Method of assembling quantum dot in mesoporous silica dioxide

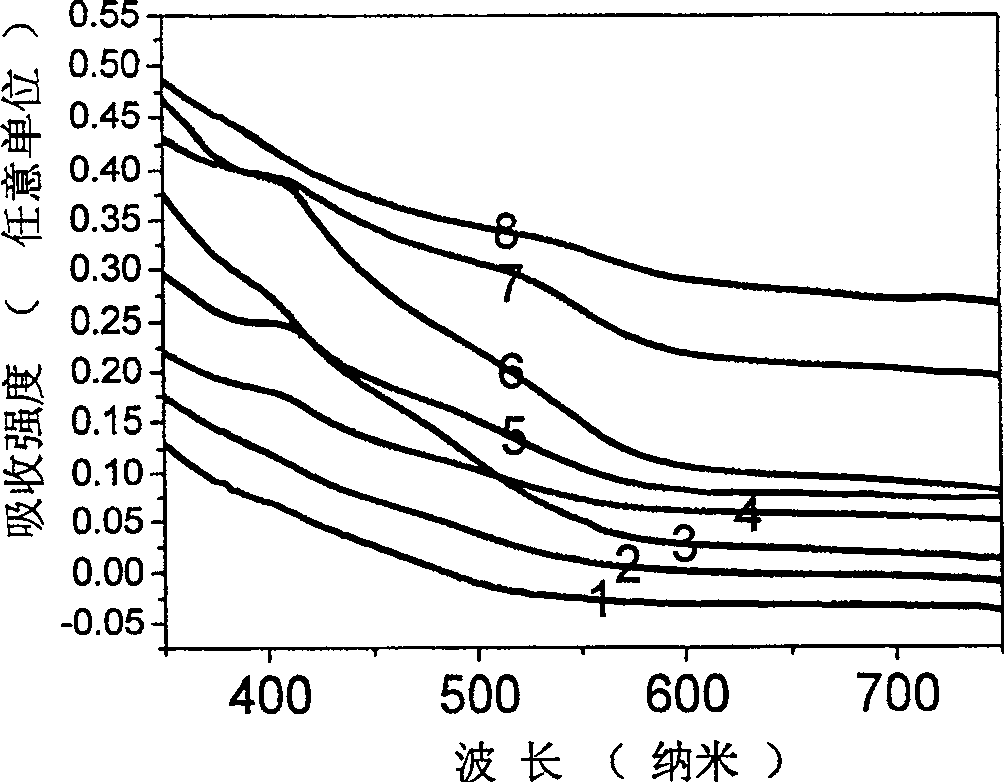

A technology of mesoporous silica and quantum dots, applied in chemical instruments and methods, luminescent materials, etc., can solve the problem that the particle size of cadmium selenide quantum dots is not easy to control, etc., and achieve high yield, simple equipment, and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

