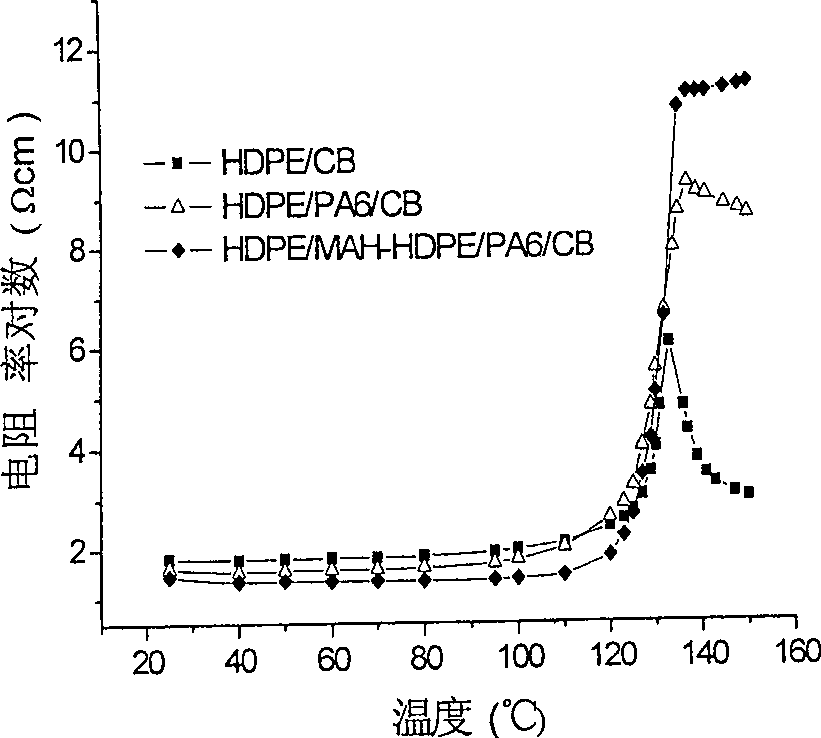

Method for improving high-density polyethylene /carbon ink composite material positive temperature coefficient property

A technology of high-density polyethylene and composite materials, applied in the field of polymer processing, can solve the problems of high cost, high environmental atmosphere requirements, high PTC strength, etc., and achieve the effects of low cost, no pollution to the environment, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

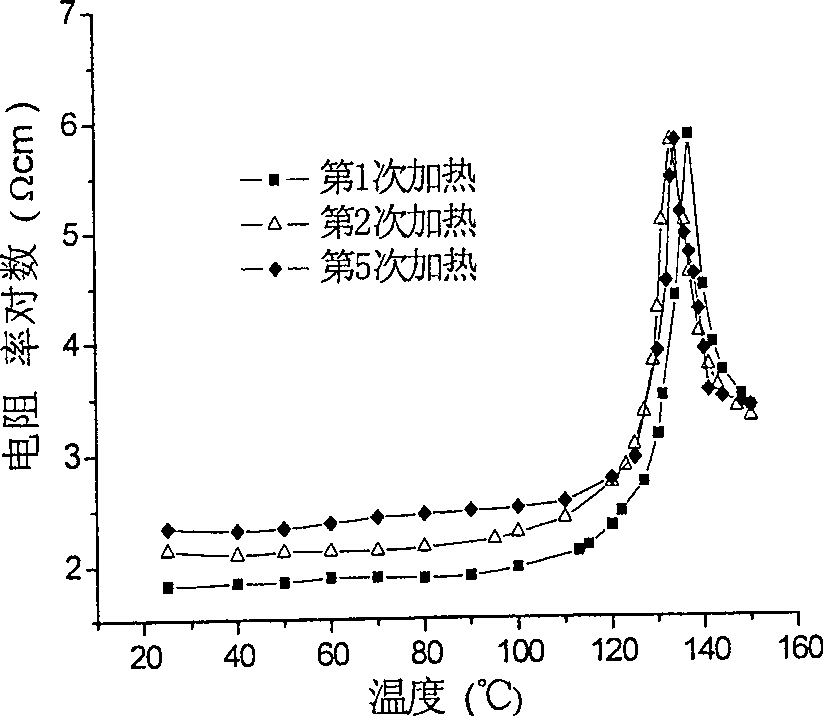

Embodiment 1

[0025] Example 1: Add 100g of high-density polyethylene, 40g of carbon black, 25g of polycaprolactam, 0.3g of antioxidant 1010 and antioxidant 168 to an open mill for mixing at a mixing temperature of 225-235°C. The mixing time was 10 minutes, and the obtained composite was compression molded into a 2mm thick sheet with a plate vulcanizer at a molding temperature of 230-240°C and a molding pressure of 10-15 MPa. Then the surface of the prepared sheet was heated to Press into the copper electrode sheet at 230°C.

