Method of deeply purifying consumer waste infiltration liquid difficult degradation tail water by cement-based composite material

A composite material and domestic waste technology, applied in the field of wastewater treatment, can solve the problems of huge operation and maintenance costs, high pollutant concentration, blockage of membrane components, etc., to reduce construction costs, simple regeneration process, and less secondary pollutants. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Table 1 shows the water quality indicators of the leachate refractory tail water treated by the biological treatment unit of a tidal flat landfill in Shanghai.

[0024] Table 1 Leachate Tail Water Quality Index (mg / L)

[0025] Exterior

pH

COD Cr

TOC

TN

NH 3 -N

Ca 2+

Mg 2+

Cl -

SO 4 2-

brown yellow

transparent

8.14

518

172

511

155

30.2

240.8

4516

794

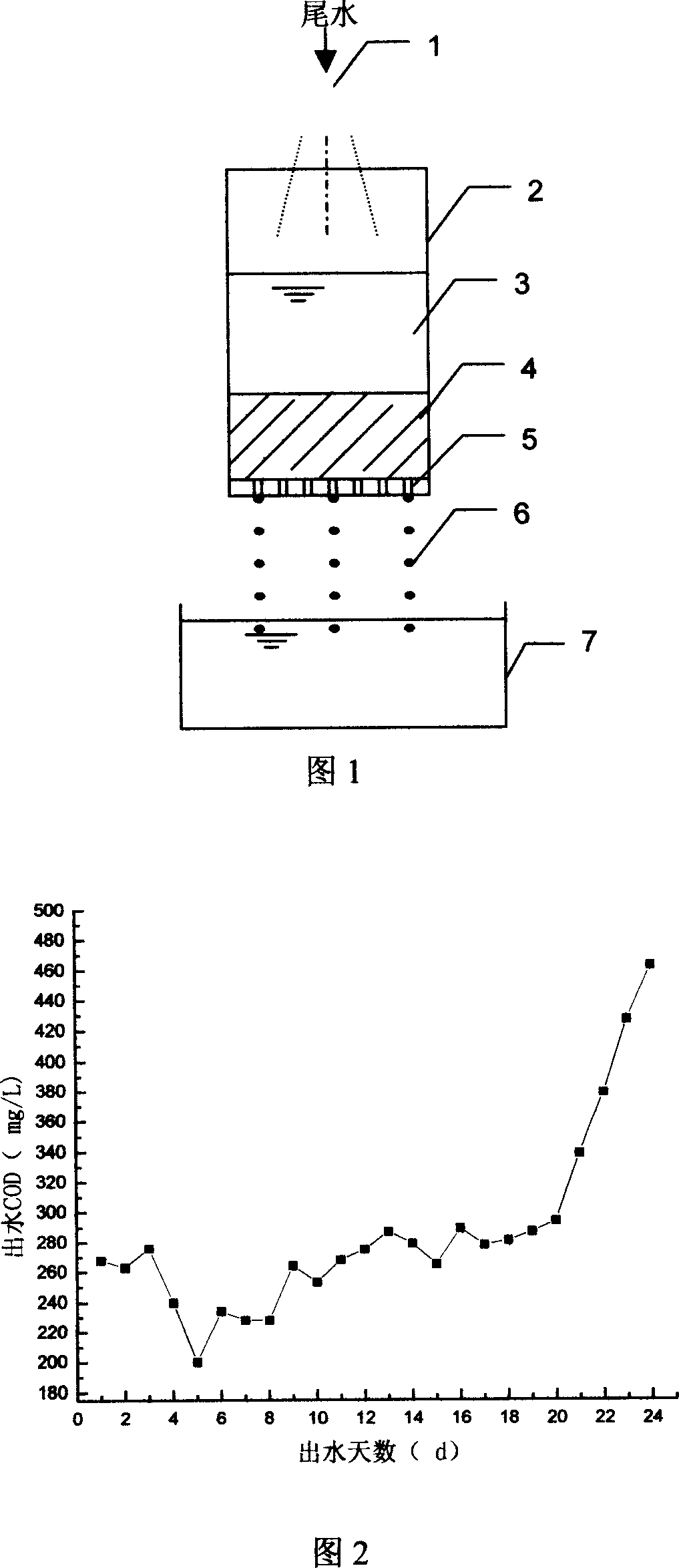

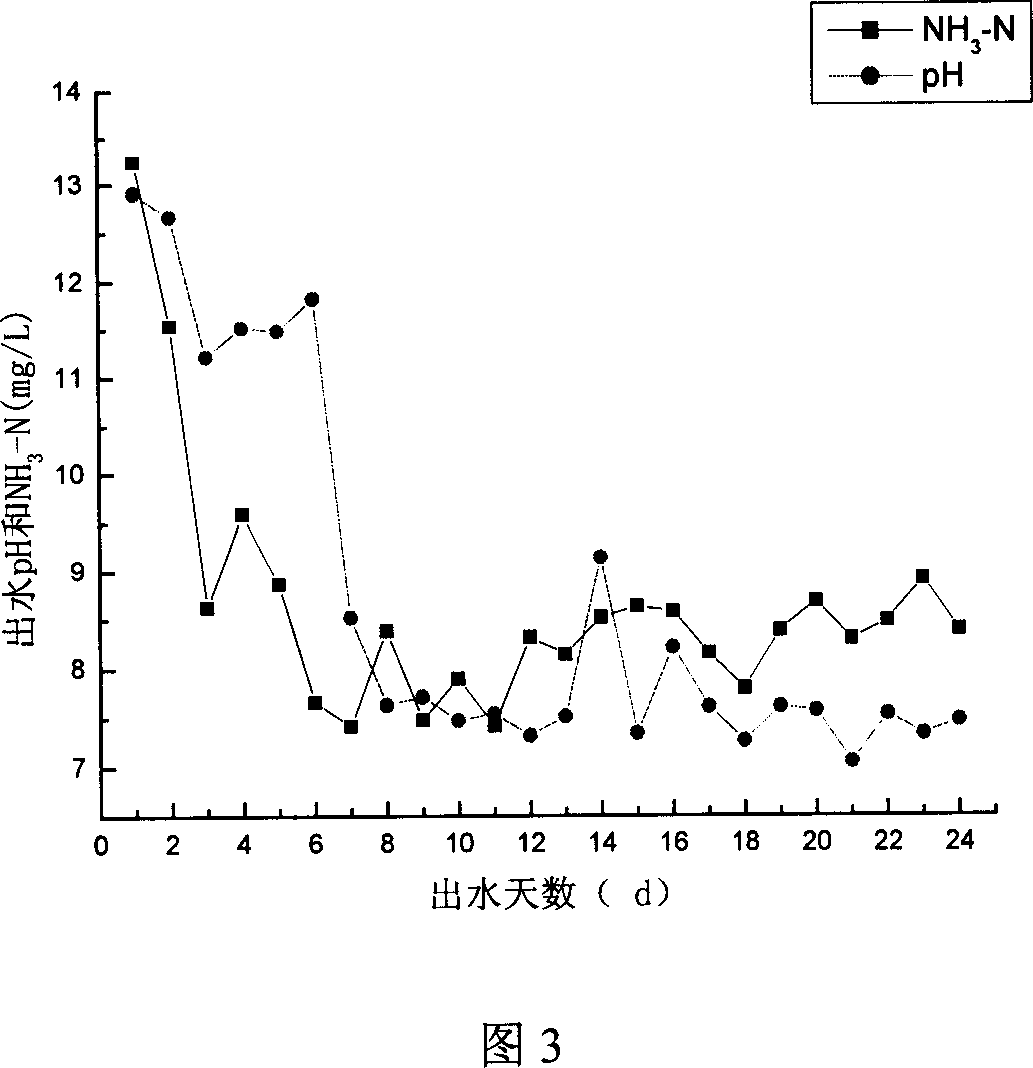

[0026] See Figures 1, 2, 3. First construct a permeable reaction layer in the laboratory: Weigh 60g of 425 # cement and 20 g of analytically pure CaCO 3 The powder is mixed evenly and filled into the PVC cylinder 2 above the bottom hole 5 with a diameter of 1 mm as shown in Figure 1 . The inner diameter of the PVC cylinder 2 is 5 cm, the thickness of the permeable reaction layer 4 formed after the reaction material is filled is 3.5 cm, and a height of 10 cm is left ...

Embodiment 2

[0029] Constructing a permeable reaction layer in the laboratory: Weigh 53.4 g of 425 # cement and 26.6 g of analytically pure CaCO 3The powder is mixed evenly and filled into the PVC cylinder 2 with small holes 5 (aperture 1mm) at the bottom in Fig. 1 . The inner diameter of the PVC column is 5 cm, and the thickness of the permeable reaction layer 4 formed after the reaction material is filled is 3.5 cm, and a height of 10 cm is left above the reaction layer 4 to contain the tail water column 3 . Add the leachate tail water described in Table 1 into the column evenly and intermittently through the water distributor 1 shown in Figure 1, and control the seepage water load to 0.6-0.8ml·g -1 d -1 , The seepage water 6 flows into the sump 7. The water quality of the effluent was similar to that of Example 1, except that the COD of the effluent began to rise sharply on the 19th day. In addition, the height of the water column required to maintain the permeate water load decreas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com