Surface treatment process for ultra-low friction film

A DLC film and surface treatment technology, applied in the field of ultra-low friction, can solve the problems of limited element composition, inconvenience of large-scale equipment and complex surfaces, easy segregation of compounds, etc., to achieve the effect of strong surface adaptability and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

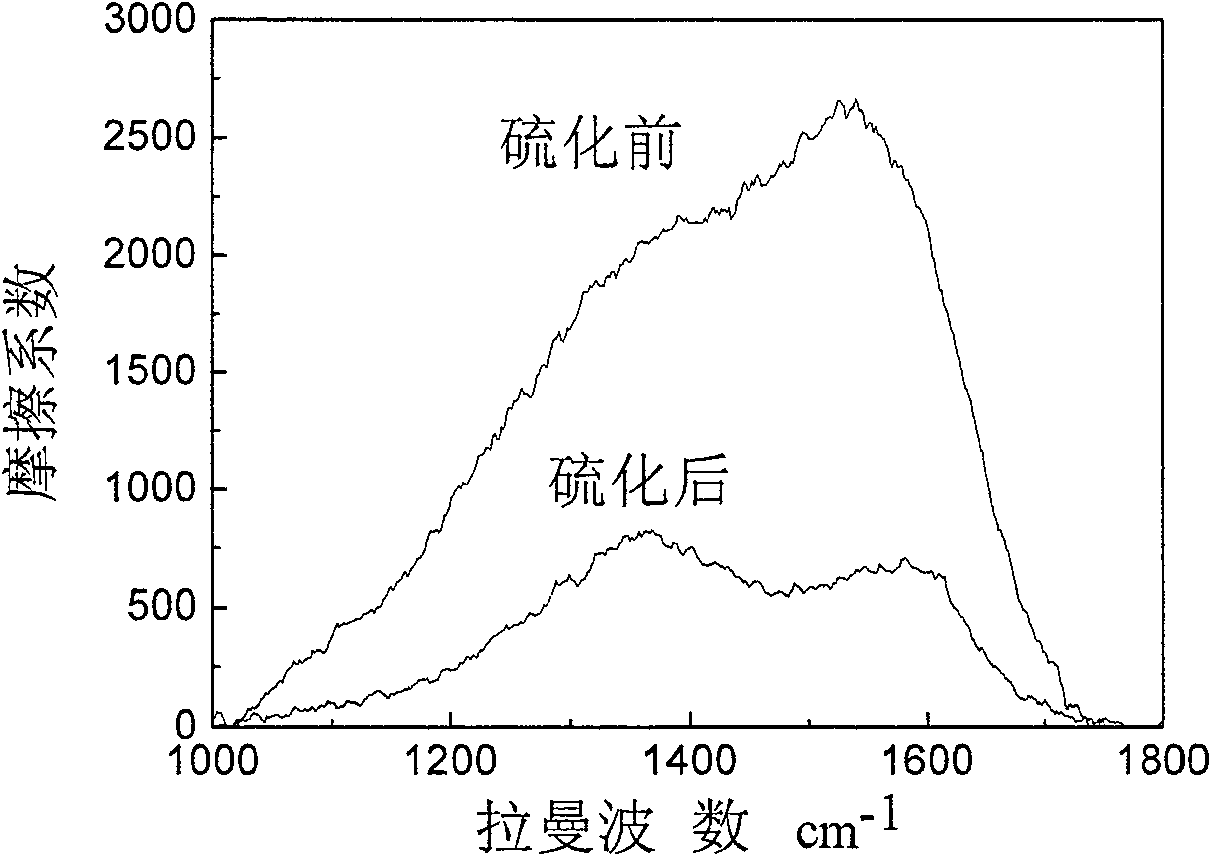

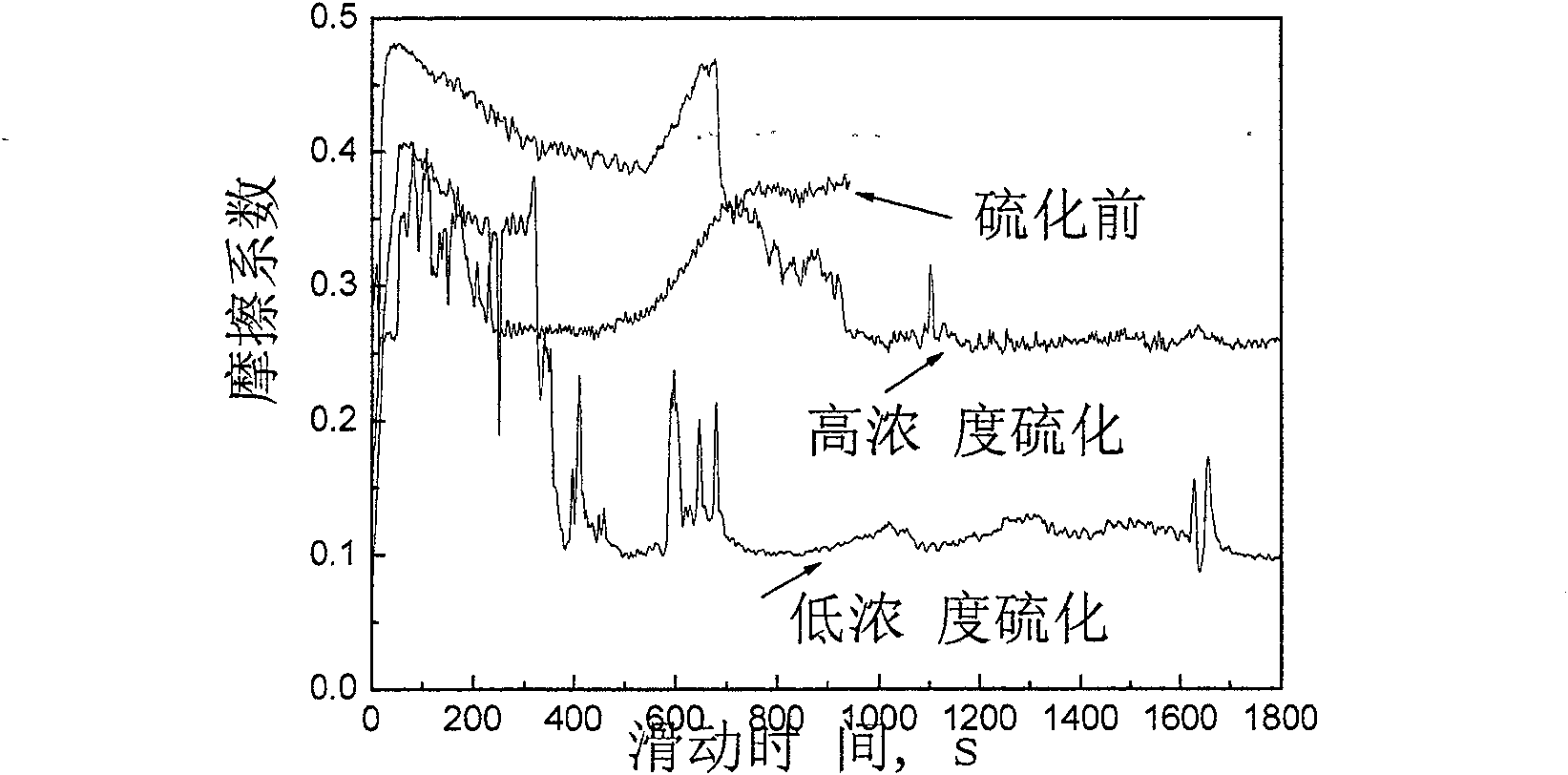

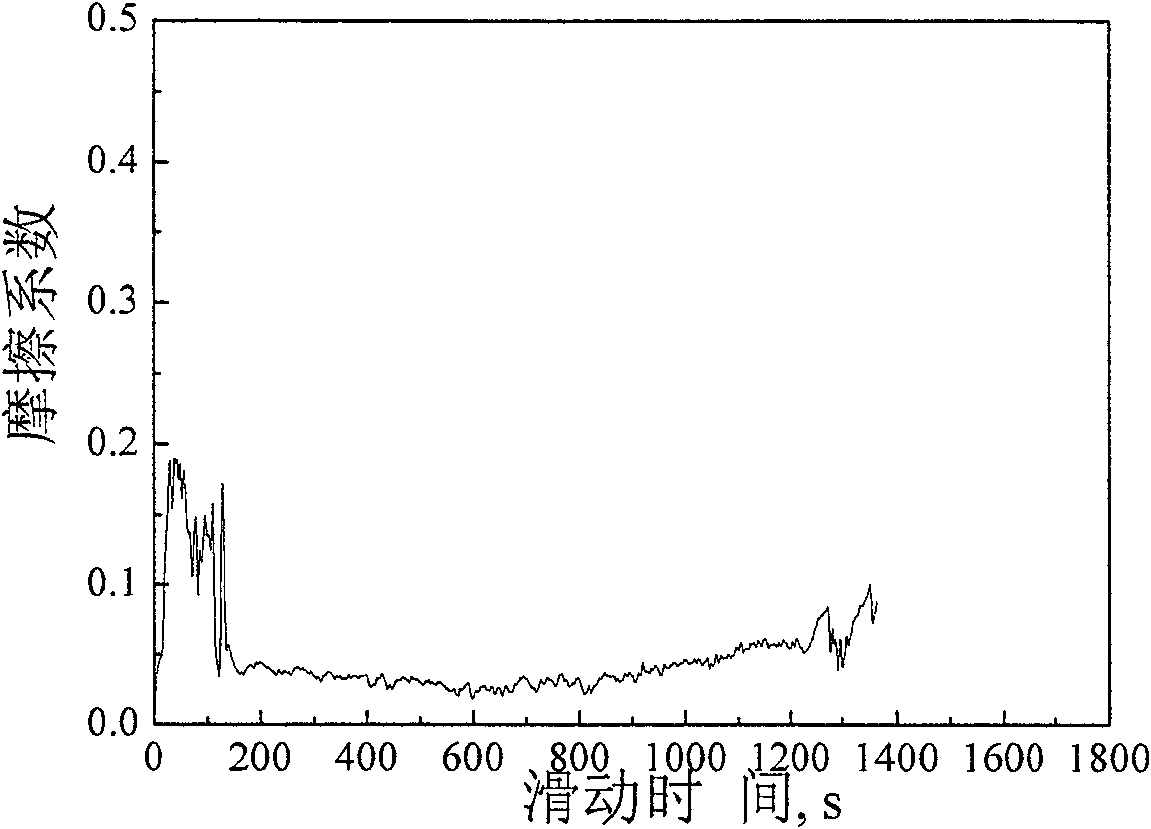

[0013] Example 1: First, the sulfur-containing organic compound ethanethiol is dissolved in distilled water as a vulcanizing agent to prepare a vulcanization solution with a concentration of 0.4g / ml, and then add its volume ratio to the vulcanization solution as 2% perfluorosurfactant Sodium perfluorononyloxybenzene sulfonate; secondly, place the DLC film in a vulcanization solution, and