Magnesium-base massive non-crystalline material and preparing method thereof

An amorphous material and bulk technology, which is applied in the field of magnesium-based bulk amorphous material and its preparation, amorphous material and its preparation field, and can solve the problem that the corrosion resistance of magnesium-based amorphous material decreases, and the mechanical properties of magnesium-based amorphous material are reduced. performance degradation and other problems, to achieve the effect of improving corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

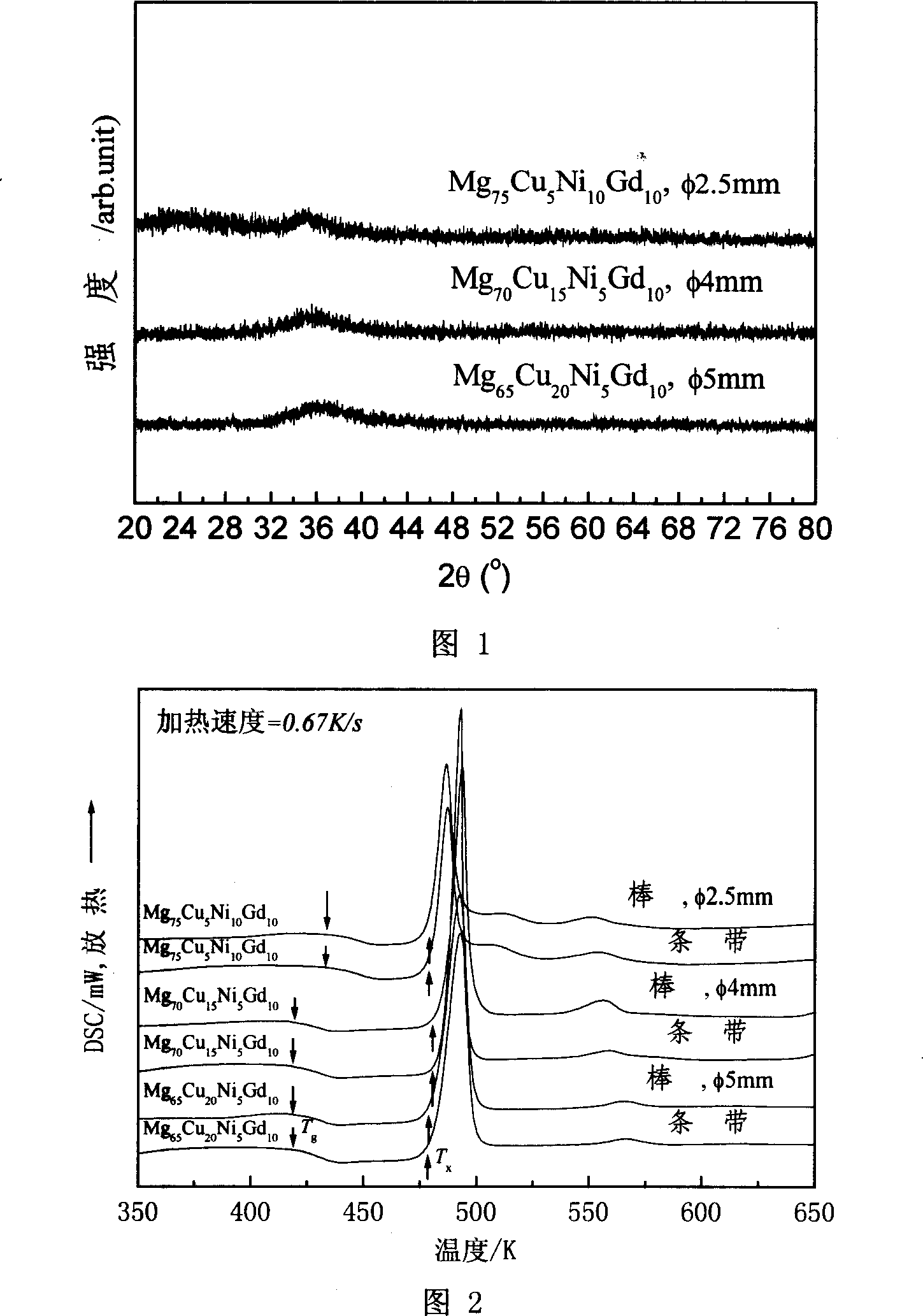

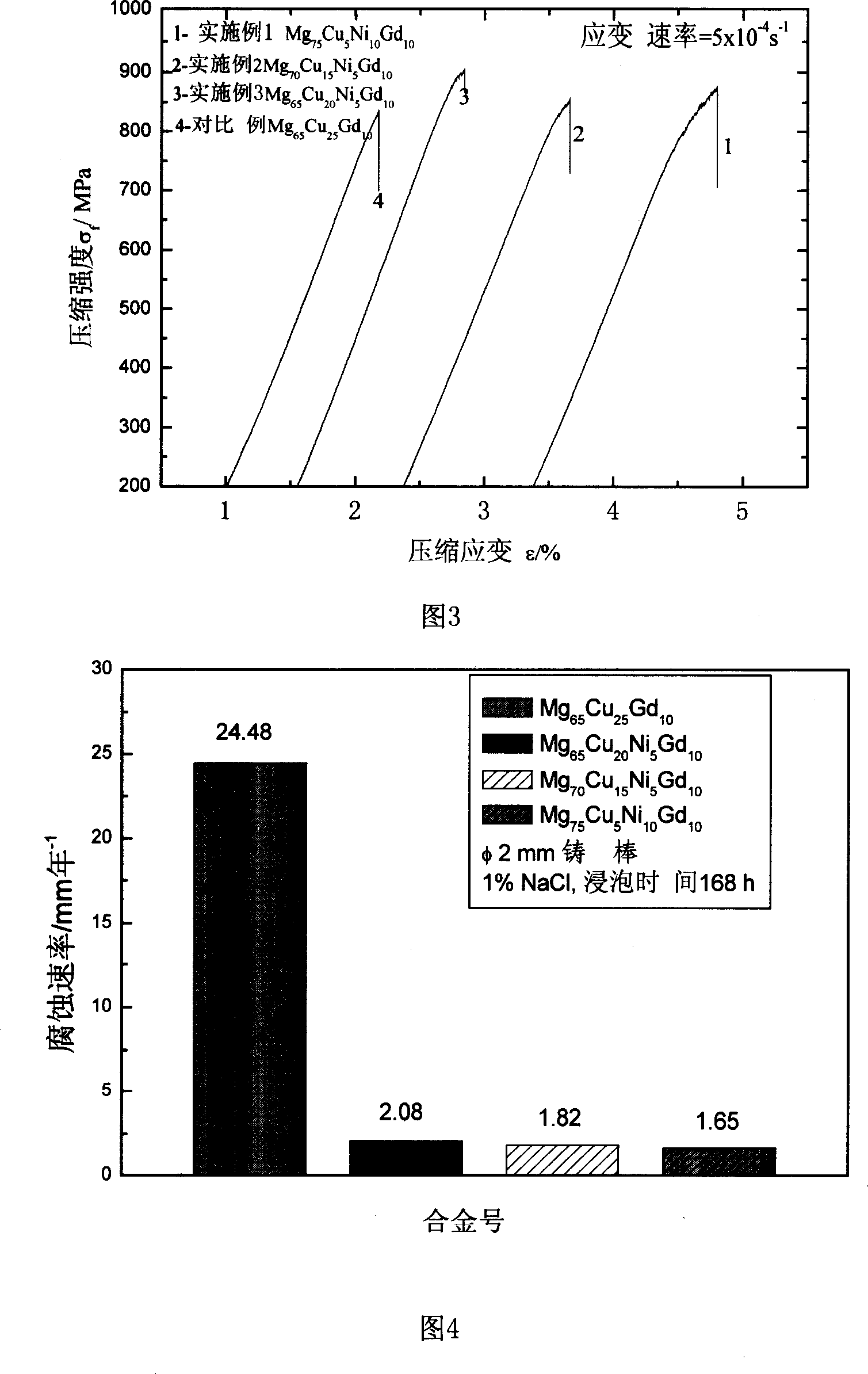

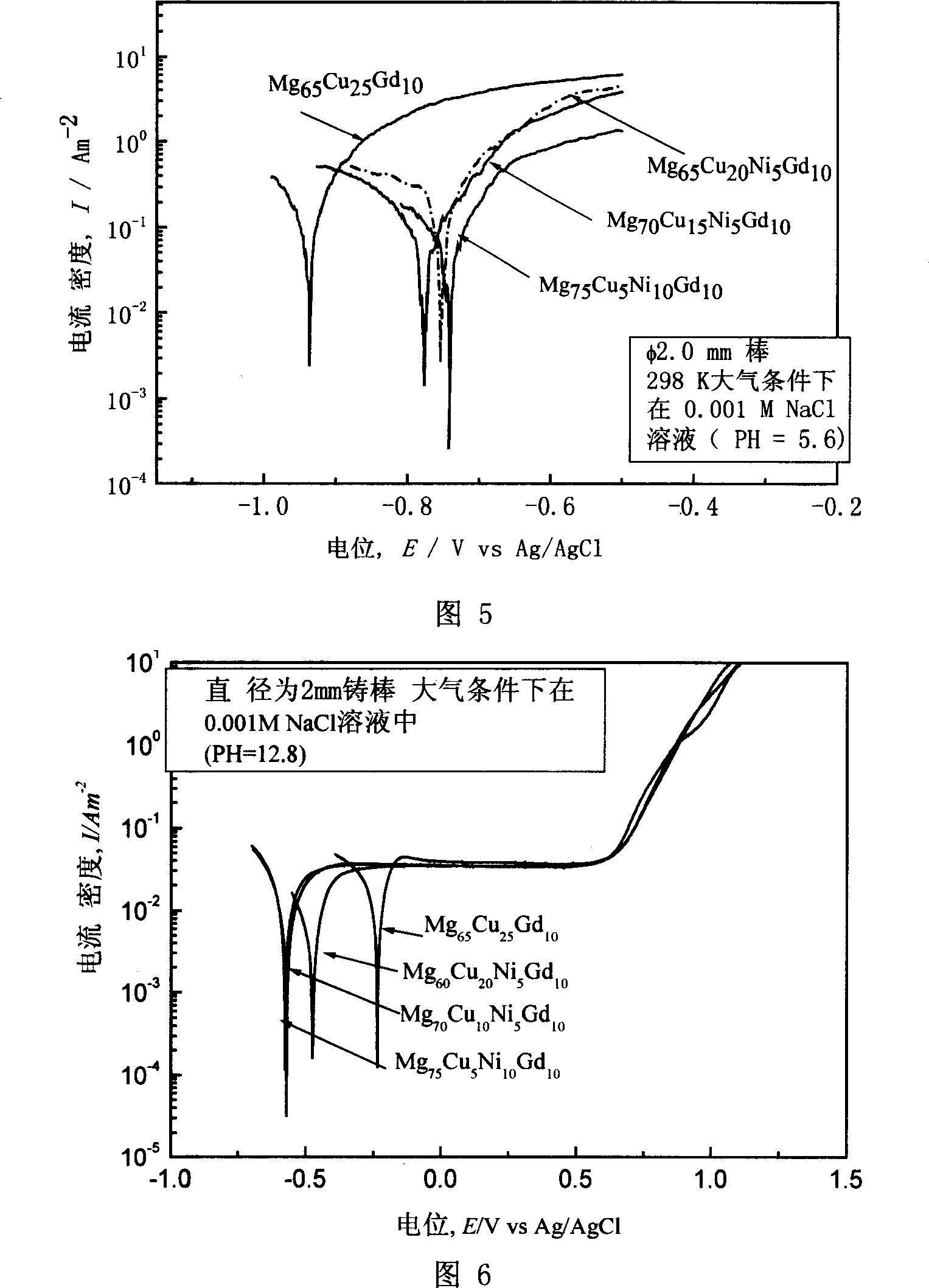

Embodiment 1

[0021] A magnesium-based bulk amorphous material contains components and their weight percentages: 42.4% magnesium, 7.4% copper, 13.7% nickel, and 36.5% gadolinium. The specific preparation method is as follows:

[0022] (1) Metal gadolinium is repeatedly smelted and purified four times in an electric arc furnace in an argon atmosphere adsorbed by titanium to remove impurities contained in rare earth metals to obtain metal gadolinium with a purity of ≥99.95%;

