A high milk calcium granule and its producing technology

A technology of granule preparation and production process, which is applied in the field of high-milk calcium granule preparation and its production technology, can solve the problems of complex production and processing technology, high cost, and the inability of effective calcium nutrient absorption to achieve the best effect at the same time, so as to reduce production Costs and expenses, increased production efficiency, increased calcium absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

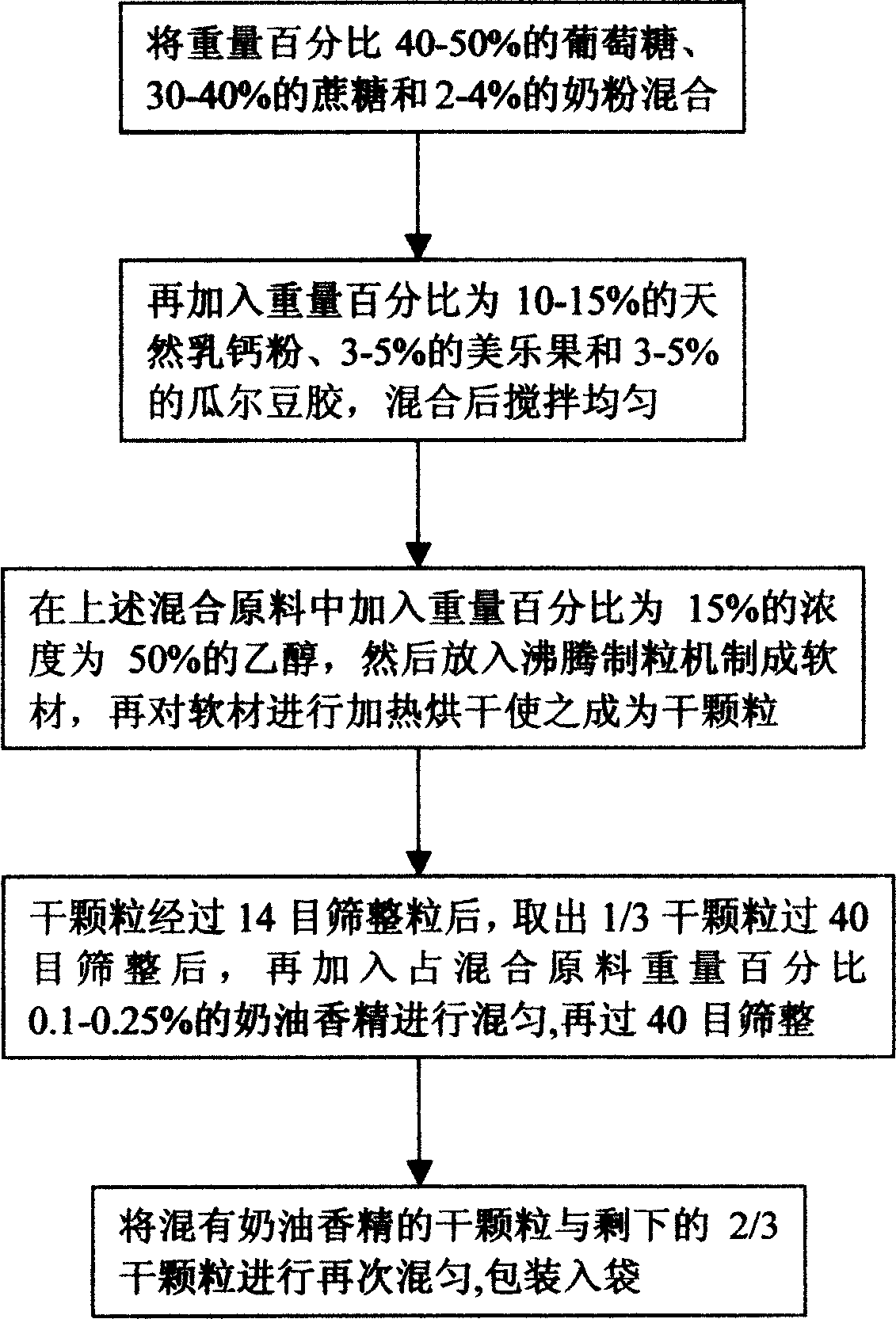

Method used

Image

Examples

Embodiment 1

[0013] Each bag of high milk calcium granules with a weight of 5 grams contains 0.56 grams of natural milk calcium powder, 2.18 grams of glucose, 0.2 grams of guar gum, 0.2 grams of merlot (FOS), and 1.685 grams of sucrose , 0.168 grams of milk powder and 0.007 grams of cream essence, brewed with 250 grams of hot water and melted immediately, the taste is mellow and rich in nutrition, and is widely welcomed by children and parents.

Embodiment 2

[0015] A production process of high-milk calcium granule granules. Before production, it is necessary to disinfect the production operation room, rinse the ground with a 1:2000 concentration of bromogeramine solution, and then use an ultraviolet lamp for 1 hour. During ultraviolet disinfection, every 15 cubic meters A 30-watt ultraviolet lamp tube is placed in 1 cm, and the lamp tube is 2 meters away from the ground. The temperature in the production operation room is 20 ° C, the relative humidity is 50%, and the cleanliness requirement reaches 100,000 grades. Then after mixing 45% glucose, 30% sucrose and 3% milk powder by weight, sieve through a 100-mesh sieve for later use, and then prepare 50% medicinal ethanol with a purity of 95% after adding water. Ethanol stock solution. The raw material mixed in the above-mentioned steps and percentage by weight are 12% natural milk calcium powder, 5% merlot (FOS) and 4.8% guar gum after mixing and putting into a horizontal trough mix...

Embodiment 3

[0017] A production process of high-milk calcium granule granules. Before production, it is necessary to disinfect the production operation room, rinse the ground with a 1:2000 concentration of bromogeramine solution, and then use an ultraviolet lamp for 1 hour. During ultraviolet disinfection, every 15 cubic meters A 30-watt ultraviolet lamp tube is placed in the center of the room. The lamp tube is 1.5 meters above the ground. The temperature in the production operation room is 25°C, the relative humidity is 45%, and the cleanliness requirement reaches 100,000 grades. The staff entering the operation room need to change clothes twice, soak their hands in 1:2000 bromogeramine solution for three minutes, then dry their hands with a dryer, and then put on sterilized work clothes to enter the operation room for operation. When making, after mixing 45% glucose, 35% sucrose and 2% milk powder by weight, sieve through a 100-mesh sieve for later use, and then add water to the medicin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com