Ceramic metal composite bonding agent used for cube boron nitride grinding wheel

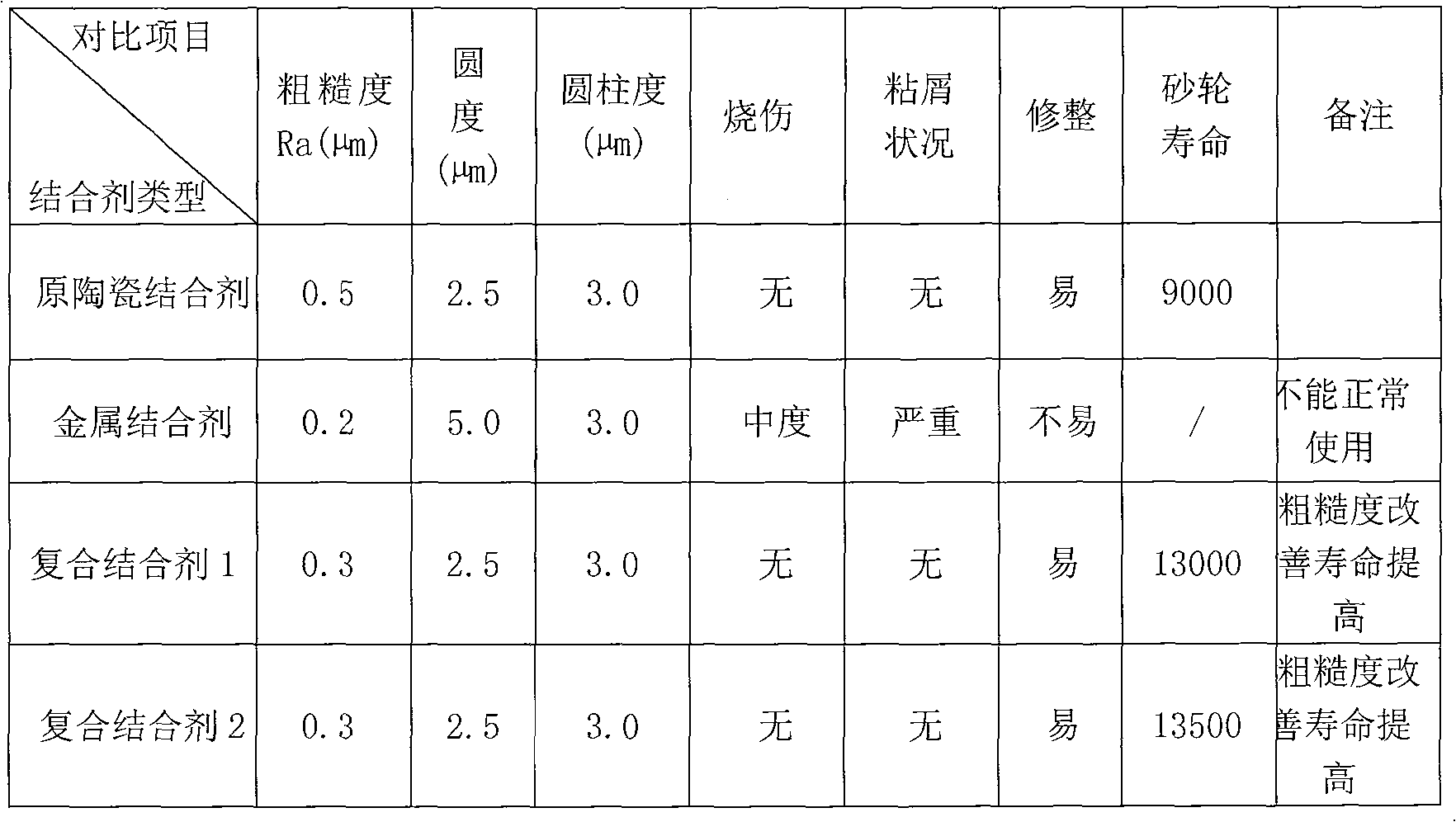

A technology of composite binder and cubic boron nitride, which is applied in the field of binder, can solve the problems of large surface roughness, difficulty in heating and clogging, easy clogging and heating, etc., and achieve good grinding wheel repair performance, improved grinding wheel performance, The effect of improving the life of the grinding wheel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Vitrified metal composite bond for cubic boron nitride grinding wheel, which is composed of the following raw materials in weight percentage: silicon dioxide SiO 2 50%, aluminum oxide Al 2 o 3 25%, potassium oxide K 2 O 7%, sodium oxide Na 2 O6% and barium oxide BaO 8%, copper powder Cu 3%, tin powder Sn 0.7% and zinc powder Zn 0.3%.

Embodiment 2

[0017] Vitrified metal composite bond for cubic boron nitride grinding wheel, which is composed of the following raw materials in weight percentage: silicon dioxide SiO 2 46%, aluminum oxide Al 2 o 3 22%, potassium oxide K 2 O 8.5%, sodium oxide Na 2 6.5% and barium oxide BaO 9%, copper powder Cu 6%, tin powder Sn 1.5% and zinc powder Zn 0.5%.

[0018] The preparation process of the two embodiments is the same:

[0019] Add copper (Cu), tin (Sn) and zinc (Zn) powders (particle size ≤20 μm) that have been thoroughly mixed in advance according to the proportion of the formula to the ceramic powder (particle size ≤ 40 μm) of the original formula, stir evenly, and pass through 60 mesh and 150 mesh sieves Net each time and then back up.

[0020] Make CBN grinding wheel example with composite bond of the present invention

[0021] ①Grinding wheel formula

[0022] CBN abrasive (grain size: 80 / 100): 70%

[0023] Composite binder: 30%

[0024] Wetting agent (20% concentrati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com