Absorble magnesium alloy stent possessing double controlledly released coating layer and its preparation method

A magnesium alloy stent, magnesium alloy technology, applied in stents, coatings, medical science and other directions, can solve the problems of fast degradation speed, no drug-loaded coating, etc., and achieve the effect of preventing the coating from falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

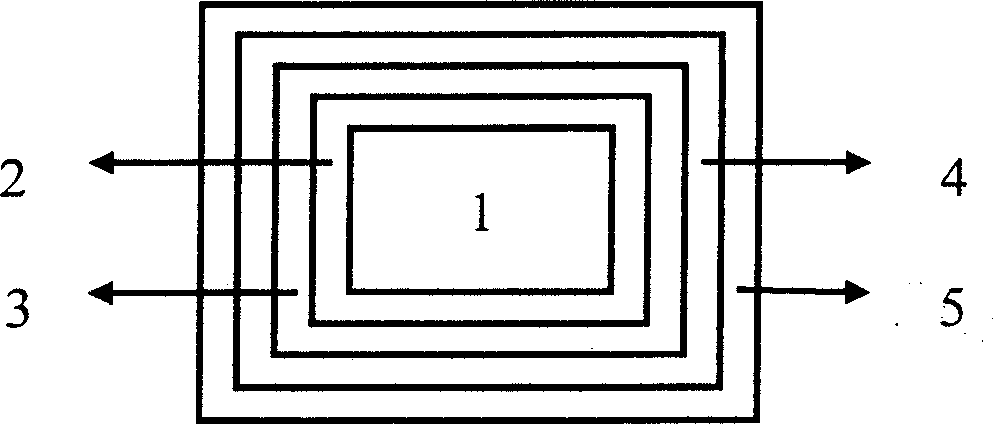

Image

Examples

Embodiment 1

[0018] Magnesium alloy WE43 was engraved into a stent with a laser, and then placed in a 2 Ultrasonic treatment in the pickling solution for 30 minutes, then put it in a vacuum furnace for annealing treatment, raise the temperature to 1100°C at a rate of 3°C / min, keep it for 30 minutes, and then lower it to 20°C at a rate of 4°C / min °C, then use an ultrasonic cleaner with a power of 500W to ultrasonically clean in deionized water for 15 minutes and then dry.

[0019] An anti-corrosion coating is prepared on the dried scaffold base. The method of micro-arc oxidation is adopted, and the electrolyte composition is NaOH20g / L, NaAlO 2 15g / L, H 2 o 2 5g / L. The oxidation time is 40 minutes, and the current density is 0.20A / cm 2 . Afterwards, the stent with the anticorrosion coating was placed in deionized water for ultrasonic cleaning for 30 minutes, and dried at room temperature to obtain the stent with the anticorrosion coating of aluminum.

[0020] Dissolve 1g of chitosan i...

Embodiment 2

[0025] The experimental conditions and operation process of Example 2 are the same as those of Example 1, except for a change: in the process of preparing the cross-linked dense drug-loaded coating, chitosan is changed to collagen.

[0026] The prepared scaffold was tested in artificial simulated body fluid at 37° C., and the result showed that the release percentage of rapamycin was 51.5% in 20 days, and the release period could reach 50 days. The polymer coating degrades within 180-190 days, and the metal stent degrades within 340-350 days.

Embodiment 3

[0028] The experimental conditions and operation process of Example 3 are the same as those of Example 1, except that in the process of preparing the non-crosslinked drug-loaded coating, poly-L-lactic acid was changed to polyglycolic acid.

[0029] The prepared scaffold was tested in artificial simulated body fluid at 37° C., and the results showed that the release percentage of rapamycin was 45.5% at 20 days, and the release period could reach 55 days. The polymer coating degraded within 185-190 days, and the metal stent degraded within 340-350 days.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com