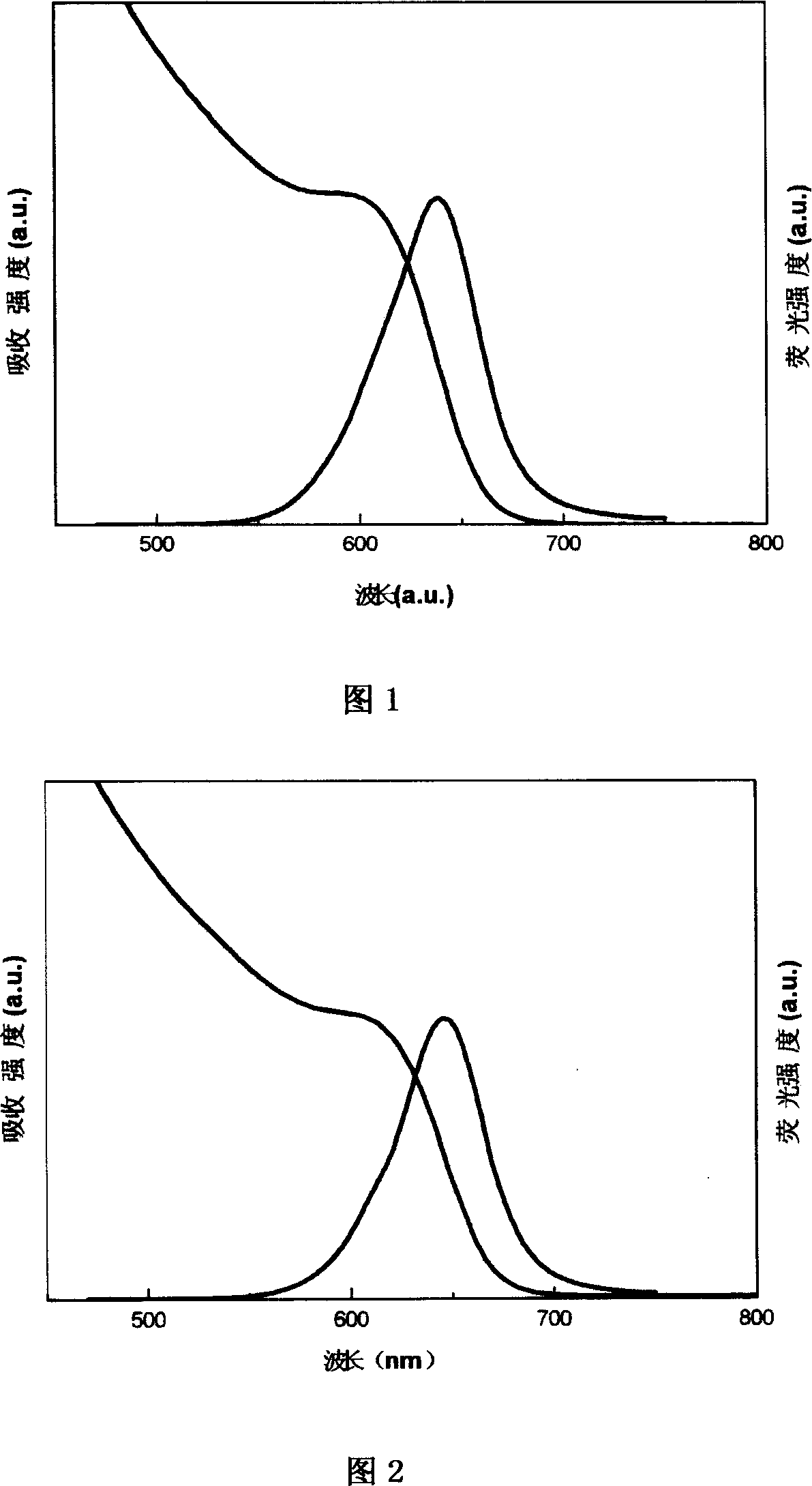

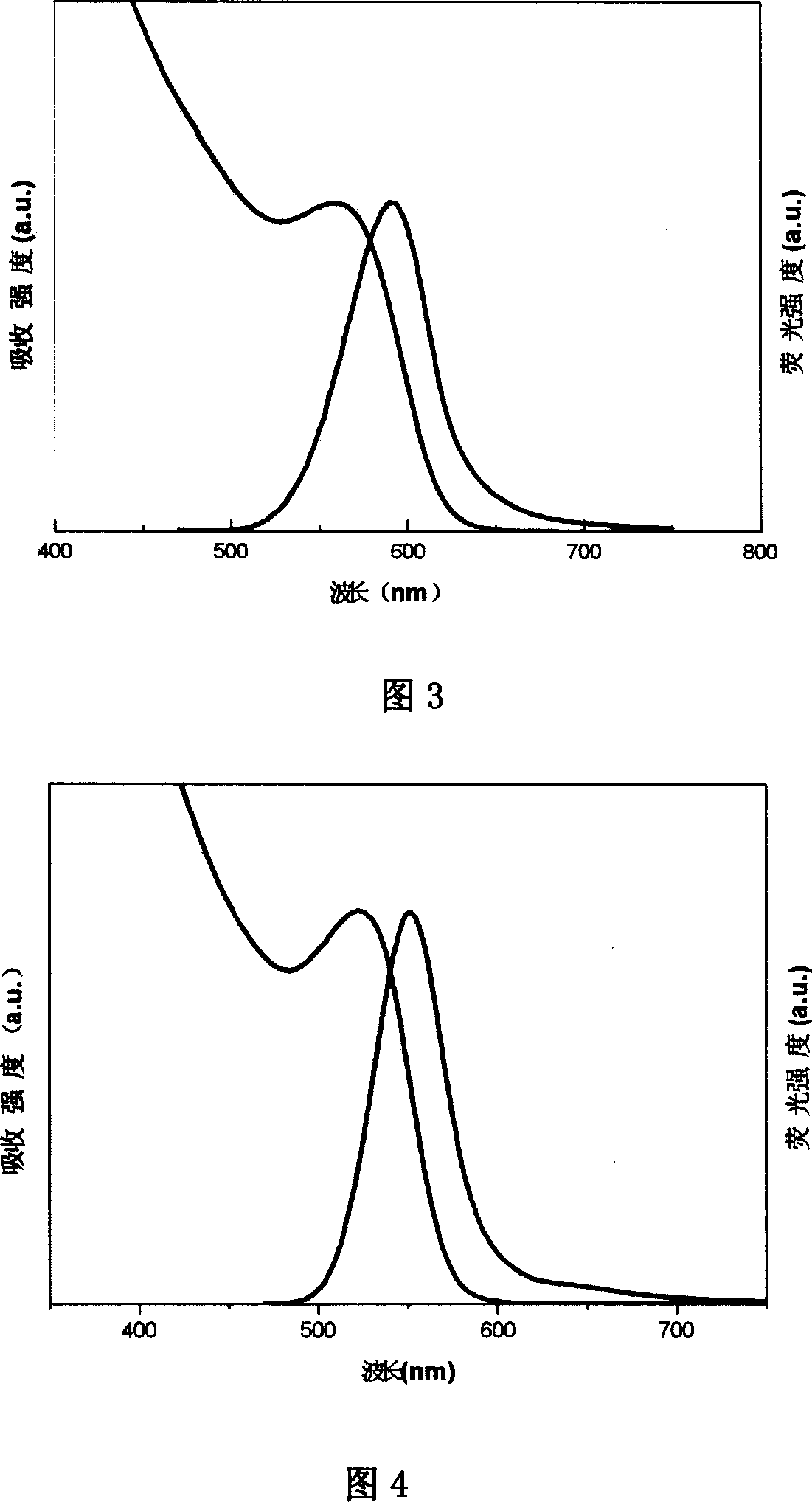

Hydrothermal preparation method for water-soluble CdTe quantum points

A water-soluble, quantum dot technology, applied in the field of nanotechnology preparation, can solve the problems of low fluorescence quantum efficiency and long reaction time, and achieve the effect of simple equipment and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] a. Synthetic sodium tellurium hydride solution: combine 40 mg of Te powder and 25 mg of sodium borohydride NaBH 4 Mix the powders, put them in a 10 ml sample bottle, add 1 ml of deionized water, and then place the reaction bottle at a temperature of 10°C for 8 hours to react to obtain a sodium telluride hydride solution;

[0022] b. Synthesize a mercaptoethylamine stable cadmium chloride solution: add 40 ml of deionized water to a three-necked flask, and then add 18 mg of cadmium chloride and 22 mg of mercaptoethylamine hydrochloride to obtain a Cd / MA molar ratio of 1 / 2.4 Cd-MA precursor solution, where [Cd] = 2 mmol / L;

[0023] c. Synthesis of CdTe precursor solution: Blow nitrogen into the above Cd-MA precursor solution for 30 minutes, add 125 microliters of the prepared sodium tellurium hydride solution, and stir for 10 minutes to obtain a CdTe precursor solution, where Cd / Te moles The ratio is 1 / 0.5, and the pH of the solution is adjusted to 5;

[0024] d. Preparation ...

Embodiment 2

[0026] a. Synthetic sodium tellurium hydride solution: combine 40 mg of Te powder and 25 mg of sodium borohydride NaBH 4 Mix the powders, put them in a 10 ml sample bottle, add 1 ml of deionized water, and then place the reaction bottle at a temperature of 10°C for 8 hours to react to obtain a sodium telluride hydride solution;

