Composition for bactericide production and process for producing organic peracid

A bactericide composition, technology of manufacturing method, applied in botany equipment and method, preparation of organic compound, preparation of peroxygen compound, etc., capable of solving problems such as hypochlorite corroding metal chlorine gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

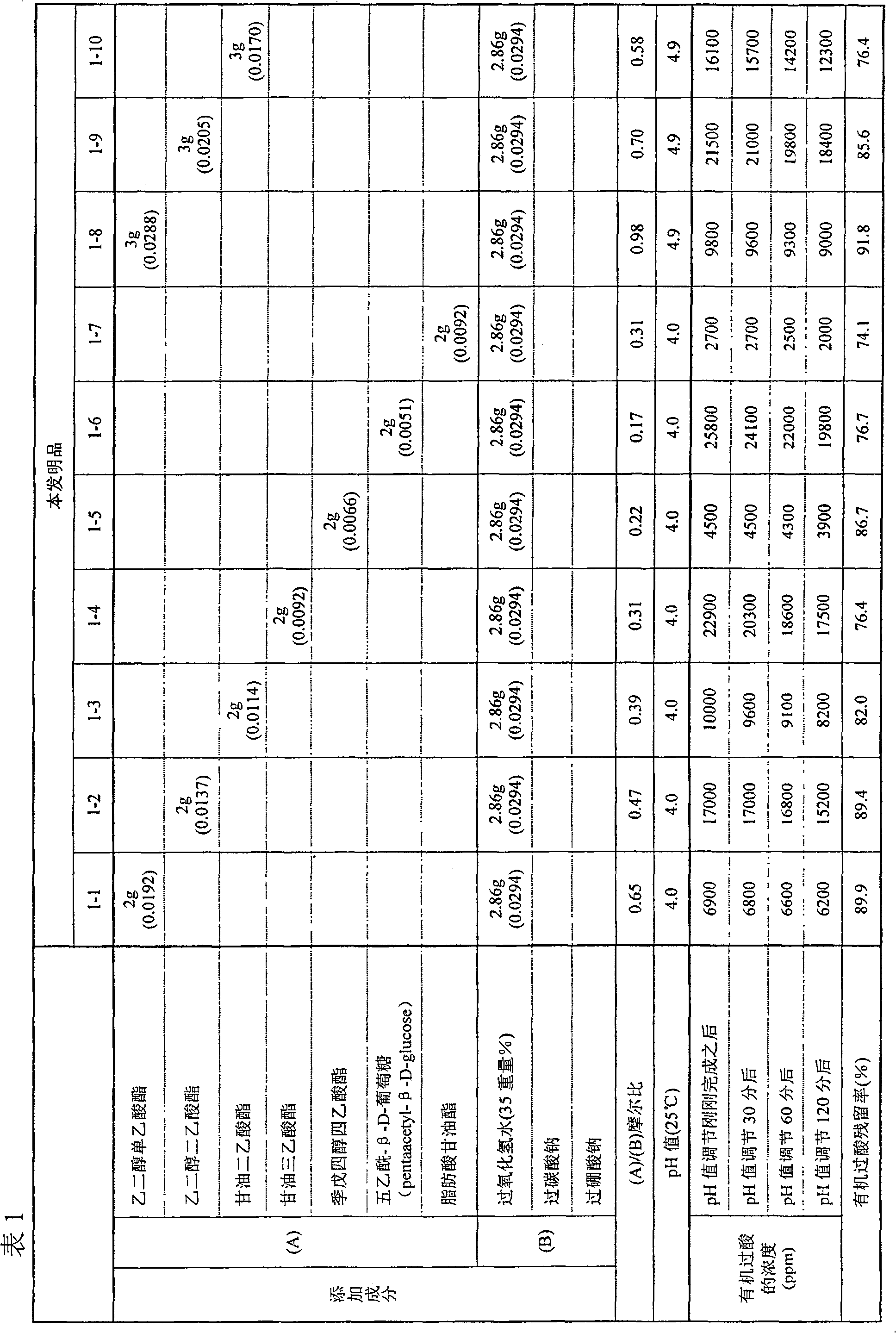

Embodiment 1

[0101] (A) component, (B) component, 50 g of ion-exchanged water, and an appropriate amount of alkaline pH adjuster (sodium carbonate) shown in Tables 1 to 5 were stirred and mixed in a 200 mL beaker for 20 minutes. Make the pH value at this time reach 8-12. Afterwards, an acidic pH regulator (citric acid) was used to adjust to the target pH to obtain a fungicide composition. The change with time of the concentration of the organic peracid at this time was measured. The concentration of organic peracids was determined by the following method. The results are shown in Tables 1-5.

