Multi-component coatings that include polyurea coating layers

A polyurea coating technology, applied in the field of multi-component coatings including polyurea coatings, can solve problems such as high viscosity and poor adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

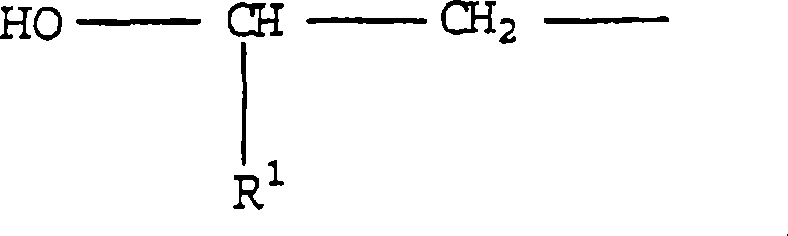

[0059] Amide functionality can be introduced into acrylic polymers by using suitable functional monomers in the preparation of the polymer, or by converting other functionalities into amide groups using techniques known to those skilled in the art. Likewise, other functional groups can be introduced as desired using (if available) suitable functionalizing monomers or necessary conversion reactions.

[0060] Acrylic polymers can be prepared by aqueous emulsion polymerization techniques and used directly in the preparation of aqueous coating compositions, or by organic solution polymerization techniques for solvent-borne compositions. When prepared via organic solution polymerization with groups capable of salt formation, such as acid or amine groups, the polymer can be dispersed in an aqueous medium after neutralization of these groups with base or acid. In general, any method known to those skilled in the art for preparing such polymers using recognized amounts of monomers may...

Embodiment

[0139] A polyurea composition was prepared from the formulation of Example 1 in Table 1 by mixing the Part A components to the Part B components in a 1:1 volume ratio in a high pressure impingement mixing apparatus manufactured by Gusmer Corporation.

[0140] The Part A ingredients were premixed and added to a storage chamber of the mixing device. Part B was prepared by mixing IPDI, terathane, butanediol, and neopentyl glycol to prepare a prepolymer under nitrogen atmosphere. A catalytic amount of dibutyltin dilaurate (DBTL) was added and the mixture was stirred for 15 minutes. The reaction mixture was heated first to 40°C and then to 100°C. The resulting prepolymer was cooled to 80° C., poured into 95% Desmodur N3400 and stirred for a further 15 minutes. Additional Desmodur N3400 was added to adjust isocyanate equivalent weight.

[0141] The calculated equivalent ratio of isocyanate to amine was 1.04.

[0142] Another polyurea composition was prepared from the formulation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com