Embodiment 2

[0026] Example 2: 100g of high-density polyethylene, 45g of carbon black, 43g of polycaprolactam, 0.8g of antioxidant 1010 and antioxidant 168 were added to an open mill for mixing at a mixing temperature of 225-235°C, The mixing time was 10 minutes, and the obtained composite was compression molded into a 2mm thick sheet with a plate vulcanizer at a molding temperature of 230-240°C and a molding pressure of 10-15 MPa. Then the surface of the prepared sheet was heated to Press into the copper electrode sheet at 230°C.

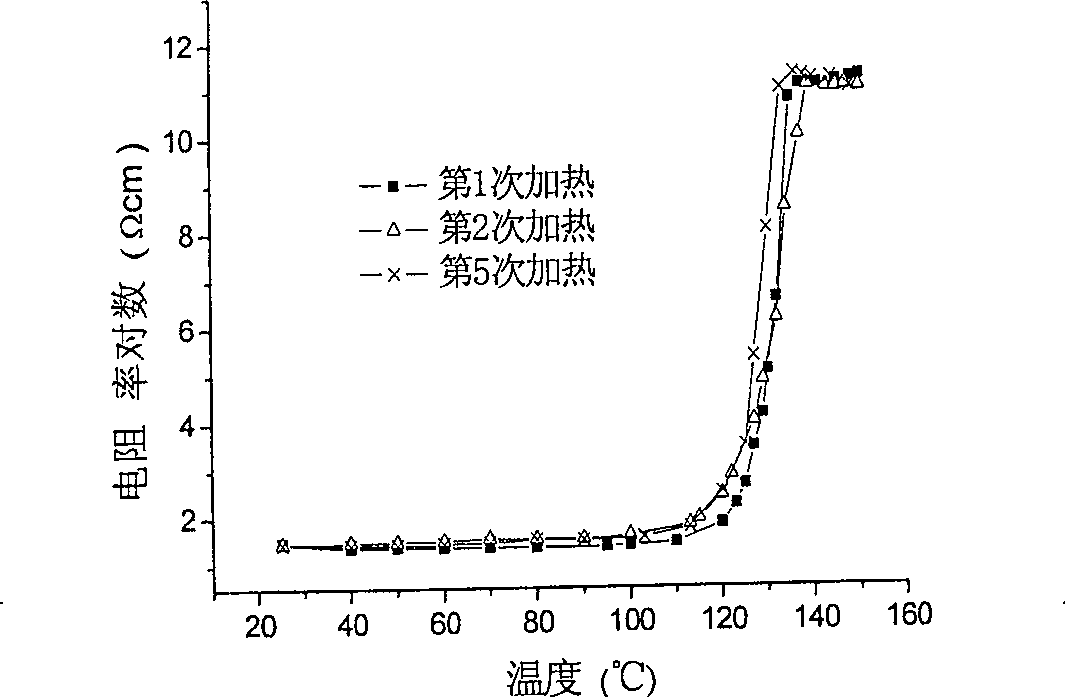

Embodiment 3

[0027] Example 3: Add 100g of high-density polyethylene, 65g of carbon black, 53g of polycaprolactam, 25g of maleic anhydride grafted polyethylene, 0.2g of antioxidant 1010 and antioxidant 168 to an open mill for mixing , The mixing temperature is 235-245℃, and the mixing time is 10min. The obtained composite was compression molded into a 2mm thick sheet with a plate vulcanizer, the molding temperature was 230-240℃, and the molding pressure was 10-15MPa. Then the surface of the prepared sheet was heated to 230℃ and pressed into copper. Electrode sheet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com