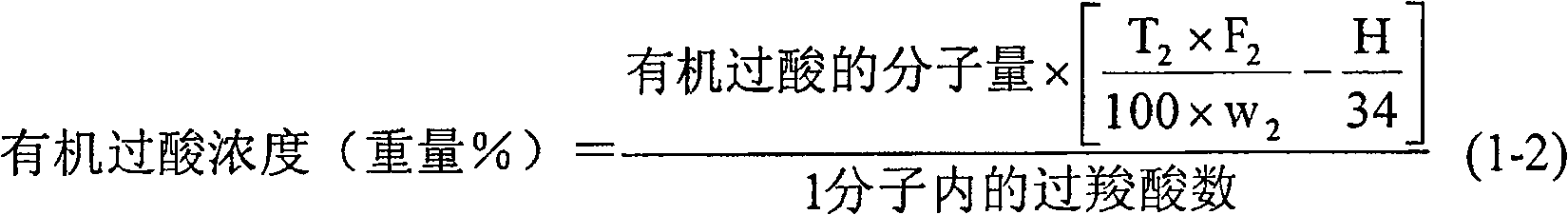

[0102] (1) Determination of the concentration of organic peracids

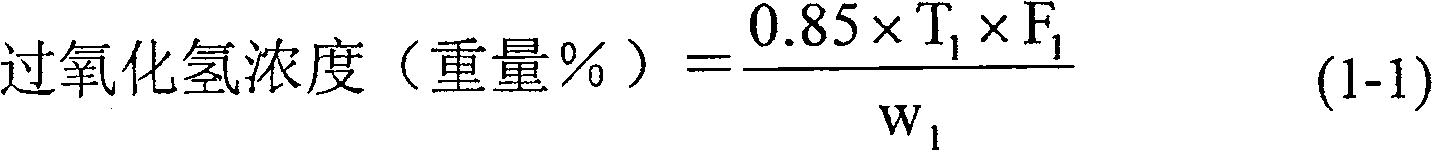

[0103] (1-1) Quantification of hydrogen peroxide

[0104] In a 200mL Erlenmeyer flask, accurately weigh w 1 gram bactericide composition (within the scope of 1~50 gram), add the 20% sulfuric acid aqueous solution of 10mL and 2~3 borneols to cool solution, after dripping 1~2 saturated manganese sulfate aqueous solution as catalys...

Embodiment 2

[0123]Stir and mix in a 200 mL beaker with (A) component, (B) component, 50 g of ion-exchanged water, and an appropriate amount of alkaline pH regulator (sodium carbonate) shown in Tables 6 to 9 for 20 minutes. Make the pH value at this time reach 8-12. Afterwards, an acidic pH regulator (citric acid) was used to adjust to the target pH to obtain a fungicide composition. Using the obtained bactericide composition, the bactericidal effect was measured by the following method. The results are shown in Tables 6-9.

[0124] (1) Killing effect of bacterial spores

[0125] Bacillus subtilis as a spore-forming bacterium ( Bacillus subtilis var.niger ) and Bacillus circulans ( Bacillus circulans IFO3967) were pre-cultured in SCD agar medium (manufactured by Nippon Pharmaceutical Co., Ltd.) at 30°C for about 4 weeks, and an appropriate amount of colonies formed on the agar medium was obtained, suspended in 1 mL of sterilized water, and examined with a microscope. Microscopy...

Embodiment 3

[0133] (A) component, (B) component, organic phosphonic acid (trade name: D イ Cuest 2010 (Solu-Siaji ヤ Pan Co., Ltd.) and alkaline pH adjuster were added with ion-exchanged water so that the total weight was 100 g. This was stirred and mixed in a 200 mL beaker for about 10 minutes. Make the pH value at this time reach 8-12. Thereafter, the acidic pH adjuster of the weight shown in Table 10 was quickly adjusted to the target pH, and ion-exchanged water was added to make the total amount 110 g. The concentration of the organic peracid and the concentration of hydrogen peroxide at this time (immediately after preparation) were measured, and the sterilizing aqueous solution about 30 minutes after the start of stirring was adjusted so that the concentration of the organic peracid was 3000 ppm, and the bactericidal effect was confirmed. In addition, although the method of measuring the concentration of hydrogen peroxide and the concentration of organic peracid is carried out acco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com