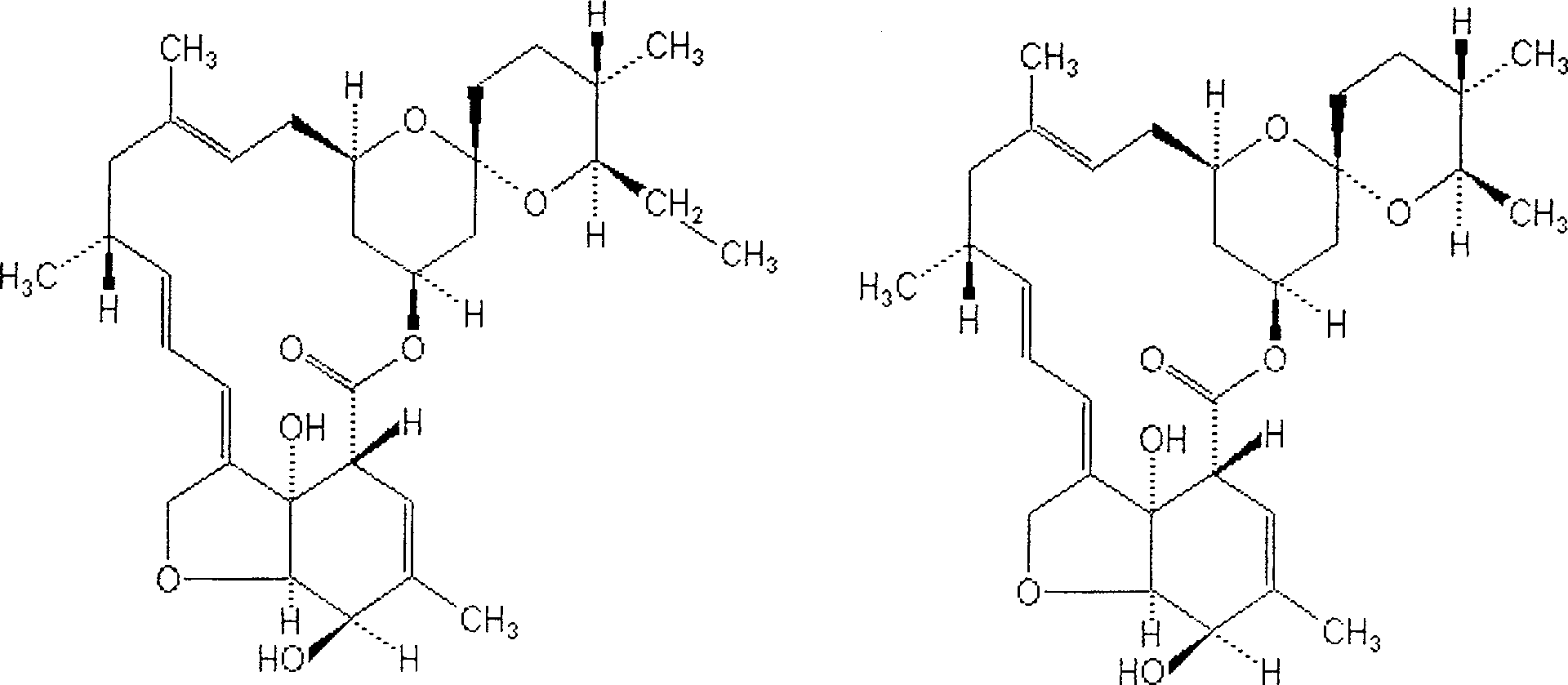

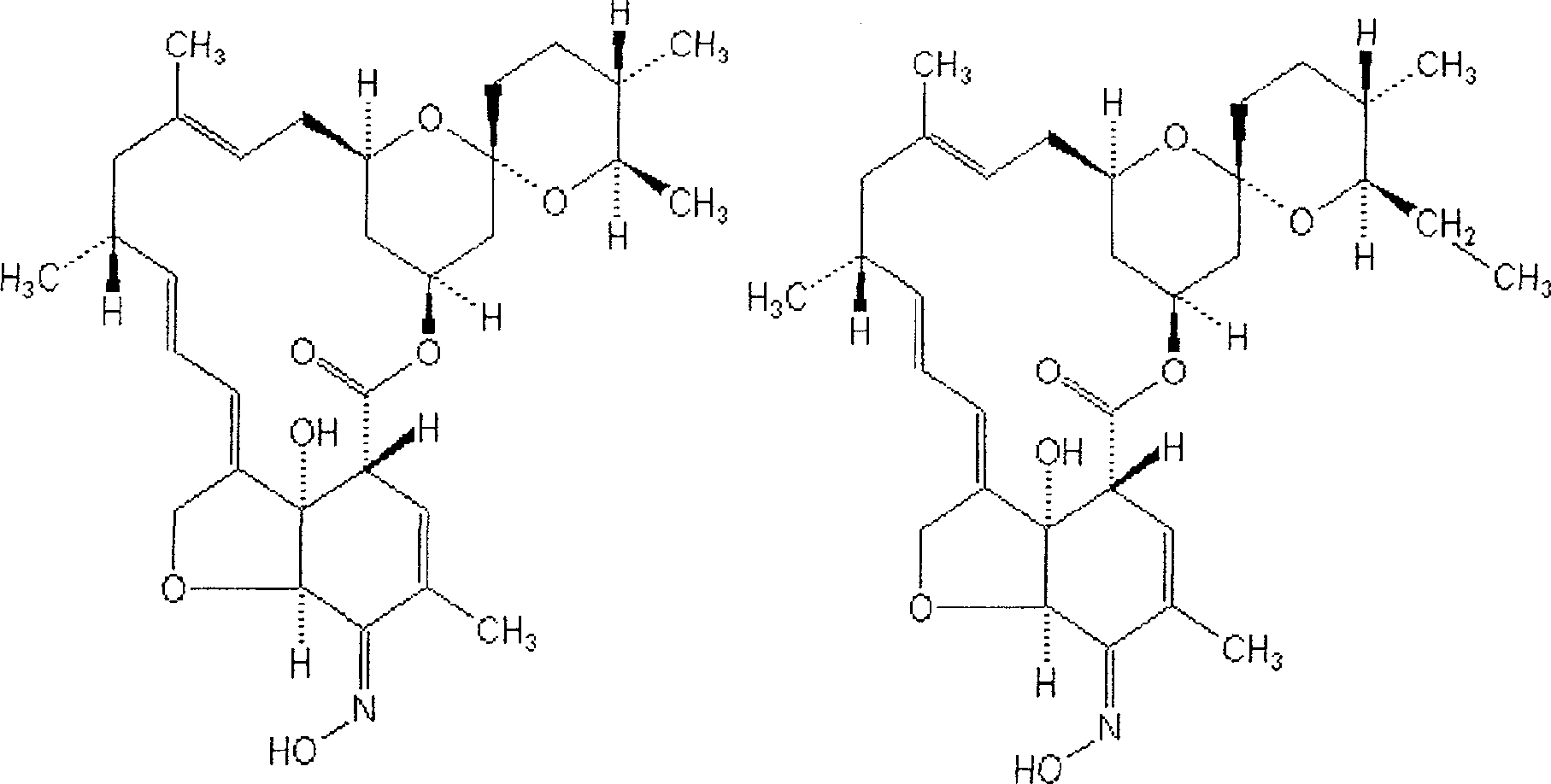

Production of milbemycin and milbeoxime microemusifier, water emusifier and suspending agent

A technology of mirbemycin and mirbeoxime, which is applied in the field of preparation of mirbemycin and mirbeoxime insecticidal microemulsion, water emulsion and suspension agent, can solve problems such as breaking the boundary of physical property requirements of active substances and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1 1.0% milbemycin and milbemycin microemulsion:

[0040] Get milbemycin or milbemycin 2g (the average active ingredient of milbemycin or milbemycin is 50%), dissolve with 7g xylene and 7g ethyl acetate, then add benzylphenol polyoxyethylene polyoxypropylene Base ether, calcium dodecylbenzenesulfonate mixed emulsifier 18g, azone 1g, ethylene glycol 1g, add 1g sodium lauryl sulfate, heat to 40-50°C and stir to dissolve, then add measured 60g water into it , vigorously stirred evenly, maintained for 15-20 minutes, and then returned to room temperature to obtain 100g of 1.0% milbemycin and milbemycin microemulsion.

Embodiment 2

[0041] Embodiment 2 10% milbemycin and milbemycin aqueous emulsion:

[0042] Recipe: milbemycin or milbemycin 20g (the average active ingredient of milbemycin or milbexime is 50%), 17g ethyl acetate, 23 acetone, phenethylphenol polyoxyethylene ether formaldehyde condensate and benzyl Phenolic polyoxyethylene polyoxypropylene ether mixed emulsifier 11g, polyvinyl alcohol 1g, propylene glycol 1g, defoamer 1g, water 26g.

