Highly effective sterilization metallurgy sewage treatment method

A sewage treatment method and high-efficiency technology, which are applied in the fields of metallurgical wastewater treatment, sterilization/microdynamic water/sewage treatment, water/sewage multi-stage treatment, etc. Affect the normal operation of reverse osmosis and other issues, to save the cost of chemical cleaning, prolong the chemical cleaning cycle, and improve the effect of sterilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

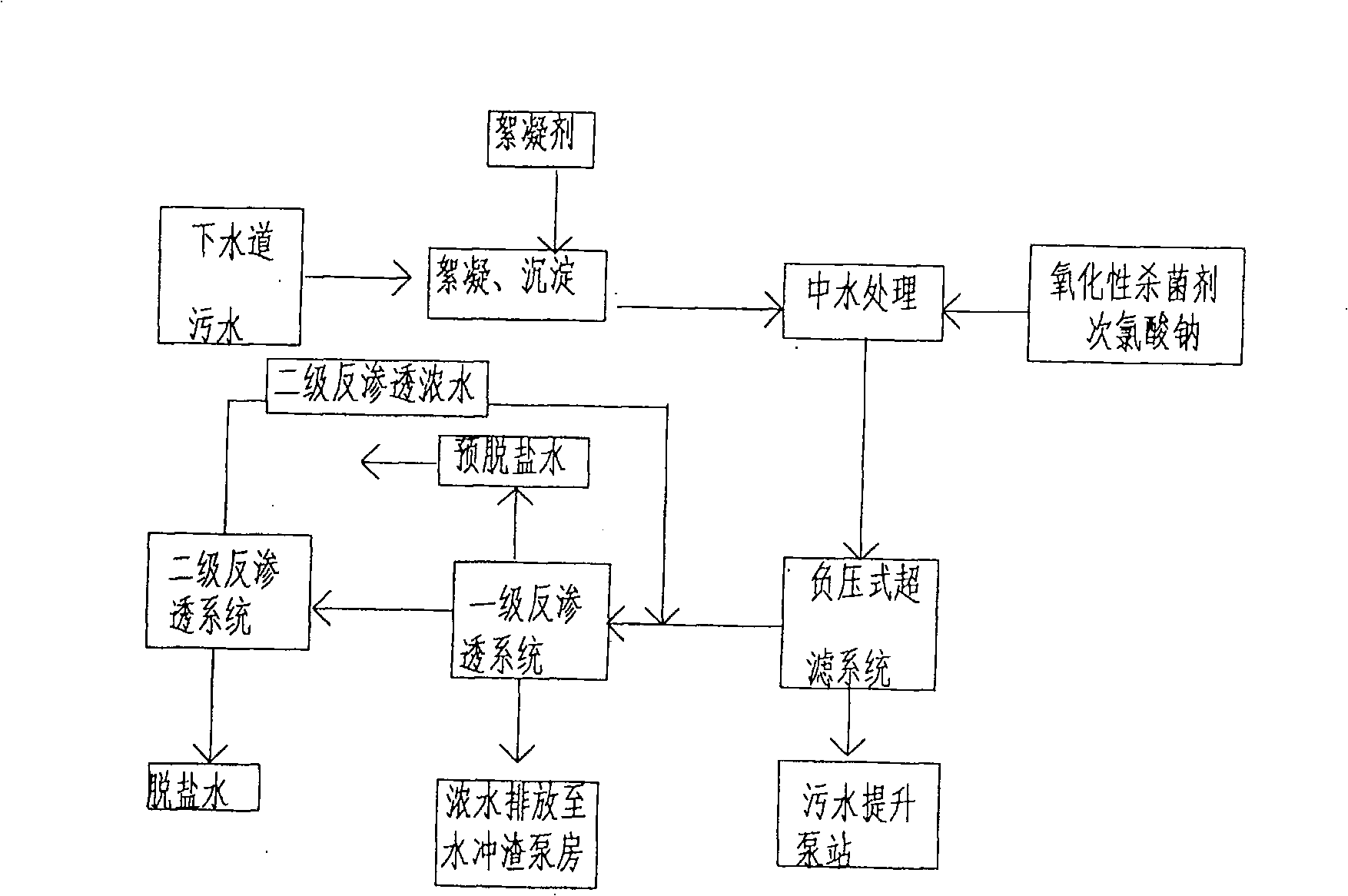

[0033] A. Recycle sewage and produce reclaimed water: take sewage from metallurgical industry sewers, and after flocculation and sedimentation, meet the reclaimed water requirement that the effluent suspended matter is less than 100mg / l;

[0034] B. One-time sterilization: filter the above-mentioned reclaimed water through a 1mm grid filter, and add oxidizing bactericide sodium hypochlorite for sterilization and disinfection, the main function is to inhibit the growth of bacteria and microorganisms. The dosage is 2mg / l.

