Method for catalyzing alcohol acid esterization by acidic ion liquid

A technology of acidic ionic liquid and catalyzed alkyd ester, which is applied in the direction of chemical instruments and methods, preparation of carboxylate, physical/chemical process catalyst, etc., can solve the problems of insufficient stability of repeated use, insufficient stability of water and air, etc., and achieve The effect of low vapor pressure, high conversion rate, and simplified separation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

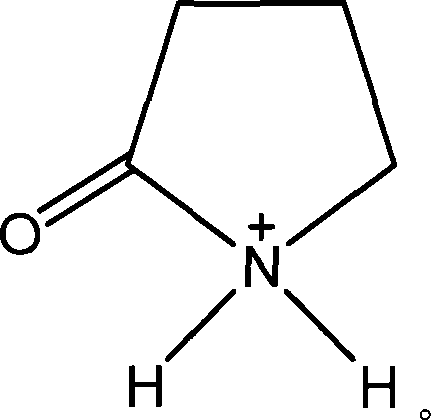

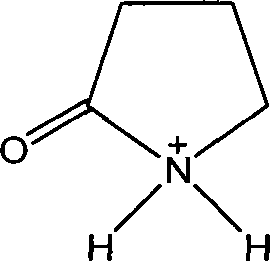

[0025] Example 1: Weigh 0.1 mol of acetic acid, 0.1 mol of ethanol, and 0.1 mol of ionic liquid α-pyrrolidone hydrogen sulfate; add the ionic liquid, ethanol, and acetic acid to a round bottom flask with a stirrer, a thermometer, and a reflux condenser. , Magnetic stirring, and heating and refluxing reaction at 80°C for 0.5 hours; standing for stratification, removing the upper esterification product, the conversion rate is 90.3%, the selectivity is 100%; the ionic liquid is repeatedly used after vacuum dehydration.

Embodiment 2

[0026] Example 2: Weigh 0.1 mol of acetic acid, 0.1 mol of n-butanol, and 0.02 mol of ionic liquid α-pyrrolidone nitrate; add the ionic liquid, n-butanol, and acetic acid to a circle with a stirrer, a thermometer, and a reflux condenser. It was placed in a bottom flask and reacted with magnetic stirring at 100°C for 1 hour; stood still for layering, and removed the upper esterified product, the conversion rate was 75..8%, the selectivity was 100%; the ionic liquid was vacuum dehydrated and reused.

Embodiment 3

[0027] Example 3: Weigh 0.1 mol of acetic acid, 0.1 mol of n-heptanol, and 0.01 mol of ionic liquid α-pyrrolidone hydrochloride; add the ionic liquid, n-heptanol, and acetic acid to a mixer with a stirrer, a thermometer, and a reflux condenser. In a round-bottom flask, magnetically stirred and reacted at 140°C for 2 hours; stand still for layering, and remove the upper esterification product, the conversion rate is 71.7%, the selectivity is 100%; the ionic liquid is vacuum dehydrated and reused.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com