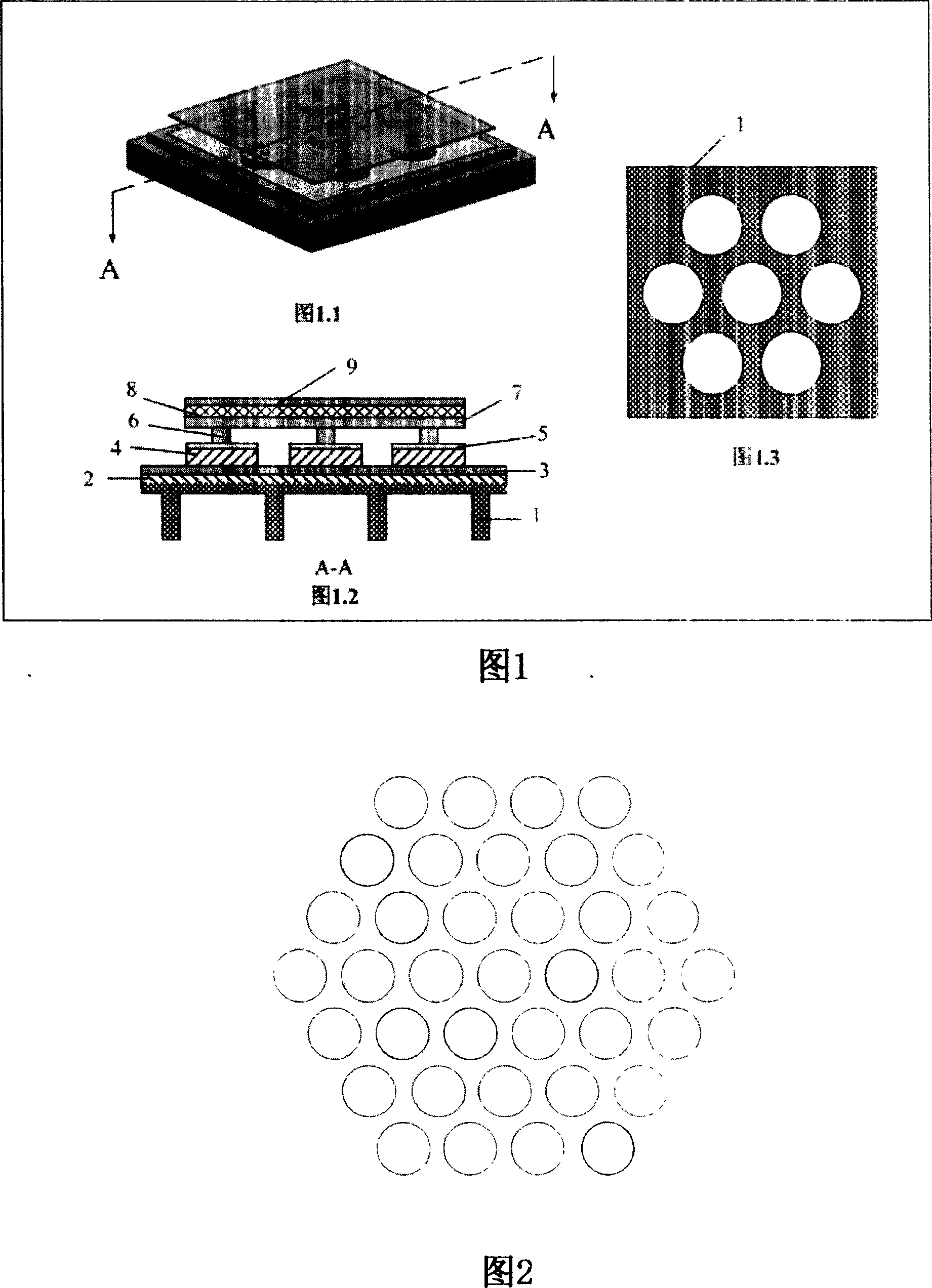

Piezoelectric thick diaphragm driving micro deformable mirror and producing method thereof

A micro-deformable mirror, thick film technology, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, piezoelectric/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, etc. It is not conducive to the decoupling control and optimal control of mirror shape, the decoupling algorithm is complex, and the equipment requirements are high. It is beneficial to commercial applications, avoiding complex decoupling control and overcoming high equipment requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

