Electric field purifying process of coal-tar oil

A technology of coal tar and electric field, applied in tar processing, petroleum industry, through electro/magnetic refining, etc., to prevent corrosion, avoid bed clogging, and prolong operation period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

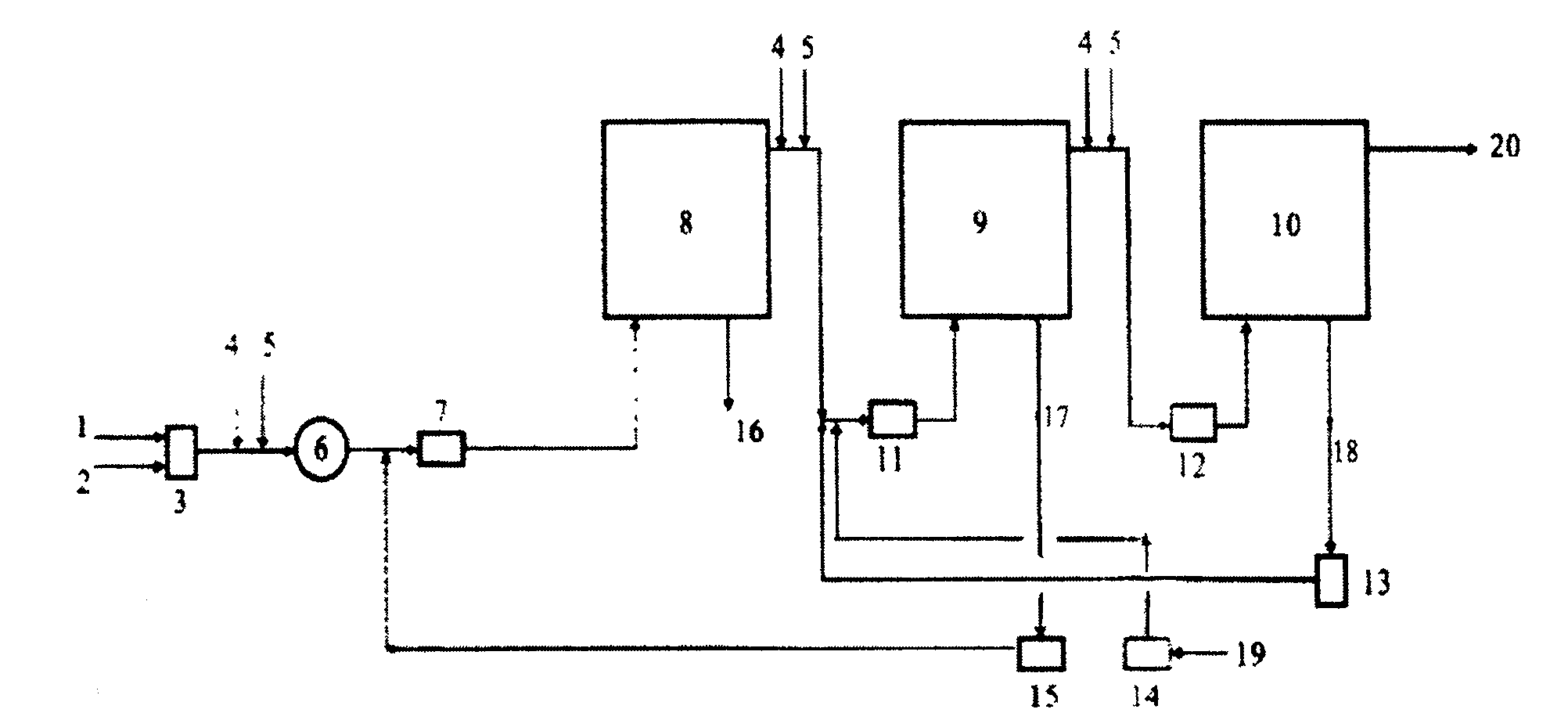

Method used

Image

Examples

Embodiment 1

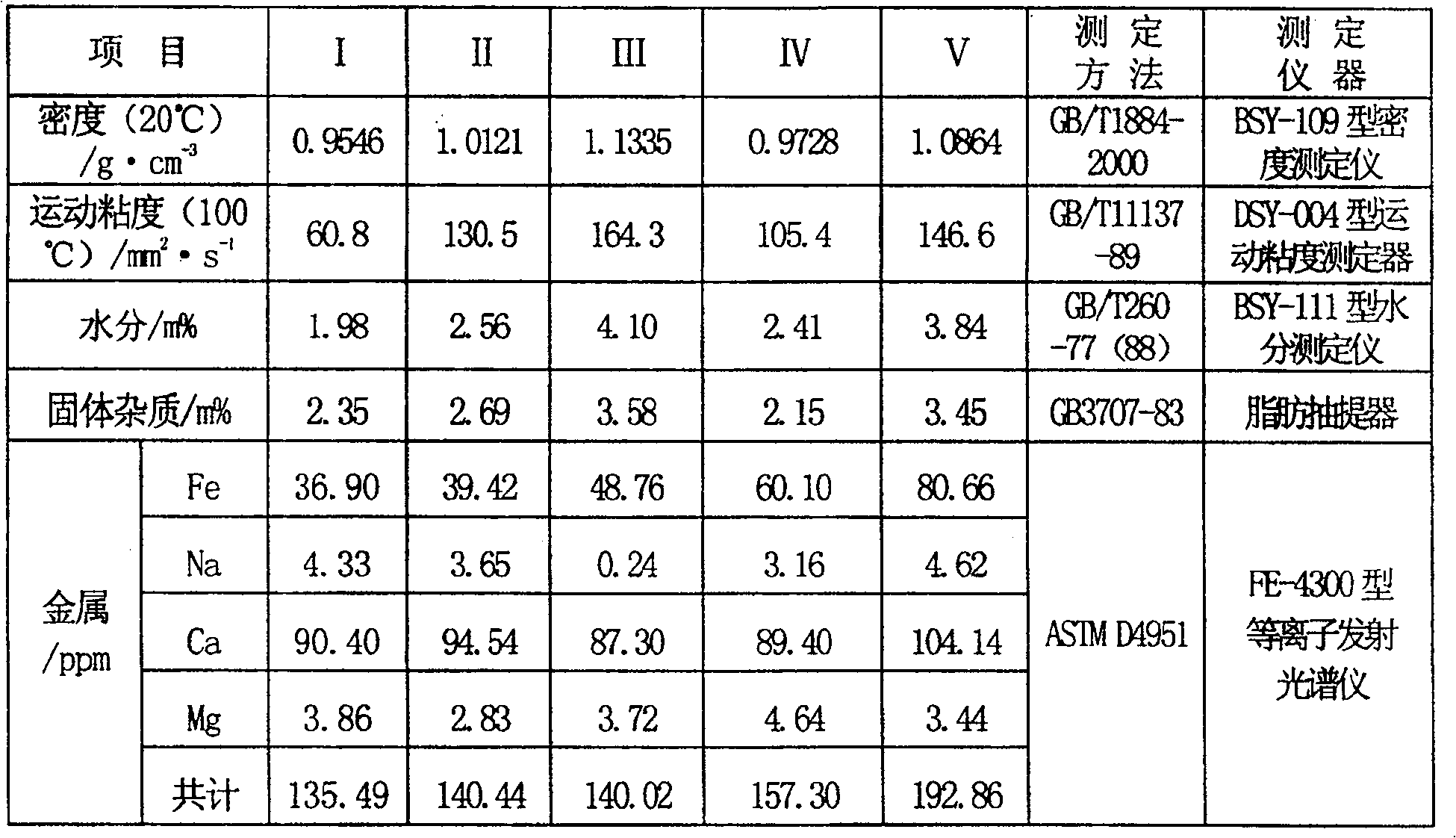

[0029] The coal tar 1 of the present embodiment is low-temperature coal tar, and taking purification of low-temperature coal tar 10kg as an example, its process steps are as follows:

[0030] 1. Preparation of mixed oil

[0031] Inject 7.5ppm of GQ-P5401 demulsifier 4 and 30ppm of QC01·061 demetallizer 5 into 10kg of low-temperature coal tar in the pipeline to make a mixed oil, enter the heater 6 through the pipeline, and heat it to 130°C.

[0032] 2. First-level electrolysis

[0033] The heated mixed oil enters the first-stage mixer 7, the pressure drop before and after the first-stage mixer 7, that is, the mixing intensity is 60KPa, and enters the first-stage electric detachment tank 8 through the first-stage mixer 7, and the first-stage electric detachment tank 8 exchanges The strong electric field intensity of the electric field is 800V / cm, the action time of the strong electric field is 4min, and the electric stripping temperature is 120°C. The primary electric stripping...