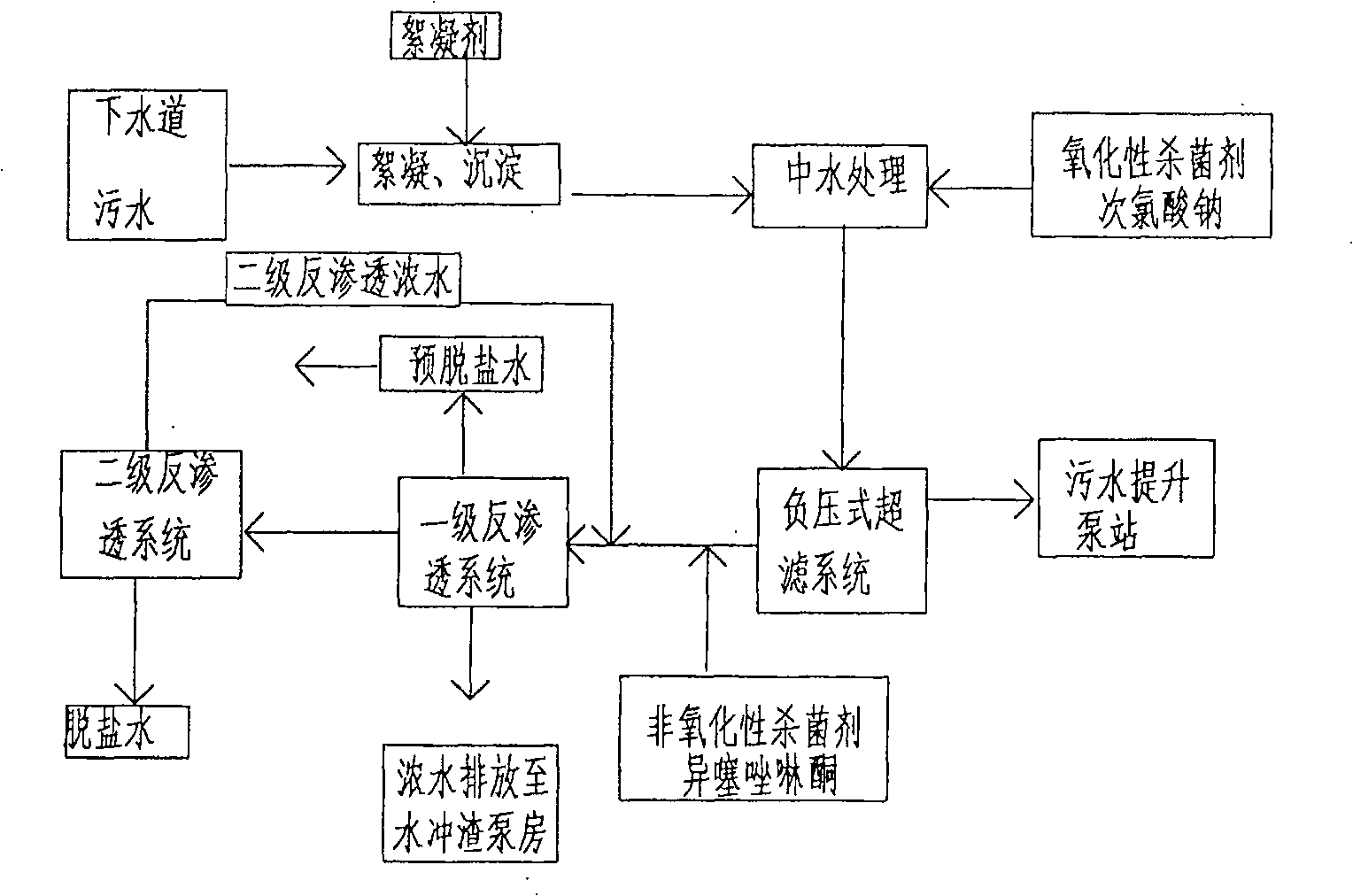

[0035] C. Ultrafiltration treatment and secondary sterilization: After the reclaimed water treated in step B is subjected to ultrafiltration treatment, the SDI is less than 3, and a non-oxidative bactericide isothiazolinone is added to the ultrafiltration jellyfish tube for secondary sterilization , to reduce the content of bacteria and microorganisms in the reverse osmosis water and extend the chemical cleaning cycle of reverse osmosis. The water temperatur...

Embodiment 2

[0038] A. Recycle sewage and produce reclaimed water: take sewage from metallurgical industry sewers, and after flocculation and sedimentation, meet the reclaimed water requirement that the effluent suspended matter is less than 100mg / l;

[0039] B. One-time sterilization: filter the above-mentioned reclaimed water through a 1mm grid filter, and add oxidizing bactericide sodium hypochlorite for sterilization and disinfection, the main function is to inhibit the growth of bacteria and microorganisms. The dosage is 3mg / l.

[0040] C. Ultrafiltration treatment and secondary sterilization: After the reclaimed water treated in step B is subjected to ultrafiltration treatment, the SDI is less than 3, and a non-oxidative bactericide isothiazolinone is added to the ultrafiltration jellyfish tube for secondary sterilization , to reduce the content of bacteria and microorganisms in the reverse osmosis water and extend the chemical cleaning cycle of reverse osmosis. The water temperatur...

Embodiment 3

[0043] A. Recycle sewage and produce reclaimed water: take sewage from metallurgical industry sewers, and after flocculation and sedimentation, meet the reclaimed water requirement that the effluent suspended matter is less than 100mg / l;

[0044] B. One-time sterilization: filter the above-mentioned reclaimed water through a 1mm grid filter, and add oxidizing bactericide sodium hypochlorite for sterilization and disinfection, the main function is to inhibit the growth of bacteria and microorganisms. The dosage is 2.5mg / l.

[0045] C. Ultrafiltration treatment and secondary sterilization: After the water in step B is treated by ultrafiltration, the SDI is less than 3, and the non-oxidative bactericide isothiazolinone is added to the ultrafiltration water-producing mother pipe for secondary sterilization to Reduce the content of bacteria and microorganisms in reverse osmosis water and prolong the chemical cleaning cycle of reverse osmosis. The water temperature is 31°C, the dosin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com