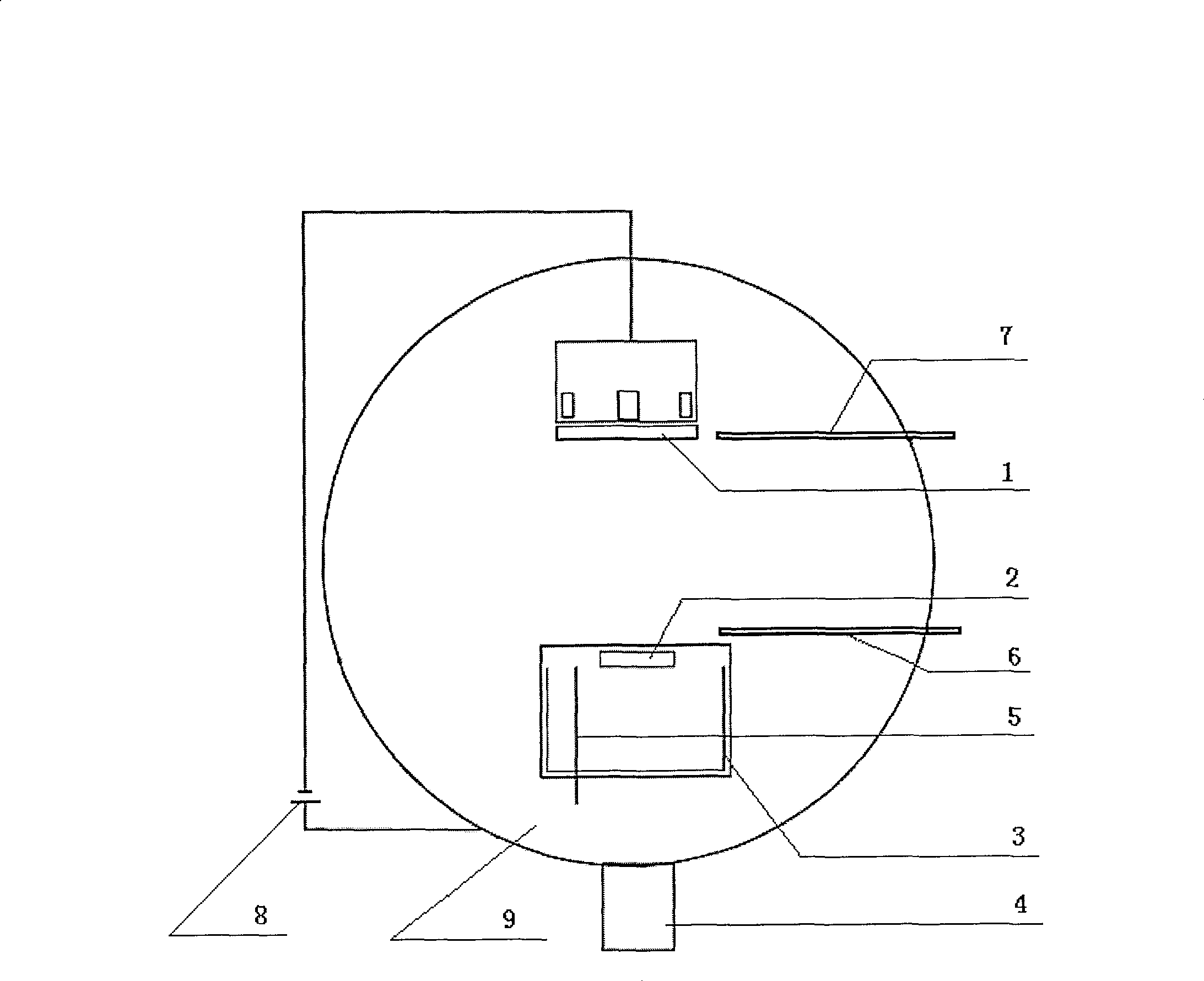

[0034] see figure 1 , the CeO was prepared using the following steps 2 film:

[0035] a. Place the metal cerium target on the target stage 1, place the NiW3% biaxial textured substrate on the substrate stage 2, place the heating resistance wire 3 around and below the substrate stage, and place the thermocouple 5 on the substrate Next to stage 1 , target stage 1 , substrate stage 2 , heating resistance wire 3 and thermocouple 4 are all placed in growth chamber 9 . On the right side of the growth chamber 9, close to the substrate stage, there is an inlet pipe 6 for passing water vapor or oxygen, and on the right side of the growth chamber 9, near the position of the target stage, there is an inlet pipe 7 for passing argon and hydrogen gas, with a lower opening The vacuum pump 4 (mechanical pump and molecular pump) is connected, and the positive and negative electrodes of the sputtering power supply 8 are respectively connected to the outer cavity and the target stage.

[0036...

Embodiment 2

[0048] The difference between this embodiment and embodiment 1 is that

[0049] In step b, maintain a 0.7Pa argon-hydrogen mixed gas in the growth chamber 9;

[0050] In step d, the water vapor pressure is 2.4×10 -3 Pa; keep the total pressure at 0.8Pa, and the substrate temperature at 800°C;

[0051] In step e, the heating time is 30 minutes.

[0052] This specific embodiment is described in detail by taking Ce as an example, and the present invention is also applicable to other rare earth metal thin films.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com