Embodiment 2

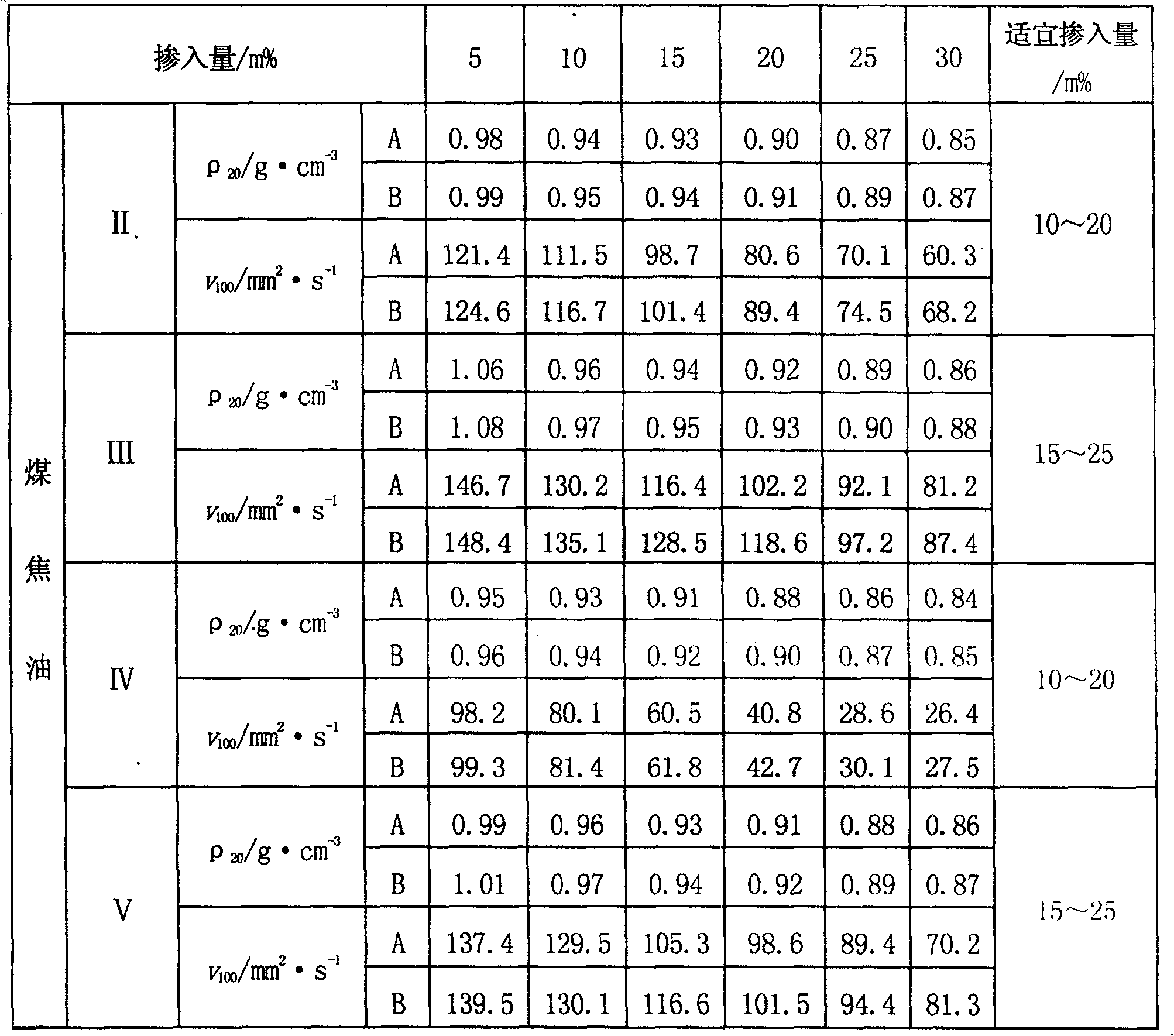

[0043] The coal tar 1 of the present embodiment is medium-temperature coal tar, and taking the purification of 10kg of medium-temperature coal tar as an example, its process steps are as follows:

[0044] 1. Preparation of mixed oil

[0045] Mix medium-temperature coal tar and hydrogenated oil at a weight ratio of 1:0.12 with a mixing pump 3. Hydrogenated oil is an example of diluent oil 2. Inject 8ppm into 10kg of medium-temperature coal tar in the pipeline. The model is GQ-P5401 Demulsifier 4 and 35ppm demetallizer 5 of model QC01·061 are made into mixed oil, which enters heater 6 through pipeline and is heated to 140°C.

[0046] 2. First-level electrolysis

[0047] The heated mixed oil enters the first-stage mixer 7, the pressure drop before and after the first-stage mixer 7, that is, the mixing intensity is 65KPa, and enters the first-stage electric detachment tank 8 through the first-stage mixer 7, and the first-stage electric detachment tank 8 exchanges The strong elec...

Embodiment 3

[0056] The coal tar 1 of the present embodiment is high-temperature coal tar, and taking purification high-temperature coal tar 10kg as example, its process steps are as follows:

[0057] 1. Preparation of mixed oil

[0058] Mix high-temperature tar and hydrogenated oil in a weight ratio of 1:0.15 with a mixing pump 3 in the pipeline, and inject 6ppm of demulsifier 4 of model GQ-P5401 and 26ppm of demulsifier 4 of model QC01·061 into 10kg of high-temperature coal tar in the pipeline The demetallizing agent 5 is made into mixed oil, which enters the heater 6 through the pipeline and is heated to 150°C.

[0059] 2. First-level electrolysis

[0060] The heated mixed oil enters the first-stage mixer 7, the pressure drop before and after the first-stage mixer 7, that is, the mixing intensity is 70KPa, and enters the first-stage electric detachment tank 8 through the first-stage mixer 7, and the first-stage electric detachment tank 8 exchanges The strong electric field strength of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com