Prepn of high strength heat resistant aluminium alloy and its pipe

An aluminum alloy, heat-resistant technology, applied in the field of high-performance structural materials, to achieve the effects of improving heat resistance, reducing waste, and saving equipment power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

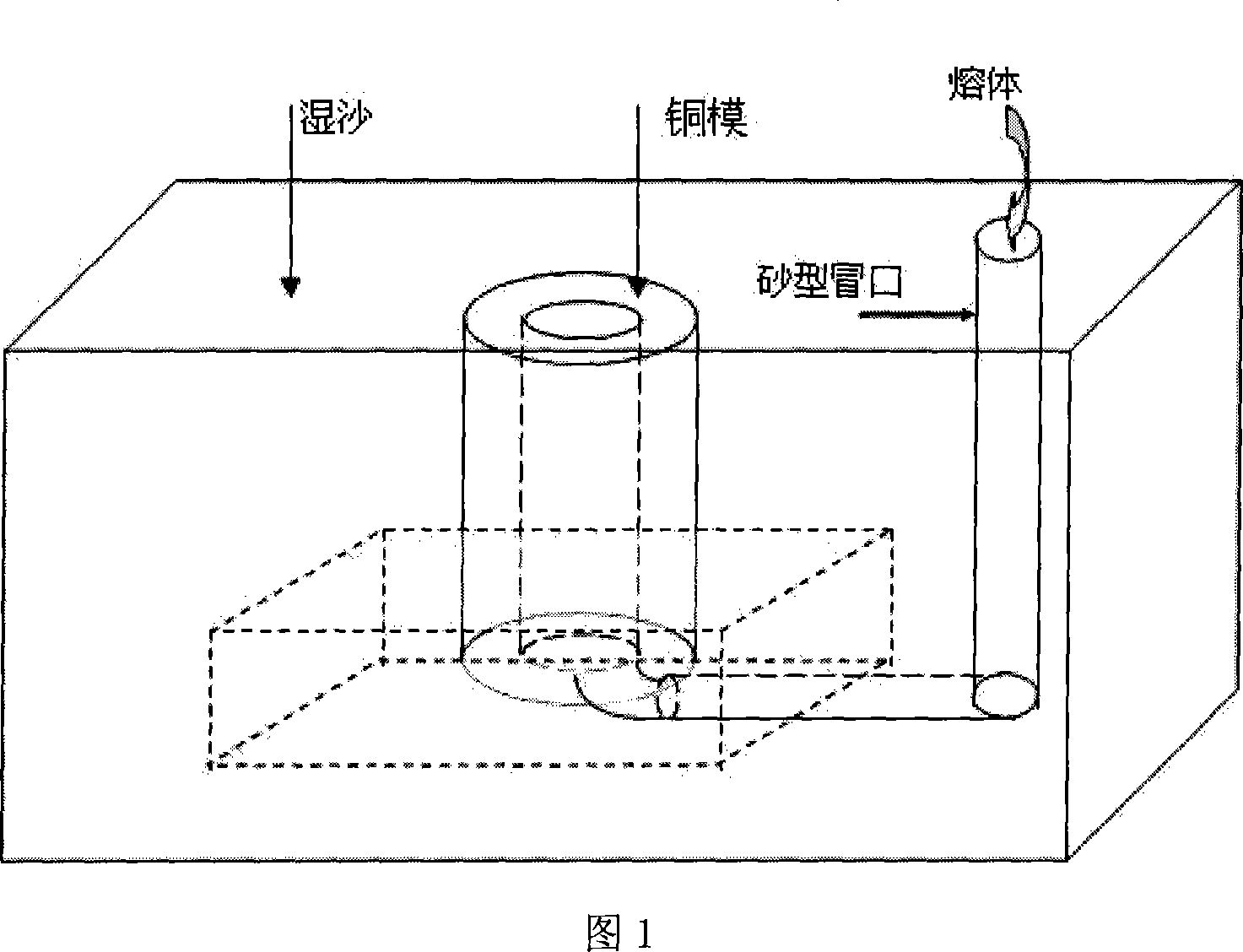

[0022] Alloy ingredients (raw materials: A00 pure aluminum, electrolytic copper, No. 2 industrial pure magnesium, 99.9% silver, electrolytic manganese, Cu-50Zr master alloy, Al-2.5Ti master alloy) are first put in the ZGG-0.025A vacuum melting furnace Melting, and then adopting the method of argon protection casting to make small-sized ingot alloys of φ80.5mm. The ingot alloy is machined to remove the head and tail, and then a certain number of small-sized ingot alloys are smelted in a flame coke furnace. The covering agent uses the configured sodium salt 2# flux (composition: 39% NaCl + 50% KCl + 6.6%Na 3 AlF 6 +4.4%CaF 6 ), the degasser is C 2 Cl 6 , after standing still and removing slag, in a copper mold buried in wet sand, a large-sized cylindrical ingot was poured in the form of reverse casting (Figure 1). After the alloy ingot was homogenized at 500°C for 12 hours, the surface was machining. The processed ingot is kept at 400°C for 5 hours, and the extrusion ratio...

Embodiment 2

[0024] Alloy ingredients (raw materials: AOO pure aluminum, electrolytic copper, No. 2 industrial pure magnesium, 99.9% silver, electrolytic manganese, Cu-50Zr master alloy, Al-2.5Ti master alloy) are first put in the ZGG-0.025A vacuum melting furnace Melting, and then adopting the method of argon protection casting to prepare a small-sized ingot alloy of φ80.5mm. The ingot alloy is machined to remove the head and tail, and then a certain number of small-sized ingot alloys are melted in a flame coke furnace. The covering agent is 2# flux of sodium salt, and the degassing agent is C 2 Cl 6 , after standing still and removing slag, in a copper mold buried in wet sand, a large-sized cylindrical ingot is poured in the form of reverse casting. After the alloy ingot is homogenized at 480°C for 18 hours, the surface is machined. The processed ingot is kept at 380°C for 5 hours, and the extrusion ratio is 6.5 on a 45 MN double-acting reverse extrusion machine. Through reverse hot ext...

Embodiment 3

[0026] Alloy ingredients (raw materials: A00 pure aluminum, electrolytic copper, No. 2 industrial pure magnesium, 99.9% silver, electrolytic manganese, Cu-50Zr master alloy, Al-2.5Ti master alloy) are first put in the ZGG-0.025A vacuum melting furnace Melting, and then adopting the method of argon protection casting to prepare a small-sized ingot alloy of φ80.5mm. The ingot alloy is machined to remove the head and tail, and then a certain number of small-sized ingot alloys are melted in a flame coke furnace. The covering agent is 2# flux of sodium salt, and the degassing agent is C 2 Cl 6, after standing still and removing slag, in a copper mold buried in wet sand, a large-sized cylindrical ingot is poured in the form of reverse casting. After the alloy ingot is homogenized at 490°C for 15 hours, the surface is machined. The processed ingot is kept at 410°C for 5 hours, and the extrusion ratio is 10 on a 45 MN double-acting reverse extrusion machine. Through reverse hot extru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com