Iron contact dephosphorization device and method

A technology of plates and components, applied in the field of water treatment, to achieve the effects of reducing eutrophication, reducing the load of subsequent treatment processes, and efficiently removing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

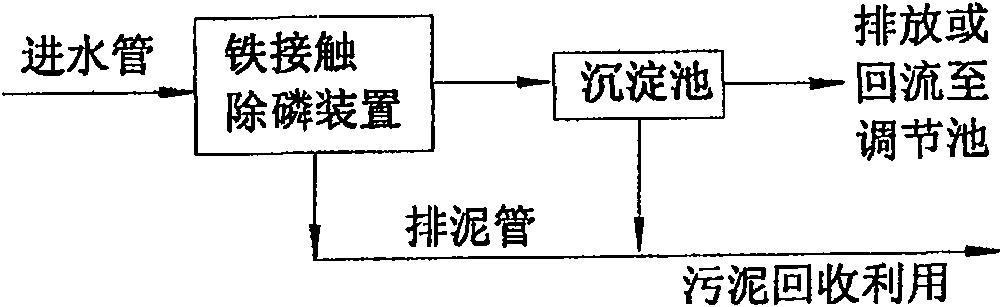

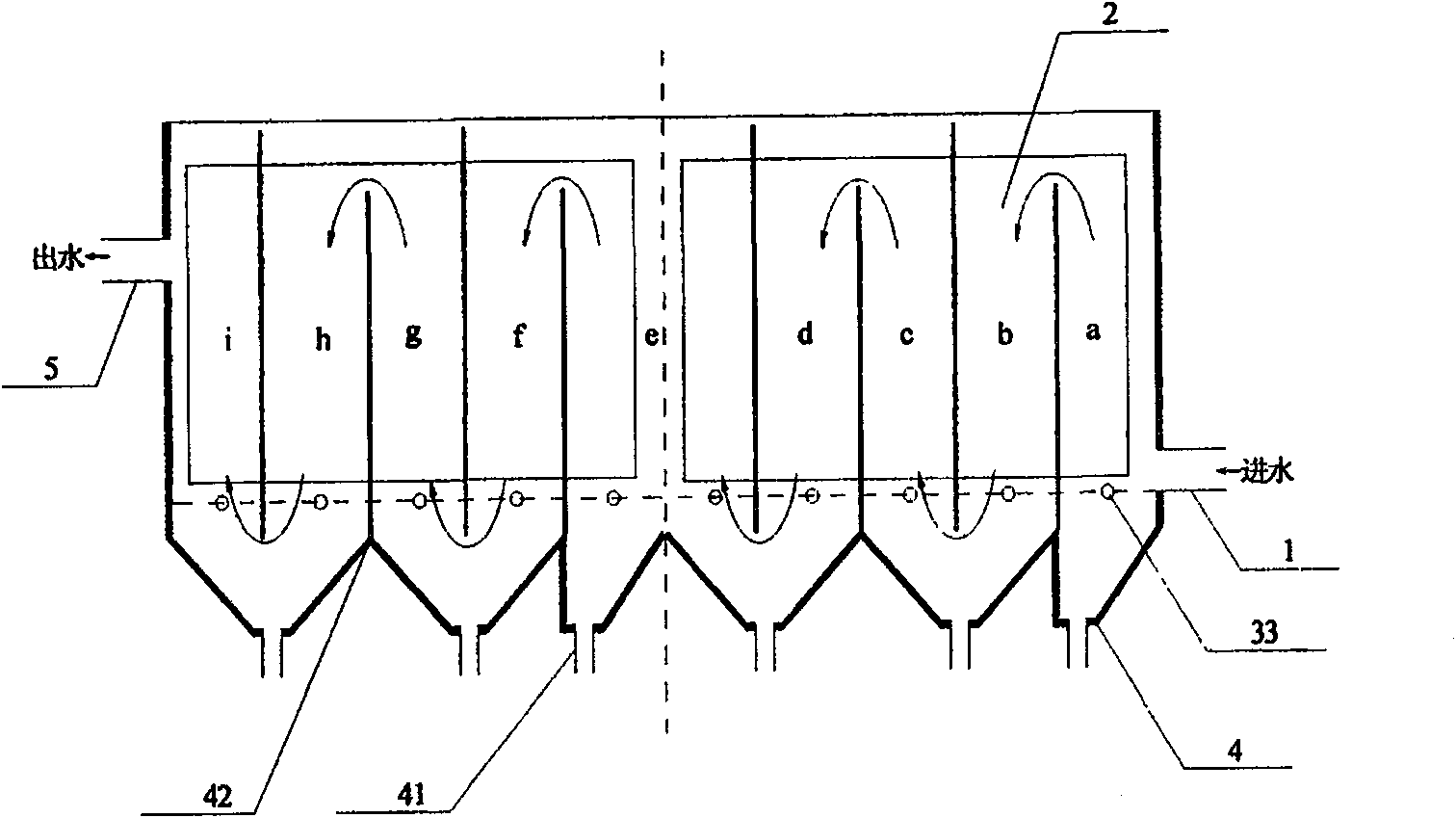

[0022] If the treatment of conventional urban sewage with a total phosphorus concentration of 3-7 mg / L (refer to figure 1 ), the iron contact dephosphorization method of the present invention refers to that conventional urban sewage enters the iron contact dephosphorization device through the water inlet pipe, and flows into the sedimentation tank after staying in the iron contact dephosphorization device for a certain period of time, and the sedimentation tank effluent can be directly discharged. The sludge from the iron contact phosphorus removal device and the sedimentation tank enters the subsequent sludge recycling system through the sludge pipe. The operation mode of the iron contact phosphorus removal device: adopt intermittent aeration mode, the ratio of aeration / stop time is 3 / 1~3 / 2, and the stop time should not exceed 30min, and the aeration intensity is 3~6m 3 / (m 3 h), the hydraulic retention time is 7 to 9 hours, the sludge discharge frequency is once every 2 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com