electrolyze it for 2-10 hours at a voltage of 500V and a frequency of 50Hz, until the DLC film becomes gray and evenly distributed on the substrate; finally , put the electrolyzed sample in a vacuum chamber at a vacuum degree of 6×10 -2 At Pa, heat up to 350°C for vacuum annealing and then cure.

Embodiment 2

[0014] Embodiment 2: First, the sulfur-containing organic compound dimethyl sulfone is dissolved in distilled water as a vulcanizing agent to prepare a vulcanization solution with a concentration of 0.6g / ml, and then add its volume ratio to the vulcanization solution as 4% perfluorosurfactant agent perfluoroalkyl ethoxy ether alcohol non-ionic fluorine surfactant; secondly, place the DLC film in a vulcanization solution, and electrolyze it for 2-10 hours at a voltage of 300V and a frequency of 30Hz to make the DLC film form on the substrate until the gray is evenly distributed; finally, place the electrolyzed sample in a vacuum chamber at a vacuum degree of 6×10 -2 At Pa, heat up to 320°C for vacuum annealing and then cure.

Embodiment 3

[0015] Example 3: First, the sulfur-containing organic compound dimethyl sulfoxide is dissolved in distilled water as a vulcanizing agent to prepare a vulcanization solution with a concentration of 0.9g / ml, and then a perfluorinated surface with a volume ratio of 1% is added to the vulcanization solution. The active agent perfluorooctanesulfonyl fluoride; secondly, place the DLC film in a vulcanization solution, and electrolyze it for 2-10 hours at a voltage of 100V and a frequency of 70Hz, until the DLC film becomes gray and evenly distributed on the substrate; finally, Place the electrolyzed sample in a vacuum chamber at a vacuum degree of 6×10 -2 At Pa, heat up to 370°C for vacuum annealing and then cure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com