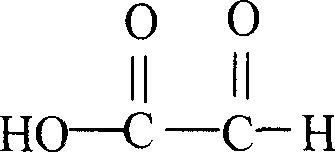

Method for preparing glyoxylate

A technology of glyoxylic acid and glyoxal, applied in the preparation of carboxylate, the preparation of organic compounds, chemical instruments and methods, etc., can solve the problems of low yield, easy environmental pollution, easy corrosion of equipment and cost, etc. The effect of stable quality, avoiding easy environmental pollution and improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

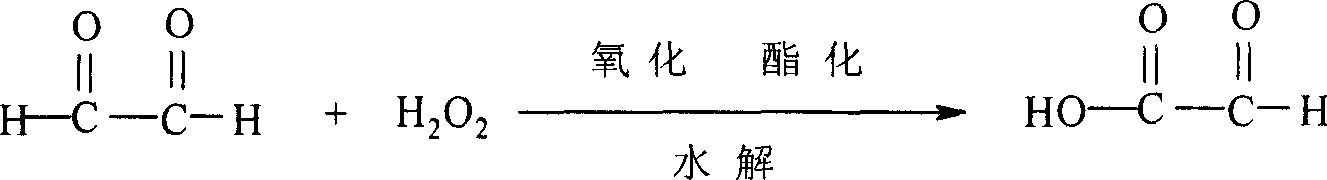

Method used

Image

Examples

Embodiment 1

[0023] Add 300ml (2.55mol) of 40% glyoxal solution into a 2500ml reactor equipped with a reflux condenser, stirrer, and thermometer, stir and cool, control the temperature at 5±2°C, and slowly drop 30% peroxide in 4 hours at the same time 290ml (2.55mol) of hydrogen solution, 260ml (0.255mol) of 14% ferrous sulfate solution and 100ml (0.65mol) of 10% ammonia solution, keep at 5±2°C for 4 hours, let stand overnight, filter the reaction solution to remove solid by-products 300ml of water-carrying agent toluene was added to the reaction mother liquor, heated to reflux, water removed, and water-carrying agent toluene was evaporated to obtain an oxidation product.

[0024] Add 100ml of concentrated sulfuric acid and 600ml of absolute ethanol to the oxidized product, perform esterification at 120°C for 2 hours, then distill under reduced pressure, collect at 0.01Mpa, 175°C to obtain the esterified product.

[0025] 100 ml of 16% sulfuric acid was added to the esterification product,...

Embodiment 2

[0027] Add 600ml (2.55mol) of 20% glyoxal solution into a 2500ml reactor equipped with a reflux condenser, stirrer, and thermometer, stir and cool, control the temperature at 6±2°C, and slowly drop 20% peroxide within 4 hours Hydrogen solution 435ml (2.55mol), 14% ferrous sulfate solution 260ml (0.255mol) and 20% ammonia solution 60ml (0.77mol), keep the controlled temperature reaction for 4 hours, stand overnight, the reaction solution is filtered to remove solid by-products, react Add 300ml of water-carrying agent toluene to the mother liquor, heat to reflux, remove water, distill out the water-carrying agent toluene, and obtain the oxidation product. Add 300ml of water-carrying agent toluene to the reaction solution, heat to reflux, remove water, and distill the water-carrying agent toluene to obtain the oxidation product.

[0028] Add 100ml of concentrated sulfuric acid and 600ml of absolute ethanol to the oxidation product, react at 120°C for 2 hours, then distill under r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com