Preparation method of low-dielectric polyimide fibers

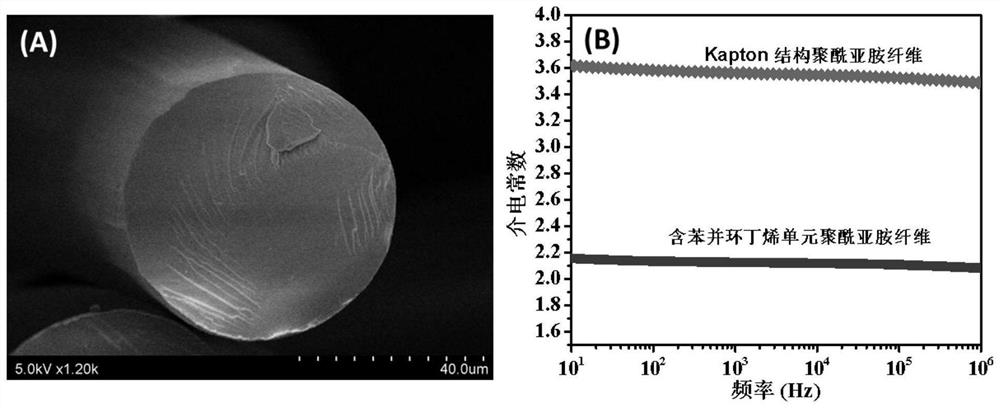

A technology of polyimide fiber and nascent fiber, applied in the direction of fiber chemical characteristics, drawing spinning, single-component synthetic polymer rayon, etc., can solve problems such as unfavorable high-performance low-dielectric composite materials, and achieve expansion Application range, low dielectric constant, dimensionally stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] (1) Under nitrogen protection, in a three-necked flask, add 250 mL of NMP, 11.34 g (0.05 mol) of 2-(4-aminophenyl)-5-aminobenzimidazole (BIA), 4.42 g (0.017 mol) of 3,5-diaminobenzoyl-4-amine-benzocyclobutene (synthesis method such as U.S.Patent 6,534,250[P].2003-3-18.), after stirring for 1h, add 21.74g ( 0.067mol) of 3,3',4,4'-benzophenonetetraacid dianhydride, stirred and reacted at 15°C for 10h; then raised the temperature to 130°C, 145°C, and 155°C for 1h each, and finally raised the temperature to 190°C React at constant temperature for 12 hours to obtain a high-viscosity polyimide solution with a solid content of 13%.

[0041] (2) Take the polyimide solution prepared in step (1) as the spinning solution, let it stand for defoaming, and use solidification as the volume ratio of 1:1 NMP and deionized water as the coagulation bath, and deionized water as the water system bath, using wet spinning technology to prepare polyimide as-spun fibers, dried and set aside. ...

Embodiment 2

[0044](1) Under nitrogen protection, in a three-necked flask, successively add 300 mL of DMAc, 13.04 g (0.058 mol) of 2-(4-aminophenyl)-5-aminobenzoxazole (BOA), 3.66 g ( 0.014mol) of 3,5-diaminobenzoyl-4-amine-benzocyclobutene (synthesis method such as U.S. Patent 6,534,250[P].2003-3-18.), after stirring for 1h, add 32.14g (0.072 mol) of hexafluorodianhydride (6-FDA), stirred and reacted at 15°C for 10h; then raised the temperature to 130°C, 145°C, and 155°C for 1h each, and finally raised the temperature to 165°C and reacted at a constant temperature for 12h to obtain high-viscosity polyimide Amine solution with a solid content of 14%.

[0045] (2) Take the polyimide solution obtained in step (1) as the spinning solution, let it stand for defoaming, and prepare polyimide primary fibers by dry spinning technology, the tunnel temperature is 230 ° C, and the tunnel length is 10 m. The wire speed was 300 m / min.

[0046] (3) In a nitrogen atmosphere, the polyimide fiber obtaine...

Embodiment 3

[0049] (1) Under the protection of nitrogen, in a three-necked flask, successively add 300mL of NMP, 13.92g (0.062mol) of 2-(4-aminophenyl)-5-aminobenzimidazole (BIA), 3.92g (0.016mol) mol) of 3,5-diaminobenzoyl-3-amine-benzocyclobutene (synthesis method such as U.S. Patent 6,534,250[P].2003-3-18.), after stirring for 1h, add 25.0g (0.0776mol ) of 3,3',4,4'-benzophenonetetraacid dianhydride, stirred and reacted at 20°C for 10h; then raised the temperature to 130°C, 145°C, and 155°C for 1h each, and finally raised the temperature to 185°C for constant temperature reaction After 10 hours, a high-viscosity polyimide solution with a solid content of 12.5% was obtained.

[0050] (2) Take the polyimide solution prepared in step (1) as the spinning solution, let it stand for defoaming, and take solidification as the volume ratio of 6:4 NMP and deionized water as the coagulation bath, and deionized water as the water system bath, adopt dry jet-wet spinning technology to prepare pol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com