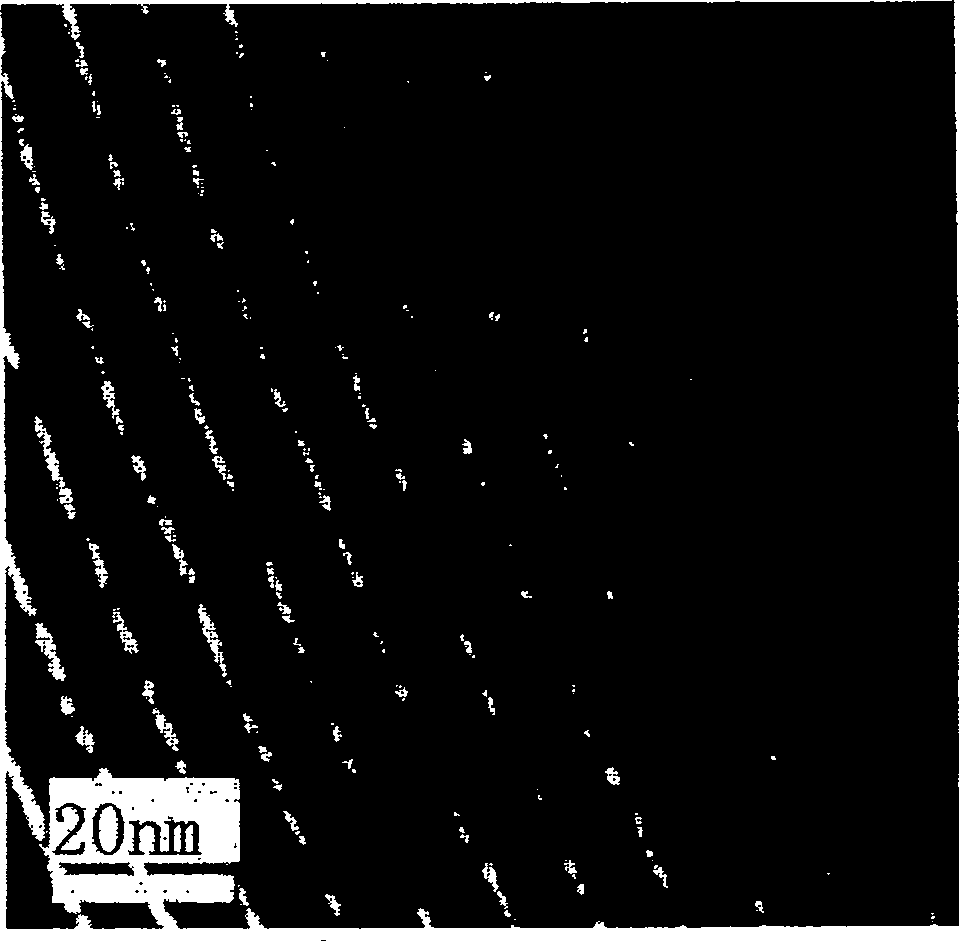

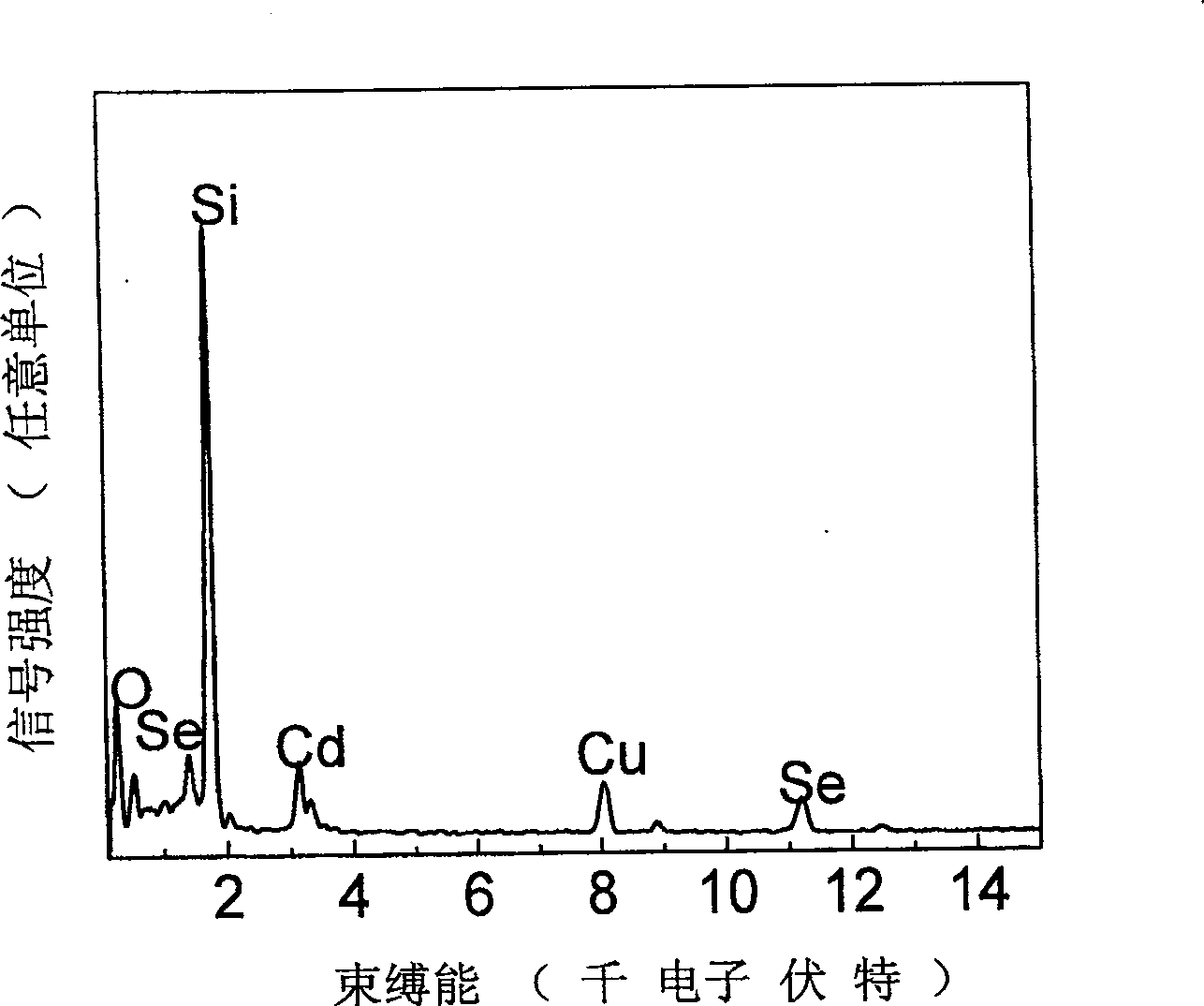

Examples

Embodiment 1

[0028] A. Weigh 1.0 g of SBA-15 and place it in a flask, add 10 ml of aminopropyltrimethoxysilane and 100 ml of anhydrous toluene at room temperature and nitrogen atmosphere, mix and react, and let stand for 48 hours to obtain SBA -15-NH 2 precursor solution.

[0029] B. Weigh 0.2g of precursor SBA-15-NH 2 solution, add 50 ml of ethanol and 0.01 mol of cadmium acetate, stir vigorously, use the amino groups in the pores of mesoporous silica to complex Cd 2+ , generating SBA-15-Cd 2+ precursor solution.

[0030] C. Weigh 0.2g of SBA-15-Cd 2+ The precursor solution, 2g of trioctylphosphine oxide (TOPO), was placed in a three-necked flask and heated to 220°C.

[0031] D. At the same time, weigh 0.15g of Se powder in a pear-shaped bottle, operate in a glove box, add 2ml of tributylphosphine to generate TBP-Se 2- precursor solution.

[0032] E. Use a syringe to inject TBP-Se 2- Quickly inject into the solution synthesized in step C, and stir at the same time. After the injec...

Embodiment 2

[0037] A. Weigh 1.0 g of SBA-15 in a flask, add 10 ml of aminopropyltrimethoxysilane and 100 ml of anhydrous toluene at room temperature and nitrogen atmosphere, mix and react, and let stand for 48 hours to obtain the precursor SBA -15-NH 2 solution.

[0038] B. Weigh 0.2g of precursor SBA-15-NH 2 , add 50 ml of ethanol and 0.01 mol of cadmium acetate, stir vigorously, use the amino groups in the pores of mesoporous silica to complex Cd 2+ , generating SBA-15-Cd 2+ precursor solution.

[0039] C. Weigh 0.2g of SBA-15-Cd 2+ The precursor solution, 2g of trioctylphosphine oxide (TOPO), was placed in a three-necked flask and heated to 250°C.

[0040] D. At the same time, weigh 0.02g of tellurium powder in a pear-shaped bottle, operate in a glove box, add 4ml of tributylphosphine to generate TBP-Te 2- precursor solution.

[0041] E. Use a syringe to inject TBP-Te 2- Quickly pour into the solution from step C while stirring. After the injection, start timing with a stopwatch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com