Low pressure low temperature gas-phase production method for ferromagnetism chromium oxide compound nano-grain film

A nanoparticle, chromium oxide technology, applied in chromium oxide/hydrate and other directions, can solve the problem of inability to obtain high-quality CrO2 films, and achieve the effects of good compatibility, high efficiency, and easy scale.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following is a typical step and working parameters for preparing ferromagnetic chromium oxide nanoparticle thin film by adopting this method:

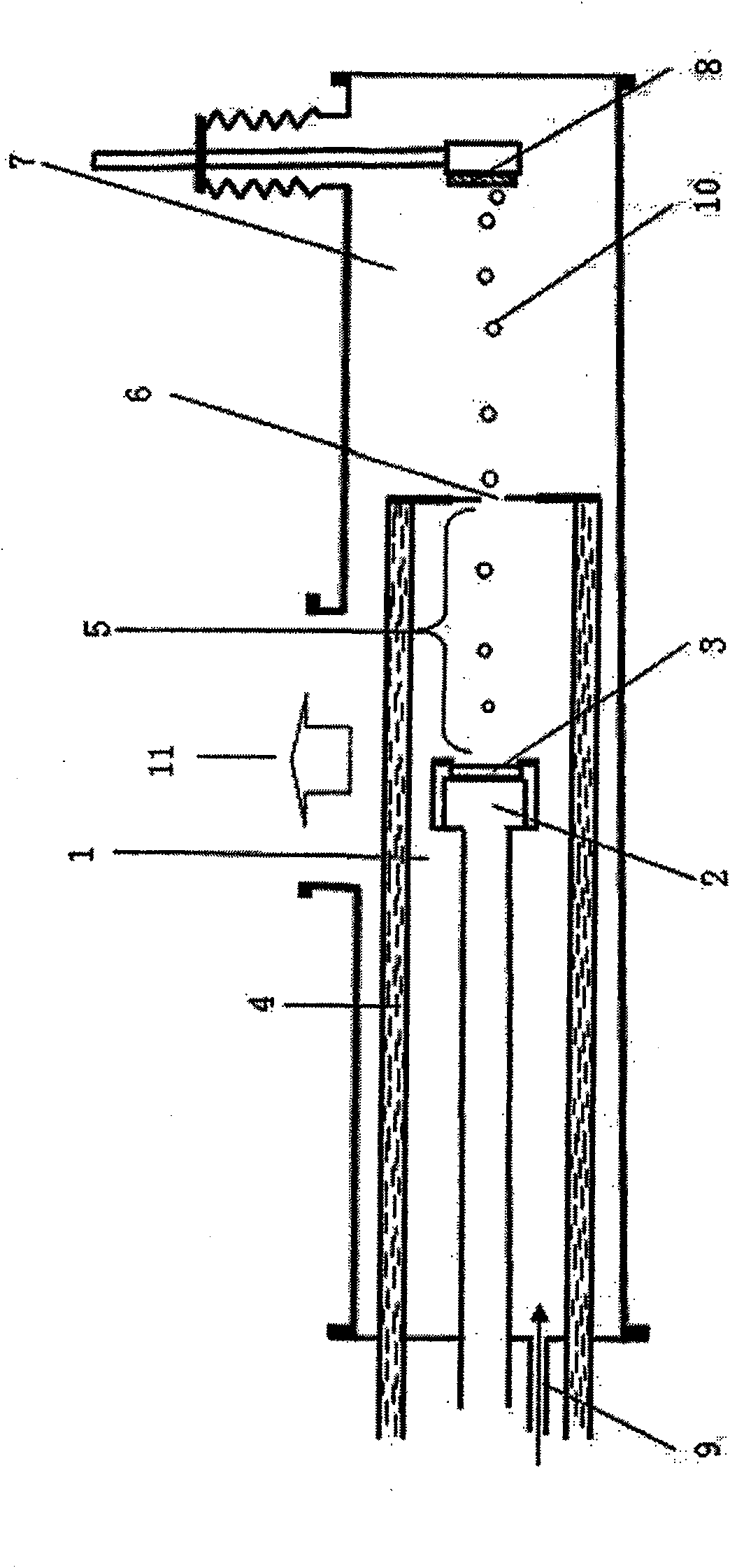

[0028] (1) if figure 1 As shown, the magnetron plasma sputtering is carried out in the condensation chamber (1) cooled by liquid nitrogen, and the sputtering target (3) - a high-purity metal chromium sheet with a diameter of 50 mm and a thickness of 3 mm is fixed on the magnetron sputtering target base (2), produce high-concentration Cr atom gas on the surface of the metal Cr target (3) by sputtering;

[0029](2) filling the condensation chamber (1) with a purity of 99.99% argon as a buffer gas from the gas filling pipe (9), the air pressure remains at a stable value of 200Pa;

[0030] (3) During the sputtering process, while filling the buffer gas, fill the condensation chamber (1) with 99.99% pure oxygen to oxidize Cr atoms, and the molecular ratio of oxygen to argon is controlled at 2% ;

[0031] (4) The power source o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com