[0027] b. Synthesis of mercaptoethylamine stabilized cadmium chloride solution: add 40 ml of deionized water to a three-necked flask, add 91 mg of cadmium chloride and 137 mg of mercaptoethylamine hydrochloride successively to obtain a Cd / MA molar ratio of 1 / 3 Cd-MA precursor solution, where [Cd] = 10 mmol / L;

[0028] c. Synthesis of CdTe precursor solution: Blow nitrogen into the above Cd-MA precursor solution for 30 minutes, add 250 microliters of the prepared sodium tellurium hydride solution, and stir for 10 minutes to obtain a CdTe precursor solution, where Cd / Te mol The ratio is 1 / 0.2, and the pH of the solution is adjusted to 5;

[0029] d. Prepar...

Embodiment 3

[0031] a. Synthetic sodium tellurium hydride solution: combine 40 mg of Te powder and 25 mg of sodium borohydride NaBH 4 Mix the powders, put them in a 10 ml sample bottle, add 1 ml of deionized water, and then place the reaction bottle at a temperature of 10°C for 8 hours to react to obtain a sodium telluride hydride solution;

[0032] b. Synthesis of mercaptoethylamine stabilized cadmium chloride solution: add 40 ml of deionized water to a three-necked flask, and then add 110 mg of cadmium chloride and 164 mg of mercaptoethylamine hydrochloride to obtain a Cd / MA molar ratio of 1 / 3 Cd-MA precursor solution, where [Cd] = 12 mmol / L;

[0033] c. Synthesis of CdTe precursor solution: Blow nitrogen into the above Cd-MA precursor solution for 30 minutes, add 750 microliters of the prepared sodium tellurium hydride solution, and stir for 10 minutes to obtain a CdTe precursor solution, where Cd / Te mol The ratio is 1 / 0.5, and the pH of the solution is adjusted to 5.5;

[0034] d. Prepara...

PUM

| Property | Measurement | Unit |

|---|---|---|

| emission peak | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com