Firming agent for surface layer of coal

A curing agent and surface technology, applied in chemical instruments and methods, other chemical processes, loading/unloading, etc., can solve problems such as physical health hazards, passenger health threats, time-consuming and labor-consuming, and achieve the effect of avoiding dust pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Raw material ratio:

[0028] Raw material name Proportion (wt%) Raw material name Proportion (wt%)

[0029] Polyvinyl alcohol 0.5 Potassium permanganate solution (concentration is 1wt%) 0.4

[0030] Starch 4 Borax or boric acid solution (concentration is 5wt%) 2

[0031] Caustic soda solution (concentration is 10wt%) 4 water 99.1

[0032] Operation process:

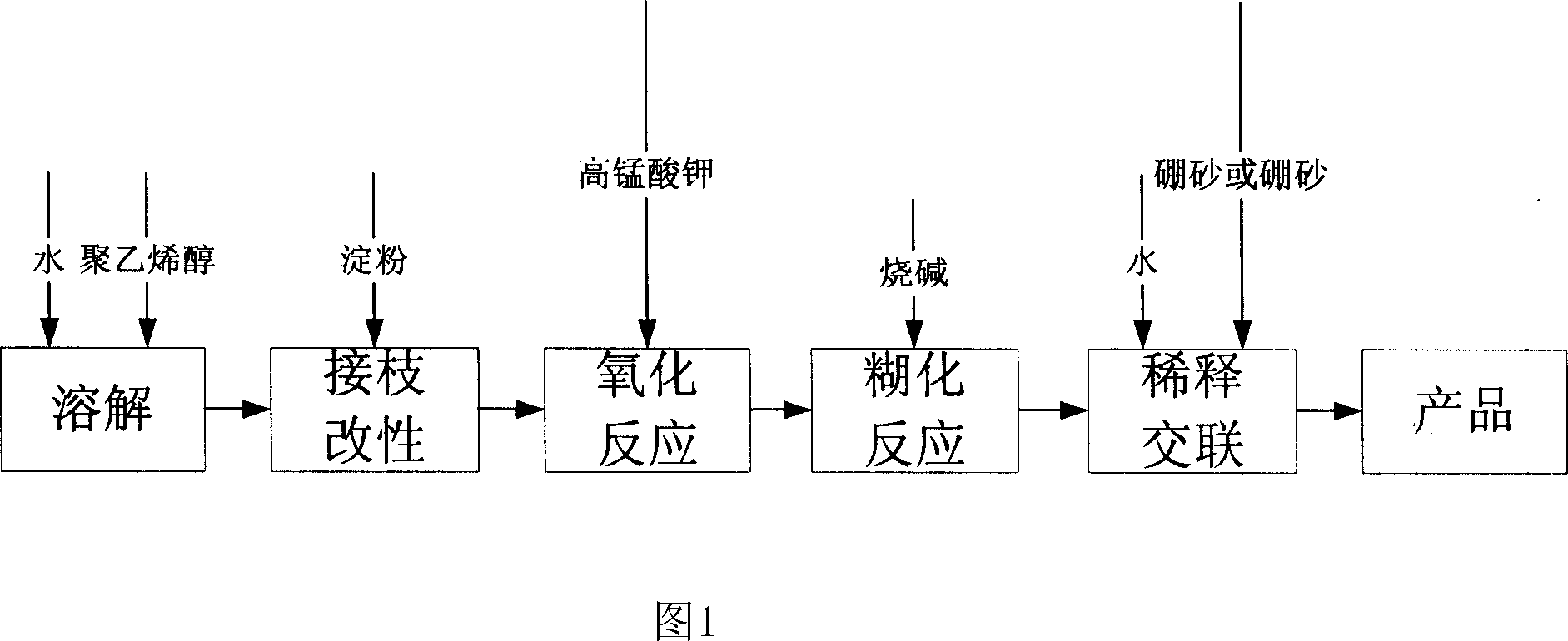

[0033] As shown in Figure 1, according to the proportion of raw materials, add 50% of the total water into the reaction kettle, then add 0.5% polyvinyl alcohol, stir, heat up to 99°C to completely dissolve the polyvinyl alcohol, cool down to 60°C, add 4% corn starch, stirred and kept warm for 1 hour to carry out graft modification; after modification, cool the material to 35°C, then add 0.3% potassium permanganate solution, oxidize for 1 hour, watch the color of the solution, it gradually changes from purple to colorless ; Then, under the condition of stirring, slowly add 4% caustic soda solution in the reactio...

Embodiment 2

[0035] Raw material ratio:

[0036] Raw material name Proportion (wt%) Raw material name Proportion (wt%)

[0037]Polyvinyl alcohol 1.5 Potassium permanganate solution (concentration is 1wt%) 0.6

[0038] Starch 6 Borax or boric acid solution (concentration is 5wt%) 5

[0039] Caustic soda solution (concentration is 10wt%) 8 water 78.9

[0040] Operation process:

[0041] As shown in Figure 1, according to the proportion of raw materials, add 50% of the total water into the reactor, then add 1.5% polyvinyl alcohol, stir, heat up to 99°C to completely dissolve the polyvinyl alcohol, cool down to 60°C, add Corn starch 6%, stirring and keeping warm for 1 hour for graft modification; after modification, cool the material to 35°C, then add 0.6% potassium permanganate solution, oxidize for 1 hour, watch the color of the solution, gradually change from purple to colorless ; Then, under the condition of stirring, slowly add 8% caustic soda solution in the reaction kettle, the mate...

Embodiment 3

[0043] Raw material ratio:

[0044] Raw material name Proportion (wt%) Raw material name Proportion (wt%)

[0045] Polyvinyl alcohol 1 Potassium permanganate solution (concentration is 1wt%) 0.4

[0046] Starch 5 Borax or boric acid solution (concentration is 5wt%) 3

[0047] Caustic soda solution (concentration is 10wt%) 6 water 84.6

[0048] Operation process:

[0049] As shown in Figure 1, according to the proportion of raw materials, add 50% of the total water into the reactor, then add 1% polyvinyl alcohol, stir, heat up to 99°C to completely dissolve the polyvinyl alcohol, cool down to 60°C, add 5% corn starch, stirring and keeping warm for 1 hour to carry out graft modification; after modification, cool the material to 35°C, then add 0.5% potassium permanganate solution, oxidize for 1 hour, watch the color of the solution, gradually change from purple to colorless Then, under stirring, slowly add 6% caustic soda solution in the reaction kettle, the material becomes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com