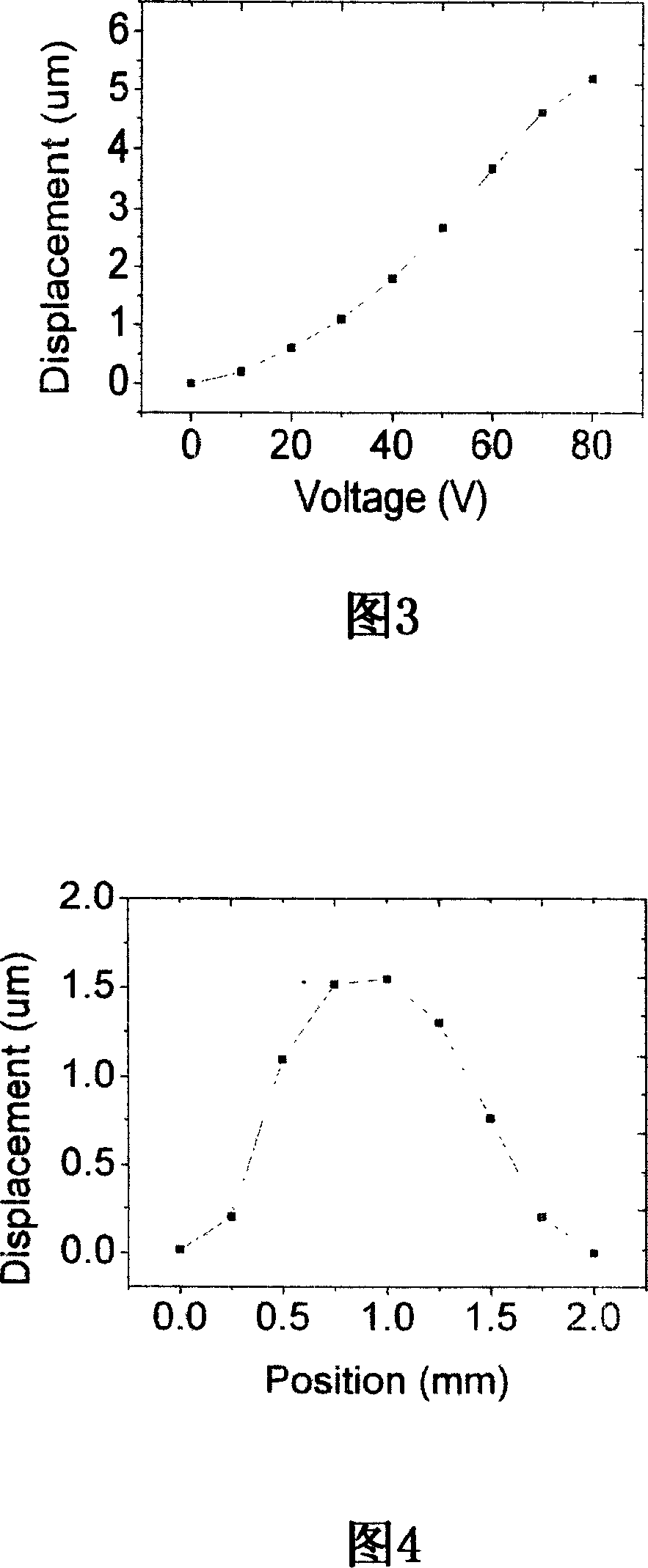

Examples

Embodiment 1

[0028] 1. Preparation of piezoelectric ceramic base film on silicon substrate

[0029] A one-component epoxy glue (ZKEP-4530, Beijing Bomi Company) with a viscosity of 120cps was prepared on the surface of the silicon substrate by a spin coating method (2000 rpm for 18 seconds, 4000 rpm for 30 seconds), and then the The piezoelectric ceramic substrate (diameter 25 mm, thickness 100 microns, Kunshan Jingfeng Electronics Co., Ltd.) is attached to the silicon substrate surface coated with epoxy glue, and a pressure of 0.5 MPa is applied on the piezoelectric ceramic substrate surface; then , put it in an oven at 160° C. for 1 hour to cure the epoxy glue, and prepare the silicon substrate piezoelectric ceramic base film.

[0030] 2. Preparation of piezoelectric ceramic thick film on silicon substrate

[0031] (1) Preparation of piezoelectric ceramic etching solution: first, NH 4 The saturated solution of F and the HF solution whose concentration is 49% are prepared BHF solution a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com