Electrical bushing

A bushing and electric power technology, which is applied in the direction of pipes, rigid pipes, pipe supports, etc., can solve problems affecting the normal operation of the power system, bushing burnout and breakdown, bushing discharge arcing, etc., to reduce bushing discharge arcing phenomenon, reducing partial discharge, and eliminating air gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

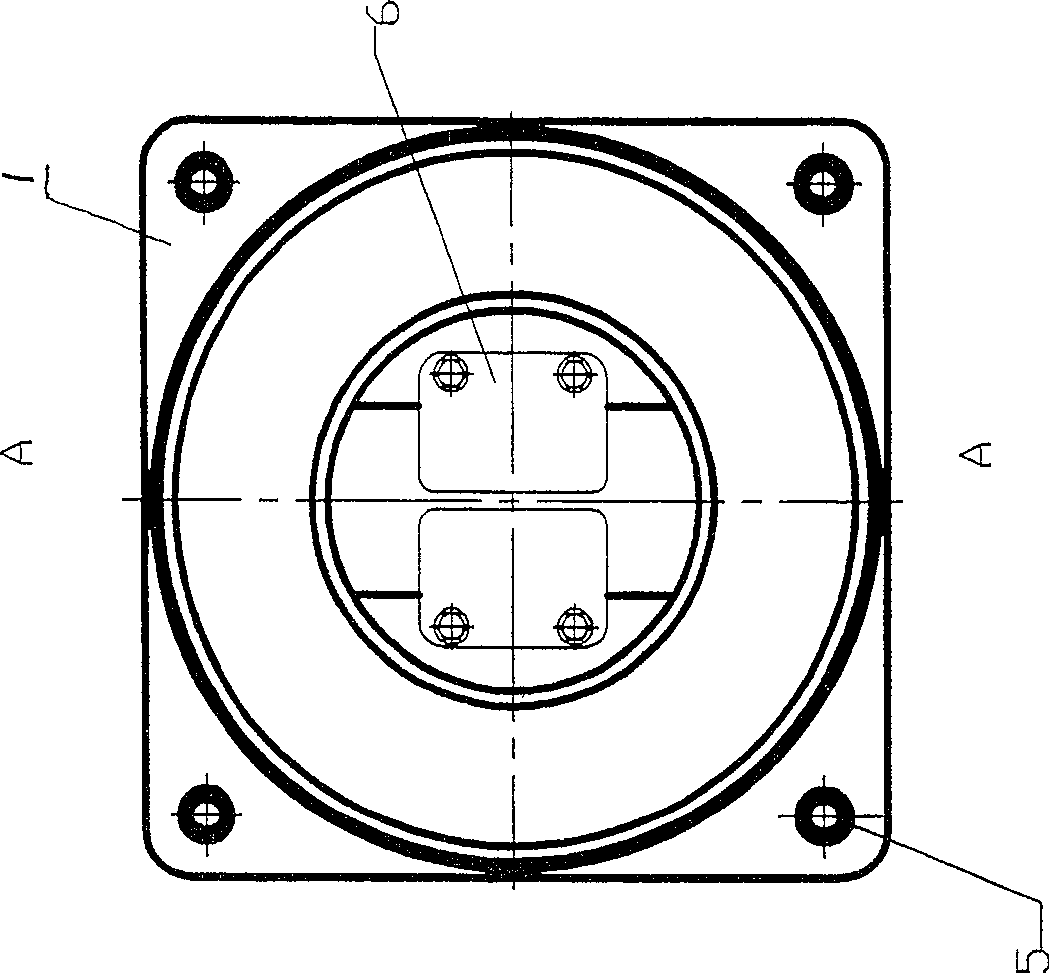

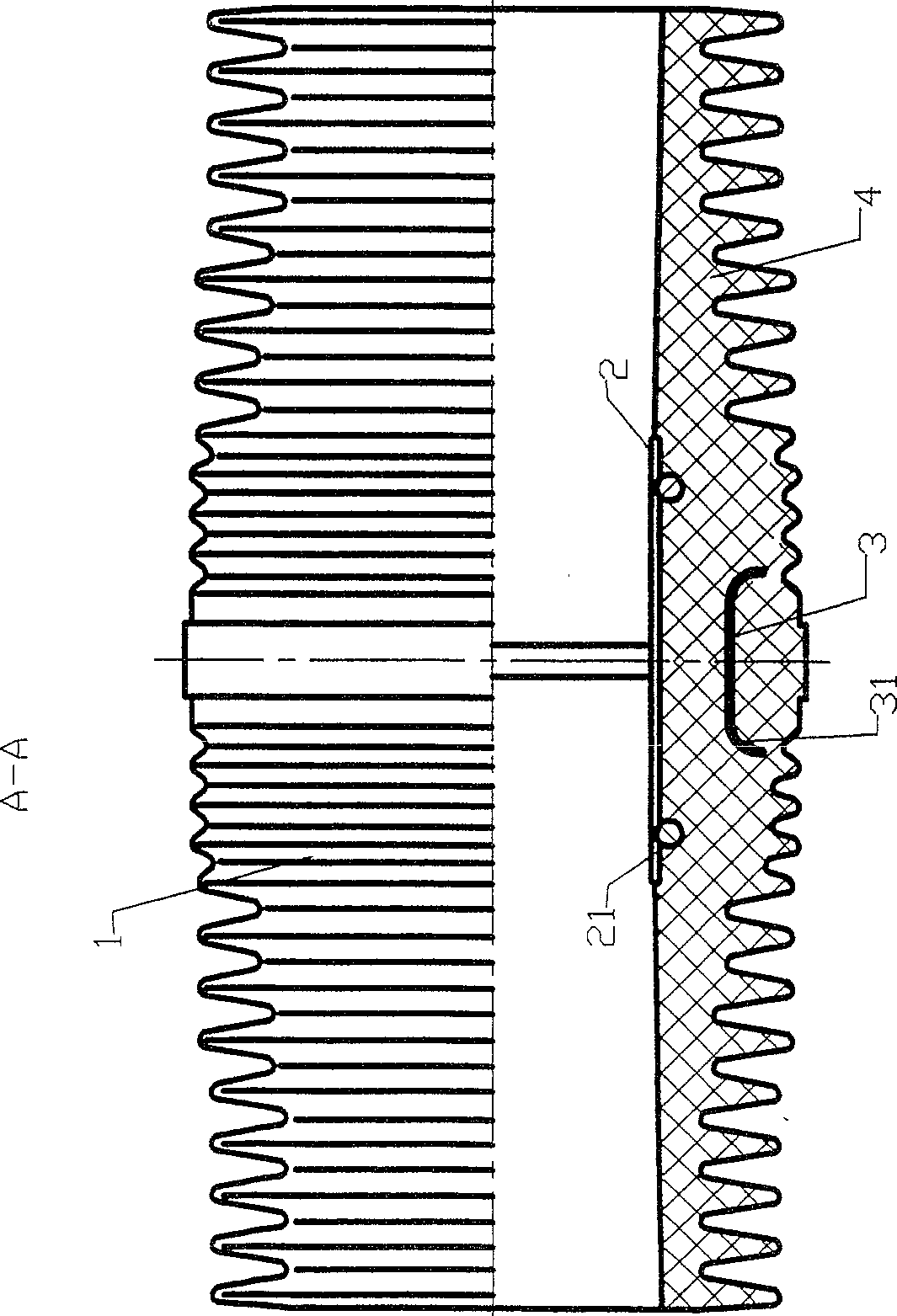

[0018] figure 1 , figure 2 An embodiment of an electrical bushing of the present invention is shown. It includes a body 1 with a thick layer of epoxy resin mixture 4, a busbar runs through the body, and the body 1 is provided with a grounding piece 5 and a spring leaf 6; the inner wall of the body 1 is provided with a busbar grading ring 2, the The equalizing ring 2 is poured into the thick epoxy resin mixture layer 4 of the body 1 . The pressure equalizing ring 2 is provided with a spring piece 6, and the pressure equalizing ring 2 is in contact with the busbar through the spring piece 6, in order to eliminate the air gap discharge between the inside of the bushing 1 and the busbar, and prevent air gap breakdown.

[0019] In the thick layer 4 of epoxy resin mixture of the body 1 a ground screen shielding ring 3 is embedded longitudinally ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com