Environment protecting type coal surface solidifying agent and preparation process thereof

An environmentally friendly, curing agent technology, applied in chemical instruments and methods, other chemical processes, loading/unloading, etc., can solve problems such as discharge, physical health hazards, deterioration of the environment of employees and passengers, achieve huge economic benefits, and avoid dust. The effect of pollution, environmental protection and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Raw material ratio:

[0034] Raw material ratio (wt%) Raw material ratio (wt%)

[0035] Polyvinyl alcohol 1 10wt% hydrogen peroxide solution 0.3

[0036] Starch 5 5wt% borax or boric acid solution 2

[0037] Ferrous sulfate 0.005 10wt% caustic soda solution 4

[0038] water 87.695

[0039] Operation process:

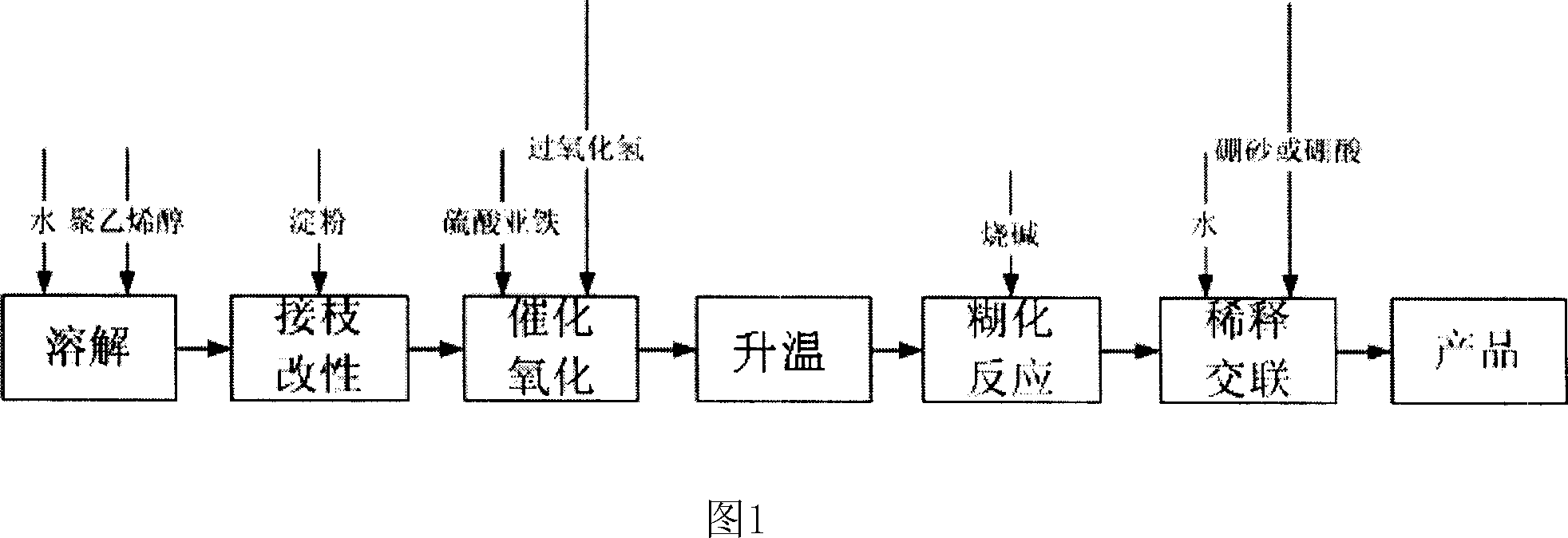

[0040]As shown in Figure 1, according to the proportion of raw materials, add 50% of the total water into the reactor, then add 1% polyvinyl alcohol, stir, heat up to 99°C to completely dissolve the polyvinyl alcohol, cool down to 60°C, add 5% corn starch, stirred and kept for 1 hour for graft modification; after modification, the material was cooled to 35°C, 0.005% ferrous sulfate was added to the reaction kettle, stirred evenly, and then 0.3% hydrogen peroxide solution was added to catalyze Oxidation reaction 1h. After the catalytic oxidation reaction, raise the temperature to 40°C to decompose the excess or unreacted hydrogen peroxide; then slowly add 4% ...

Embodiment 2

[0042] Raw material ratio:

[0043] Raw material ratio (wt%) Raw material ratio (wt%)

[0044] Polyvinyl alcohol 2 10wt% hydrogen peroxide solution 0.6

[0045] Starch 7 5wt% borax or boric acid solution 5

[0046] Ferrous sulfate 0.01 10wt% caustic soda solution 8

[0047] water 77.399

[0048] Operation process:

[0049] As shown in Figure 1, according to the proportion of raw materials, add 50% of the total water into the reaction kettle, then add 2% polyvinyl alcohol, stir, heat up to 99°C to completely dissolve the polyvinyl alcohol, cool down to 60°C, add 7% corn starch, stirred and kept for 1 hour for graft modification; after modification, the material was cooled to 35°C, 0.01% ferrous sulfate was added to the reaction kettle, stirred evenly, and then 0.6% hydrogen peroxide solution was added to catalyze Oxidation reaction 1h. After the catalytic oxidation reaction, raise the temperature to 60°C to decompose the excess or unreacted hydrogen peroxide; then slowly ...

Embodiment 3

[0051] Raw material ratio:

[0052] Raw material ratio (wt%) Raw material ratio (wt%)

[0053] Polyvinyl alcohol 1.5 10wt% hydrogen peroxide solution 0.5

[0054] Starch 6 5wt% borax or boric acid solution 4

[0055] Ferrous sulfate 0.0075 10wt% caustic soda solution 6

[0056] water 81.9925

[0057] Operation process:

[0058] As shown in Figure 1, according to the proportion of raw materials, add 50% of the total water into the reaction kettle, then add 1.5% polyvinyl alcohol, stir, raise the temperature to 99°C to completely dissolve the polyvinyl alcohol, cool down to 60°C, add 6% corn starch, stirred and kept for 1 hour for graft modification; after modification, the material was cooled to 35°C, 0.0075% ferrous sulfate was added to the reaction kettle, stirred evenly, and then 0.5% hydrogen peroxide solution was added to catalyze Oxidation reaction 1h. After the catalytic oxidation reaction, raise the temperature to 60°C to decompose the excess or unreacted hydrogen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com