Functional type corn seed fertilizer, and preparation method

A corn seed, functional technology, applied in nitrogen fertilizer, potash fertilizer, phosphate fertilizer and other directions, to achieve the effect of more seedling roots, increase content, stimulate growth and development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Raw material (parts by weight): monoammonium phosphate (containing N: 11%, containing P 2 O 5 : 44%) 10 parts, ordinary calcium (also known as superphosphate containing P 2 O 5 : 16%) 56.9 parts, ammonium sulfate (containing N: 21%) 10 parts, ammonium bicarbonate (containing N: 17%) 15 parts, potassium sulfate 8 parts, appropriate amount of water, diethyl aminoethyl hexanoate (also called caproic acid) Diethylaminoethanol ester, DA-6) 0.04 parts, talc 0.7 parts, carbofuran (2,3-dihydro-2,2-dimethylbenzofuran-7-ylmethyl carbamate) 0.1 part.

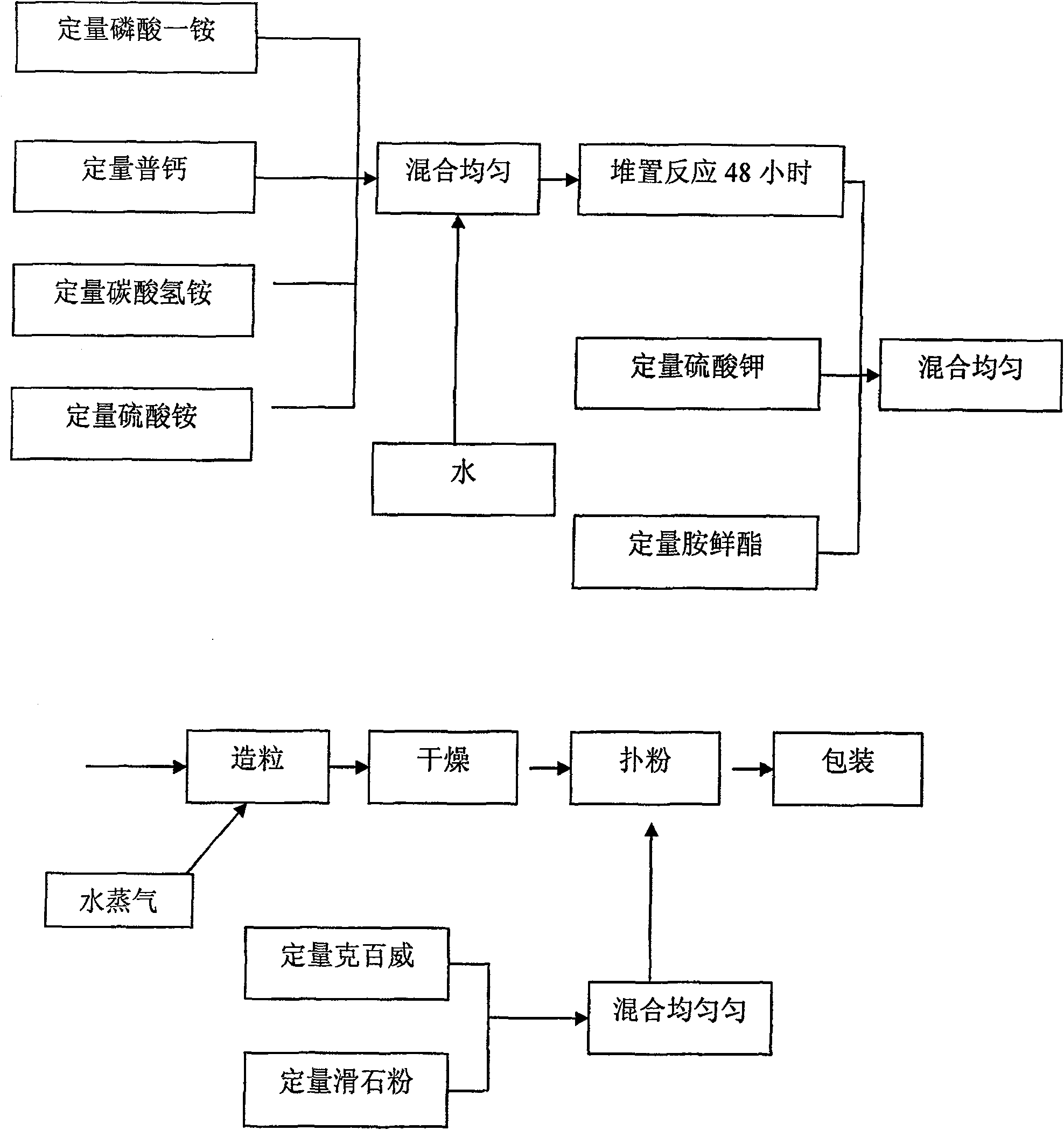

[0013] After mixing a proper amount of monoammonium phosphate, general calcium, ammonium sulfate, ammonium bicarbonate, and water (the mixture feels damp when grasped by hands), stack it for 48 hours, then mix it with potassium sulfate and diethyl aminoethyl hexanoate and send it to the manufacturing plant. The granulator is sprayed with water vapor for granulation, and after drying, it is made with a mixed puff powder of talc and carbo...

Embodiment 2

[0015] Raw material (parts by weight): ordinary calcium (including P 2 O 5 : 16%) 1 part, monoammonium phosphate (containing N: 11%, P 2 O 5 : 44%) 50 parts, ammonium sulfate (including N: 21%) 19 parts, ammonium bicarbonate (including N: 17%) 10 parts, appropriate amount of water, potassium sulfate (including K 2 O: 50%) 20 parts, 0.05 parts of diethyl aminoethyl hexanoate, 0.8 parts of talc, and 0.15 parts of carbofuran.

[0016] After mixing a proper amount of calcium, monoammonium phosphate, ammonium sulfate, ammonium bicarbonate, and water (the mixture feels damp when grasped by hand), stack it for 48 hours, and then mix it with potassium sulfate and diethyl aminoethyl hexanoate and send it to the manufacturing plant. The granulator is sprayed with water vapor for granulation, and after drying, it is made with a mixed puff powder of talc and carbofuran (the process is shown in the figure), that is, N: 12%, P 2 O 5 : 24%, K 2 O: 10% seed fertilizer.

Embodiment 3

[0018] Raw material (parts by weight): ordinary calcium (including P 2 O 5 : 16%) 1 part, monoammonium phosphate (containing N: 11%, P 2 O 5 : 44%) 70 parts, ammonium sulfate (including N: 21%) 1 part, ammonium bicarbonate (including N: 17%) 14 parts, appropriate amount of water, potassium sulfate (including K 2 O: 50%) 13.1 parts, diethyl aminoethyl hexanoate 0.04 parts, talc 0.7 parts, carbofuran 0.13 parts.

[0019] After mixing a proper amount of calcium, monoammonium phosphate, ammonium sulfate, ammonium bicarbonate, and water (the mixture feels damp when grasped by hand), stack it for 48 hours, and then mix it with potassium sulfate and diethyl aminoethyl hexanoate and send it to the manufacturing plant. The granulator is sprayed with water vapor for granulation, and after drying, it is made with a mixed puff powder of talc and carbofuran (the process is shown in the figure), that is, N: 12%, P 2 O 5 : 35%, K 2 O: 7% seed fertilizer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com