Production process for graphitized cathode

A production process and graphitization technology, applied in the field of graphitized cathode production technology, can solve the problems of high resistivity, poor thermal conductivity, high price, etc., and achieve the effect of reducing cathode pressure drop, reducing influence, and slowing down aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

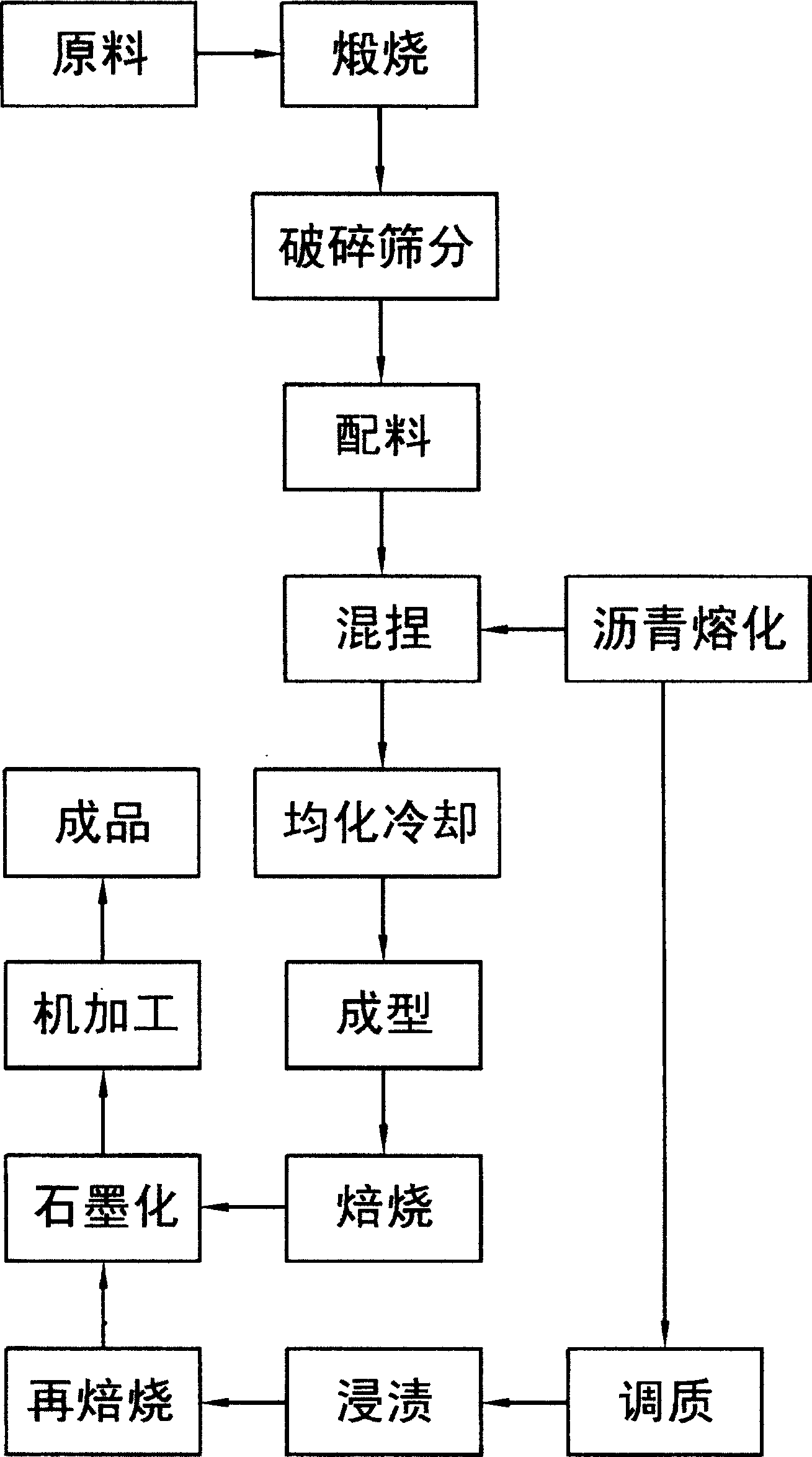

Image

Examples

Embodiment Construction

[0016] Embodiments of the present invention: select easily graphitized delayed petroleum coke and pitch coke to mix, the ratio is: petroleum coke 7: pitch coke 3, utilize tank type calciner to calcinate, through crushing and screening, the raw material of different granularity is in proportion (dry Ratio: 4-2mm 20%, 2-1mm 16%, 1-0.5mm 12%, 0.5-0.25mm 8%, 0.25-0.09mm 22%, 0.09-0mm 22%) after mixing, add 20% (accounting for The hard asphalt binder with a high carbon residue ratio) is kneaded by a kneader, cooled to 140-160°C with a homogenizing cooler, and then entered into a vibration molding machine to be processed into a carbon block blank shape for the cathode required by the electrolytic cell. Carbonize the binder pitch with a ring-type roasting furnace with a cover, vacuumize the opening hole of the carbon block blank with a high-pressure impregnation tank, and then inject asphalt and pressurize it to 1.3-1.5MPa, so that the pitch is immersed in the opening hole of the carb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com