[0043] preparation steps

[0044] 1. Put 17g of ethyl acetate and 23g of acetone into the reactor and mix evenly, add 20g of milbemycin, and keep stirring until the milbemycin or milbemycin is completely dissolved in it, and make an oil for later use.

[0045] 2. Put 26g of water into the reactor, then add benzylphenol polyoxyethylene polyoxypropylene ether and styrene ethylphenol polyoxyethylene ether formaldehyde condensate mixed emulsifier, polyvinyl alcohol, propylene glycol, defoamer Stir continuously until the substances are completely dissolved to form...

Embodiment 3

[0047] Example 3 5.0% milbemycin and milbemycin suspension concentrate:

[0048] Grind 10g of milbemycin or milbemycin (the average active ingredient of milbemycin or milbemycin is 50%) to below 300 microns, mix with 3g of alkyl polyoxyethylene ether formaldehyde condensate and 4g of Tween-80 , use a colloid mill to homogenize and grind the solid particles to about 40 microns, add 5 g of water, further pulverize and homogenize with a high-speed shear emulsifier, and then grind to a solid particle of 0.5-2 microns by a sand mill, take out the ground material, and add two 1.0 g of sodium butylnaphthalene sulfonate and 8 g of ethylene glycol were homogenized with a high-speed shear emulsifier, and 0.3% xanthan gum solution was added to 100 ml during homogenization, and homogenized for 50 minutes to obtain a suspension.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com