Multiple-component filler matrix undercurrent wet land purifying and processing apparatus and undercurrent wet land purifying method

A purification treatment and subsurface flow wetland technology, applied in chemical instruments and methods, sustainable biological treatment, biological water/sewage treatment, etc., can solve the problems of decreased purification treatment effect, weakened aerobic microbial action, slow microbial recovery process in spring, etc. , to achieve the effect of not easily producing odor and mosquitoes, improving the effect of purification treatment, and increasing the effect of phosphorus removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

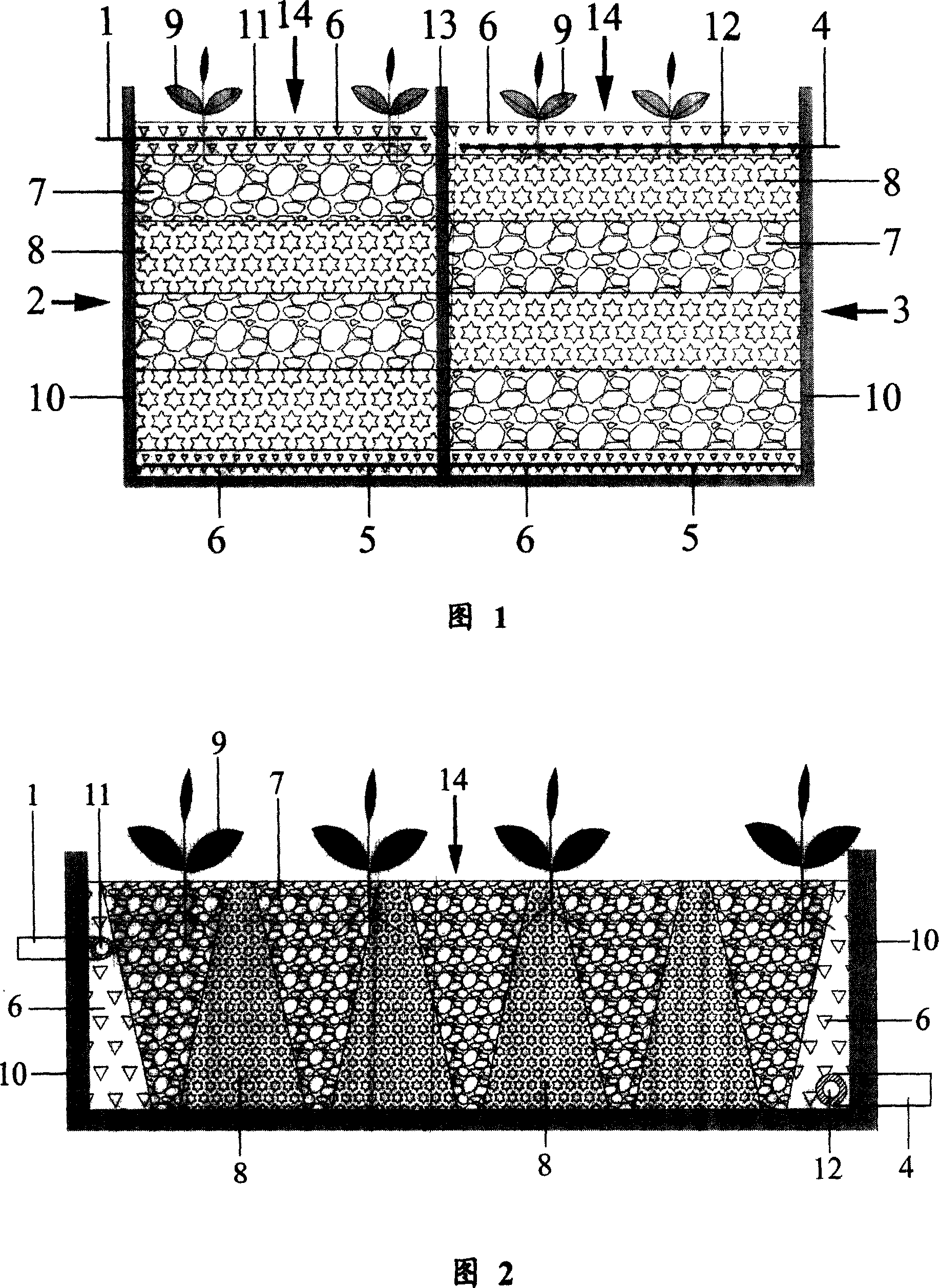

[0076] The wetland purification treatment pool (10) is in the shape of a cubic box as a whole, and the wetland purification treatment pool (10) is evenly filled with a filling matrix layer (14), and the pool wall of the wetland purification treatment pool (10) is higher than the upper surface of the filling matrix layer (14). On the surface, the upper end of the wetland purification treatment pool (10) is below the ground surface, and the water body always runs in the wetland purification treatment pool (10) under the ground surface.

[0077] Amphibious plants (9) are planted on the top of the filling matrix layer (14), the roots of the plants (9) are embedded in the filling matrix layer (14), the filling matrix layer (14) fixes the roots of the plants (9), and the filling matrix The layer (14) is a coarse particle size layer (6), a high-efficiency dephosphorization layer (7) and a medium particle size layer (8). Different permeability coefficients form a wave-like water flow ...

Embodiment 3

[0082] The cross-sectional area of the wetland purification treatment pool (10) is rectangular, trapezoidal, circular, semicircular, polygonal, or irregular polygonal, at least one of which is used, as shown in Figures 1 and 2.

[0083] Implement inverted 4

[0084] The filling matrix (14) filled in the wetland purification treatment tank (10) is a coarse-grained layer (6), a high-efficiency dephosphorization layer (7) and a medium-grained layer (8), and the coarse-grained layer (6) is gravel , gravel, ceramsite, volcanic basalt, large particle size, smooth surface, small water flow resistance, particle size 40-60mm, use at least one kind, porosity 35-45%, permeability coefficient 50-60cm / s , dry bulk density 1.6-1.8g / cm 3 , accounting for 5-20 of the total filler volume, as shown in Figure 1 and Figure 2.

Embodiment 5

[0086] The medium particle size layer (8) is gravel, crushed stone, ceramsite, volcanic basalt, medium particle size, large specific surface area, easy to form microbial film, particle size is 20-40mm, at least one type is used, and the porosity is 45- 55%, permeability coefficient 20-40cm / s, dry bulk density 1.5-1.7g / cm 3 , accounting for 20-60 of the total filler volume, as shown in Figure 1 and Figure 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Permeability coefficient | aaaaa | aaaaa |

| Dry unit weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com