[0023] (2) above-mentioned metal gadolinium, metal copper, metal nickel are batched by above-mentioned percentage by weight, then in the electric arc furnace with the argon atmosphere that the titanium of magnetic stirring device is adsorbed, repeatedly smelt four times until the alloy melts evenly, after cooling, obtain relatively low The nickel-copper-gadolinium ternary alloy casting ingot of melting point, then this alloy casting ingot is broken;

[0024] (3) Vacuum the high-frequency induction vacuum furnace (vacuum...

Embodiment 2

[0028] A magnesium-based bulk amorphous material contains components and their weight percentages: 37.6% magnesium, 21.1% copper, 6.5% nickel, and 34.8% gadolinium. The specific preparation method is as follows:

[0029] (1) Metal gadolinium is repeatedly smelted and purified four times in an electric arc furnace in an argon atmosphere adsorbed by titanium to remove impurities contained in rare earth metals to obtain high-purity metal gadolinium with a purity of ≥99.95%;

[0030] (2) High-purity metal gadolinium, metal copper, and metal nickel are batched according to the above weight percentages, and then repeatedly smelted four times in an electric arc furnace with an argon atmosphere adsorbed by titanium with a magnetic stirring device until the alloy melts evenly, and after cooling, a relative Nickel-copper-gadolinium ternary alloy ingot with low melting point, and then the alloy ingot is broken;

[0031] (3) Vacuum the high-frequency induction vacuum furnace (vacuum degre...

Embodiment 3

[0035] A magnesium-based bulk amorphous material contains components and their weight percentages: 33.5% magnesium, 27.0% copper, 6.2% nickel, and 33.3% gadolinium. The specific preparation method is as follows:

[0036] (1) Metal gadolinium is repeatedly smelted and purified four times in an electric arc furnace in an argon atmosphere adsorbed by titanium to remove impurities contained in rare earth metals to obtain high-purity metal gadolinium with a purity of ≥99.95%;

[0037](2) High-purity metal gadolinium, metal copper, and metal nickel are batched according to the above weight percentages, and then repeatedly smelted four times in an electric arc furnace with an argon atmosphere adsorbed by titanium with a magnetic stirring device until the alloy melts evenly, and after cooling, a relative Nickel-copper-gadolinium ternary alloy ingot with low melting point, and then the alloy ingot is broken;

[0038] (3) Vacuum the high-frequency induction vacuum furnace (vacuum degree...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com