A preparation method of debittered and discolored siraitia grosvenorii extracts

A technology of Luo Han Guo extract and Luo Han Guo, applied in the field of preparation of Luo Han Guo extract, to achieve the effects of no toxic side effects, increased content, and not easy to absorb moisture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

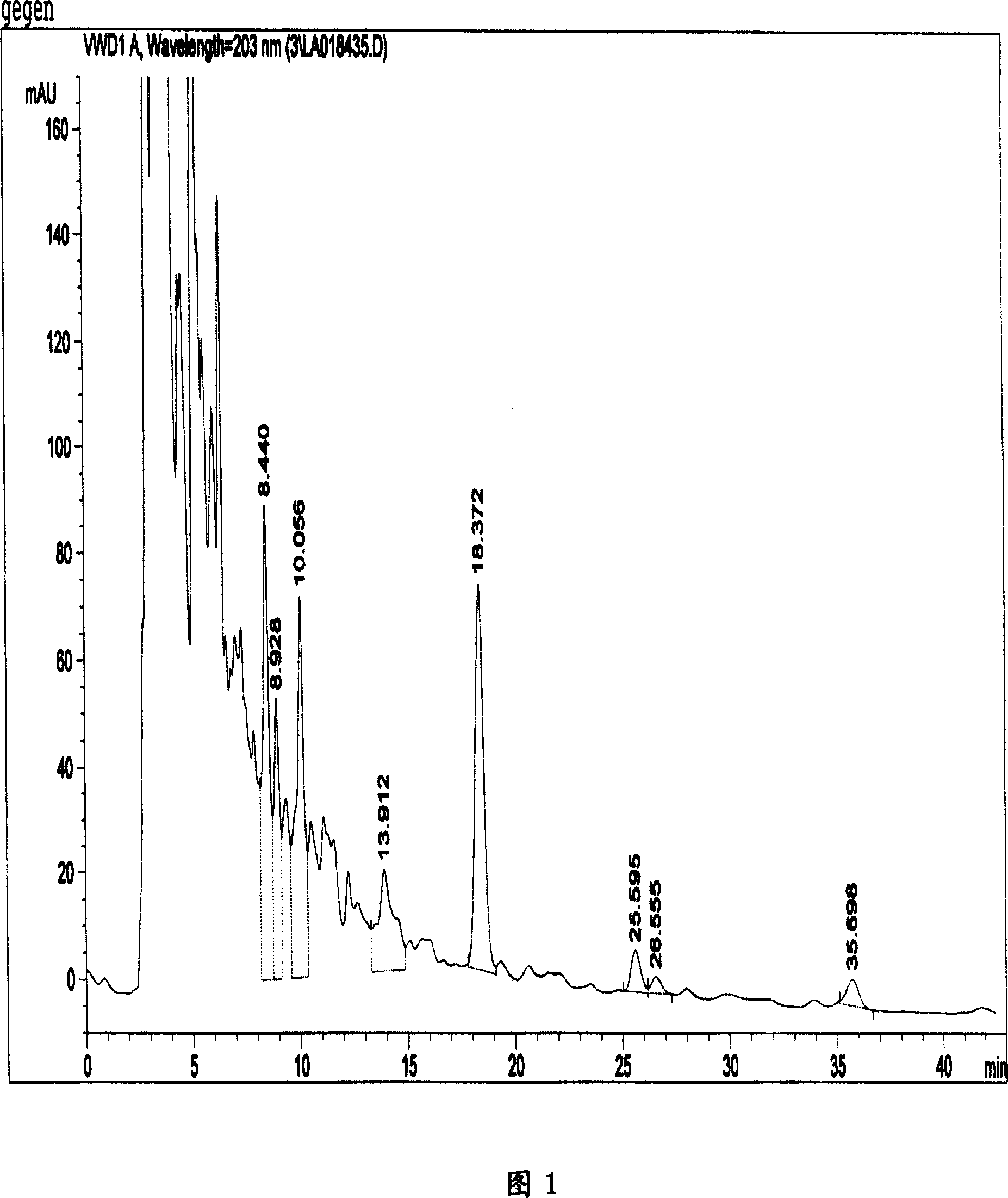

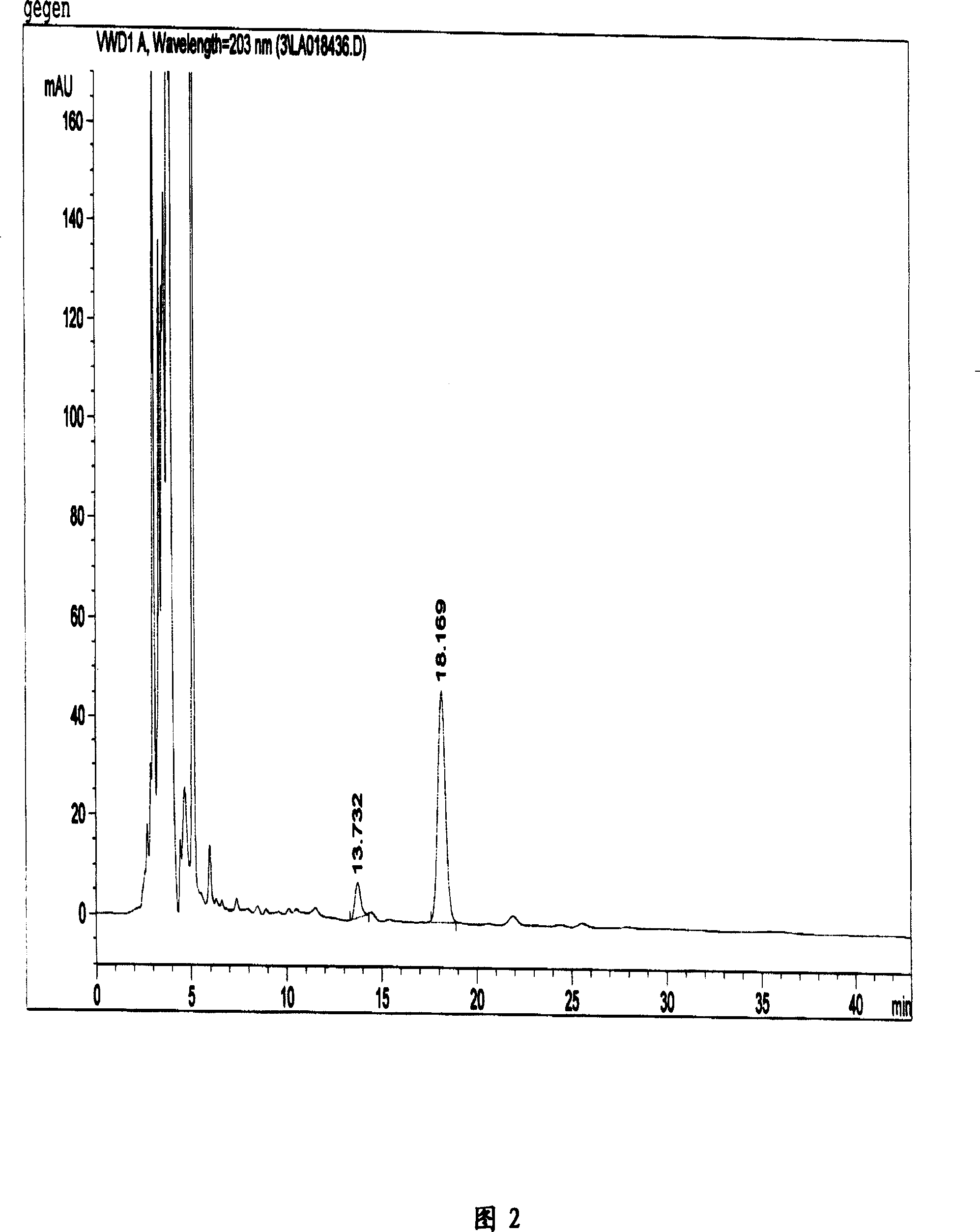

Image

Examples

Embodiment 1

[0022] 1) Soak and decoct Luo Han Guo in water 6 times its weight to obtain water extract A;

[0023] 2) Soak and decoct Luo Han Guo in water 8 times its weight to obtain water extract B;

[0024] 3) Merge and filter A and B;

[0025] 4) Concentrate the filtrate, and use D101 styrene copolymer macroporous adsorption resin to absorb the filtrate for decolorization;

[0026] 5) Wash the adsorbed decolorized resin until it is colorless, then elute it with an ethanol solution with a concentration of 75-80%, and collect the eluate;

[0027] 6) Concentrate the eluate, and use Al 2 o 3 The column adsorbs the eluent for deodorization;

[0028] 7) Filtrating, recovering the ethanol in the eluate, finally concentrating, spray-drying, and pulverizing to obtain decolorized and debittered Luo Han Guo extract.

Embodiment 2

[0030] 1) Soak and decoct Luo Han Guo in water 6 times its weight to obtain water extract A;

[0031] 2) Soak and decoct Luo Han Guo in water 8 times its weight to obtain water extract B;

[0032] 3) Merge and filter A and B;

