EKS and acrylic two-ingredient blend fiber product quantitative chemical analysis method

A technology of blended fiber and Yixie, which is applied in the field of textile inspection and testing, can solve the problems of no research and development, no report of Yixie fiber, etc., and achieve the effect of small error, good balance and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

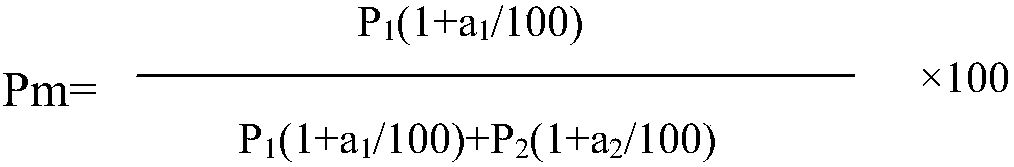

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: the first group of balance tests

[0035] 1. Reagents

[0036] All reagents are analytically pure, and the test water is the third-grade water in the national standard GB6682.

[0037] 1. Petroleum ether: the heating process is 40-60°C;

[0038] 2. Dilute acetic acid solution: add 5 mL of glacial acetic acid and dilute to 1 L with water;

[0039] 3. Sodium hypochlorite solution: molar concentration 0.45-0.55mol / L.

[0040] 2. Instrument

[0041] 1. Soxhlet extractor: receiving bottle 250mL;

[0042] 2. Constant temperature oscillator: the temperature adjustment range is from room temperature to 99°C;

[0043] 3. Vacuum pump: the speed is 1400r / min;

[0044] 4. Electric blast drying oven: keep the temperature at 105±3°C;

[0045] 5. Erlenmeyer flask with stopper: capacity 250mL;

[0046] 6. Glass sand core funnel: capacity 30mL ~ 50mL, pore diameter 90μm ~ 150μm;

[0047] 7. Dryer: equipped with color-changing silica gel;

[0048] 8. Weighing bott...

Embodiment 2

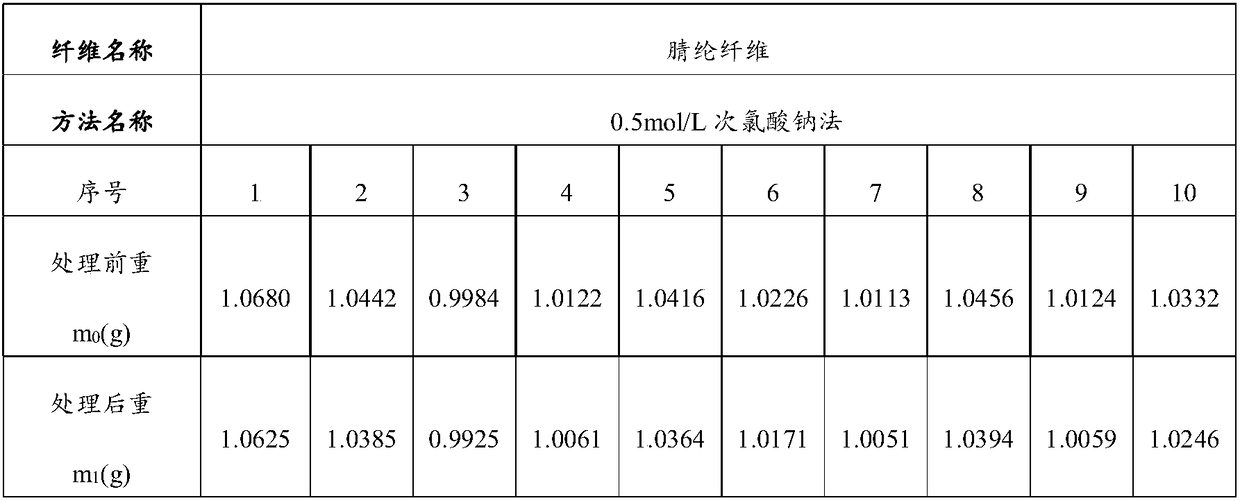

[0071] Embodiment 2: the second group of balance tests

[0072] Test data and calculated results are shown in Table 4, and others are the same as in Example 1.

[0073] Table 4 The second group of balance test results

[0074]

[0075]

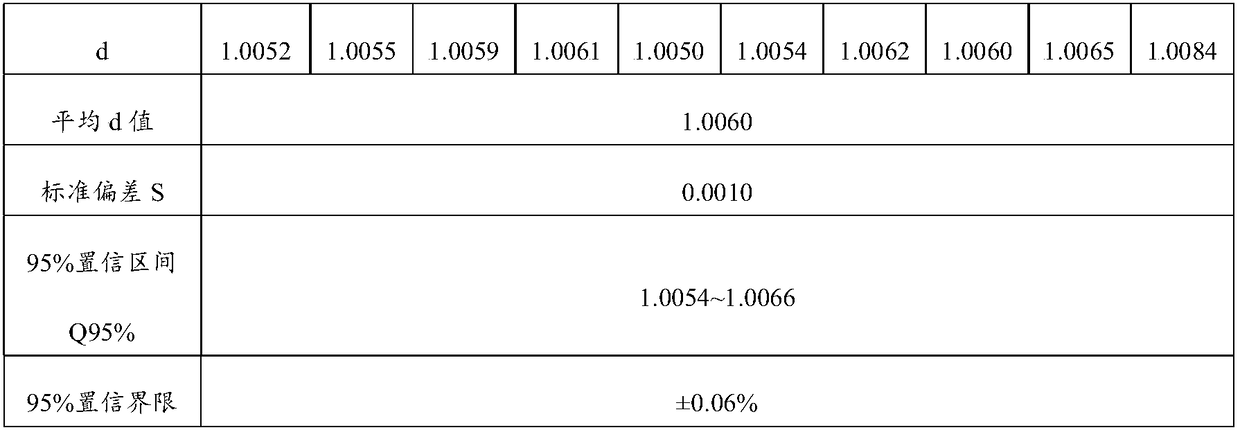

[0076] The calculation results combined with the public moisture regain are shown in Table 5.

[0077] Table 5 The content of the second group of balance tests combined with the public moisture regain (%)

[0078] Weighing bottle number

Embodiment 3

[0079] Embodiment 3: the third group of balance tests

[0080] Test data and calculated results are shown in Table 6, and others are the same as in Example 1.

[0081] Table 6 The third group of balance test results

[0082] Weighing bottle number

5

6

Weighing bottle + sample weight (g) G 1

30.3036

29.8524

Weighing bottle weight (g) G 2

29.3032

28.8490

Sample dry weight m 0 (g)(G 1 -G 2 =m 0 )

1.0004

1.0034

(weighing bottle + remaining sample) weight (g) G 3

30.0295

29.555

Dry weight of remaining sample m 1 (g)(G 3 -G 2 =m 1 )

0.7263

0.7265

Remaining sample (acrylic fiber) content (%) (100m 1 / m 0 )

72.6

72.4

dAcrylic fiber net dry content after correction (%) (P 1 =100dm 1 / m 2 )

73.0

72.8

d Corrected EKS net dry content (%) (P 2 =100-P 1 )

27.0

27.2

[0083] The calculation results combined with the public moisture re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| percent by volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com