Method for removing hydrogen sulfide and hydrogen cyanide from calcium carbide furnace gas

A calcium carbide furnace gas, sodium cyanide technology, applied in separation methods, chemical instruments and methods, hydrogen cyanide preparation/purification/separation, etc., can solve the problem that sodium cyanide and sodium sulfide solutions cannot be directly discharged and the processing cost is high problems, to achieve the effect of improving resource utilization, increasing economic benefits, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

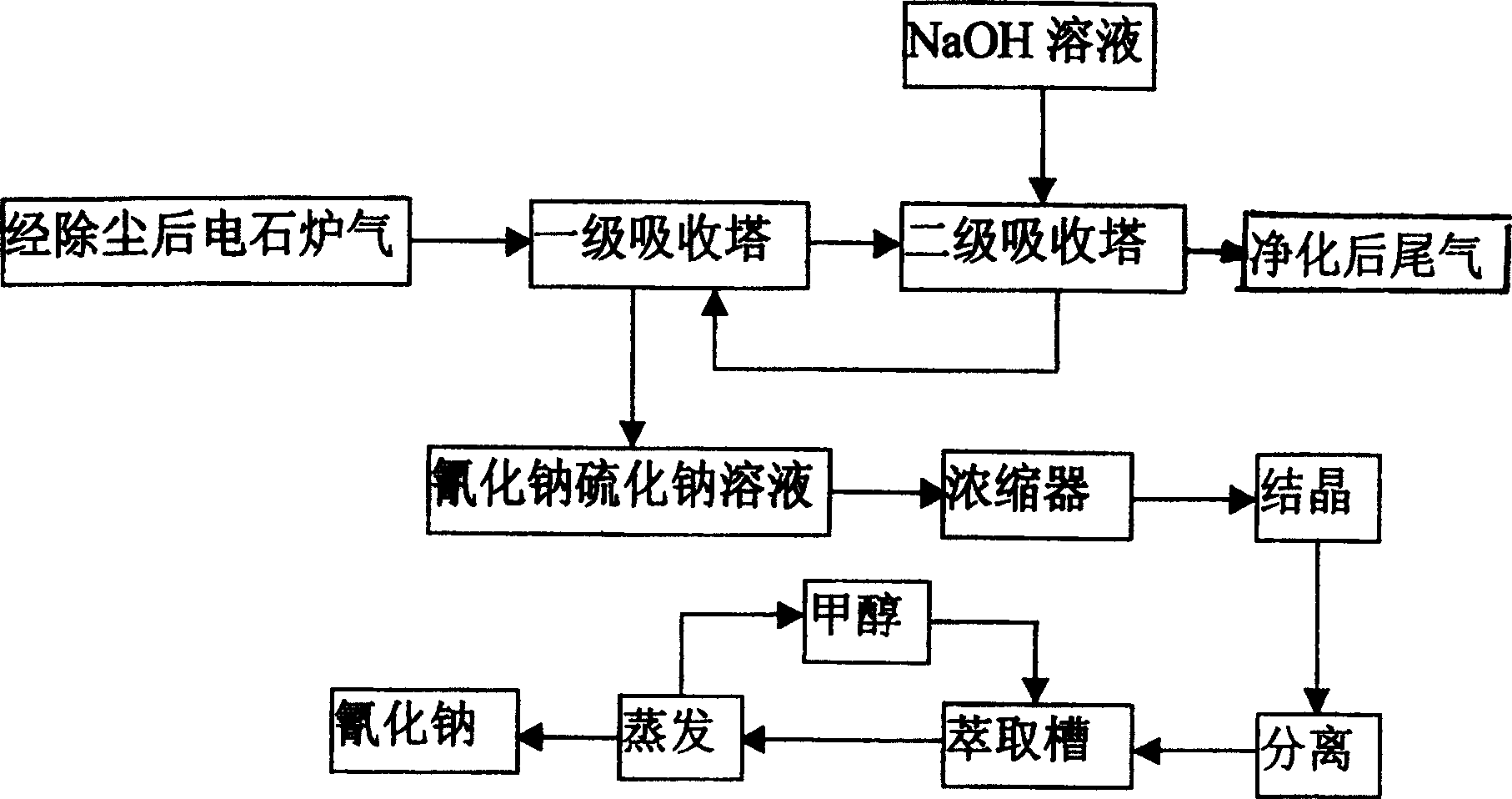

Method used

Image

Examples

Embodiment 1

[0024] Example 1: Calcium carbide furnace gas after dedusting, main chemical components volume %: CO=82, H 2 = 7, CO 2 = 2, O 2 = 2,N 2 =6, HCN=3000mg / Nm 3 , H 2 S=900mg / Nm 3 , at 5000m 3 / h speed passes through two series-connected absorption towers equipped with polypropylene fillers, and is connected with a 180-200m from top to bottom 3 The 18% NaOH solution sprayed at the speed of / h is in reverse contact, the lye enters from the second tower and exits from the first tower, and the mixed solution containing sodium sulfide and sodium cyanide at 20-22% and the purified tail gas can be obtained. Detect HCN in exhaust gas≤50mg / Nm 3 , H 2 S≤50mg / Nm 3 , to meet the requirements of carbon-chemical raw material gas; then the mixed solution is concentrated in a WZI I500 double-effect concentrator at 80-90°C for 25-30 minutes to obtain a mixed solution with a sodium sulfide and sodium cyanide content of 65-70%, Place in a vacuum concentration crystallizer at room temperatu...

Embodiment 2

[0025] Example 2: Calcium carbide furnace gas after dedusting, main chemical components wt%: CO=82, H 2 = 8, CO 2 = 1, O 2 = 2,N 2 =6, HCN=2000mg / Nm 3 , H 2 S=600mg / Nm 3 , at 2000~4000m 3 The speed of / h passes through two series-connected absorption towers equipped with polypropylene packing, and the distance from top to bottom is 150-180m 3 The 16% NaOH solution sprayed at the speed of / h is in reverse contact, the lye enters from the second tower and exits from the first tower, and the mixed solution containing sodium sulfide and sodium cyanide at 20wt% and the purified tail gas can be obtained, and the HCN in the tail gas is detected≤ 50mg / Nm 3 , H 2 S≤50mg / Nm 3 , to meet the requirements of carbon-chemical raw material gas; then the mixed solution is concentrated in WZI I500 double-effect concentrator at 90°C for 25 minutes, at this time, the content of sodium sulfide and sodium cyanide in the mixed solution reaches 66%, and it is placed in a vacuum concentration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com