[0033] 4) The filtrate is concentrated, and the filtrate is adsorbed with D201 styrene copolymer macroporous adsorption resin for decolorization;

[0034] 5) Wash the adsorbed decolorized resin until it is colorless, then elute it with an ethanol solution with a concentration of 75-80%, and collect the eluate;

[0035] 6) Concentrate the eluate, and absorb the eluent with a column filled with MgO for deodorization;

[0036] 7) Filtrating, recovering the ethanol in the eluate, finally concentrating, spray-drying, and pulverizing to obtain decolorized and debittered Luo Han Guo extract.

Embodiment 3

[0038] 1) Soak and decoct Luo Han Guo in water 6 times its weight to obtain water extract A;

[0039] 2) Soak and decoct Luo Han Guo in water 8 times its weight to obtain water extract B;

[0040] 3) Merge and filter A and B;

[0041] 4) The filtrate is concentrated, and the filtrate is adsorbed with D301 styrene copolymer macroporous adsorption resin for decolorization;

[0042] 5) Wash the adsorbed decolorized resin until it is colorless, then elute it with an ethanol solution with a concentration of 75-80%, and collect the eluate;

[0043] 6) Concentrate the eluate, and absorb the eluent with a column filled with activated carbon for deodorization;

[0044] 7) Filtrating, recovering the ethanol in the eluate, finally concentrating, spray-drying, and pulverizing to obtain decolorized and debittered Luo Han Guo extract.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com