Method for preparing ultra-fine copper powder from copper concentrate ore directly and ultrasonic membrane electrolysis

A technology for ultra-fine copper powder and copper concentrate, which is applied in the field of directly preparing ultra-fine copper powder from copper concentrate and the ultrasonic membrane electrolysis device used in it, to achieve the effects of shortening the processing flow, improving the physical and chemical properties, and shortening the flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

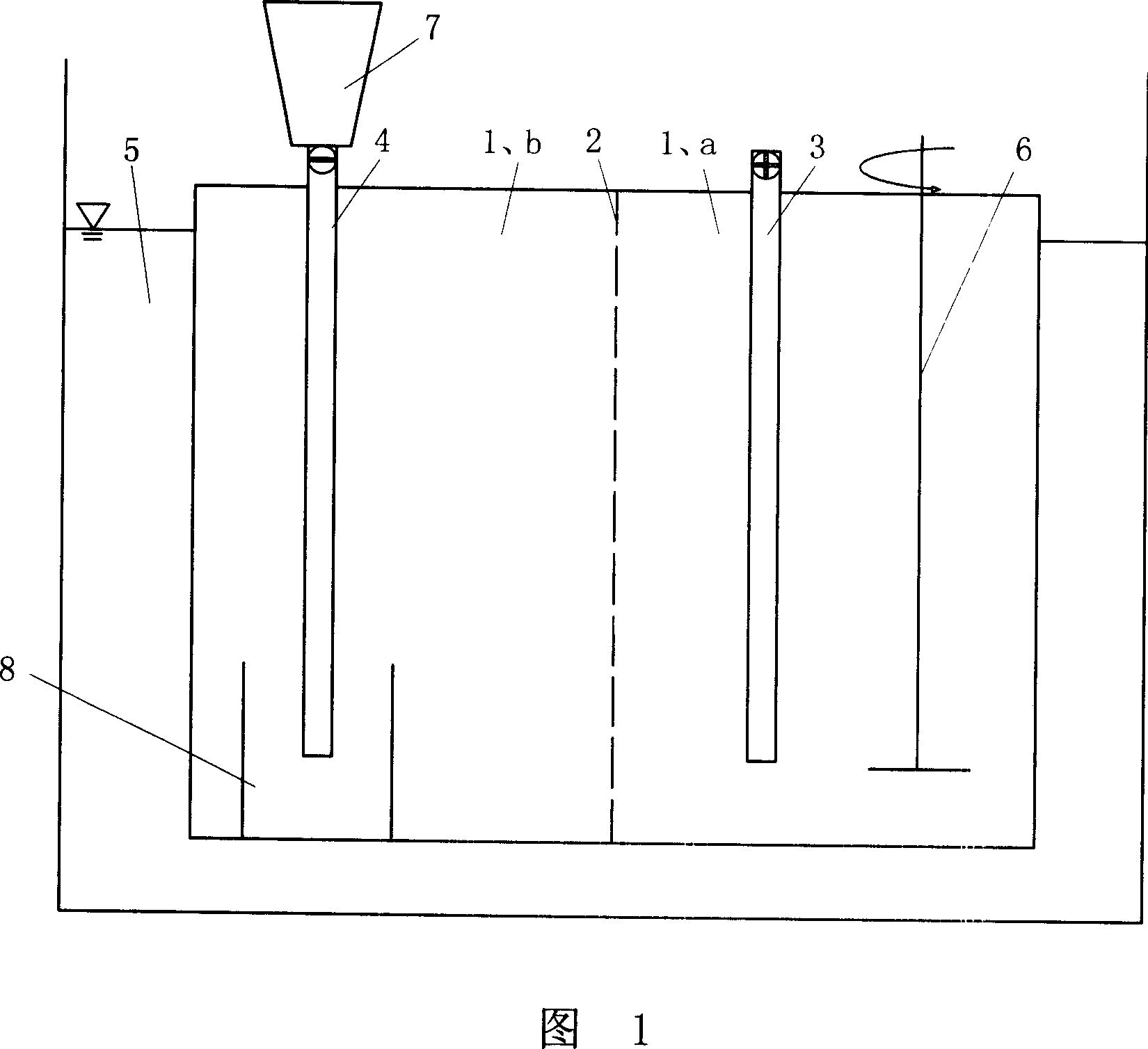

[0020] What shown in accompanying drawing 1 is ultrasonic membrane electrolysis device, comprises the membrane electrolyzer 1 that is made by glass fiber reinforced plastics or plexiglass, membrane electrolyzer 1 middle part is provided with diaphragm 2 and tank is divided into anode pool a and cathode pool b two parts, anode A graphite electrode 3 is provided in the pool a, a graphite electrode 4 is provided in the cathode pool b, and the diaphragm 2 is made of acid-resistant filter cloth through which the electrolyte can pass. This device has ultrasonic generator, agitator and ultrasonic oscillator 7, and ultrasonic generator and ultrasonic oscillator 7 are purchased from the market. The membrane electrolyzer rests in the medium tank 5 of the ultrasonic generator. The stirrer includes a motor deceleration mechanism and a stirring rod 6, which is driven by the motor deceleration mechanism to rotate the stirring rod 6, and the stirring rod 6 is inserted into the anode pool a o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com