Method for preparing mecillinam

A technology for the reaction of azemidine penicillin, which is applied in the field of preparation of azemidine penicillin, can solve problems such as harsh operating conditions, inconvenient production, unmentioned yield, etc., and achieve easy industrialization, good stability, and convenient process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

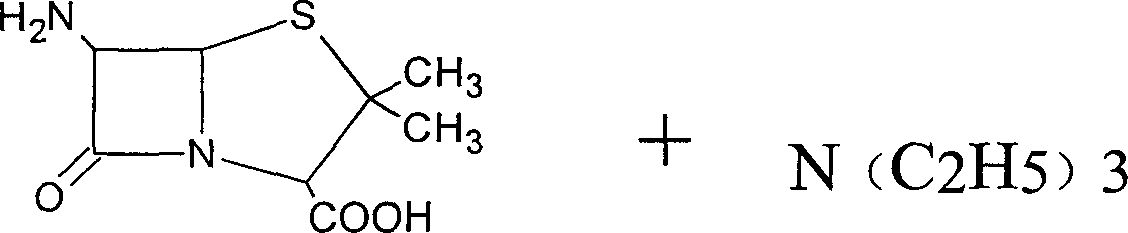

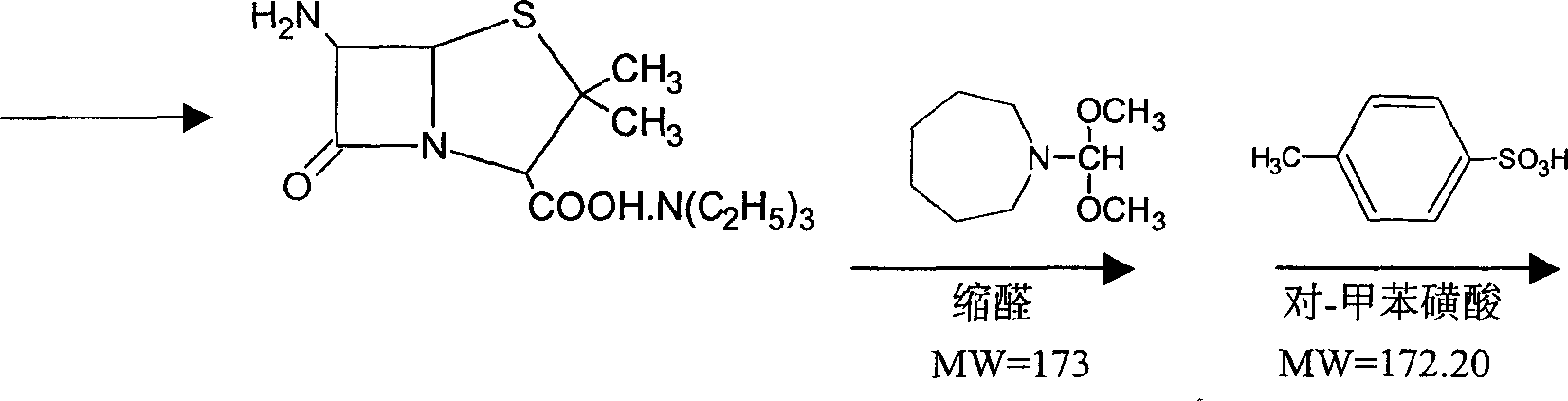

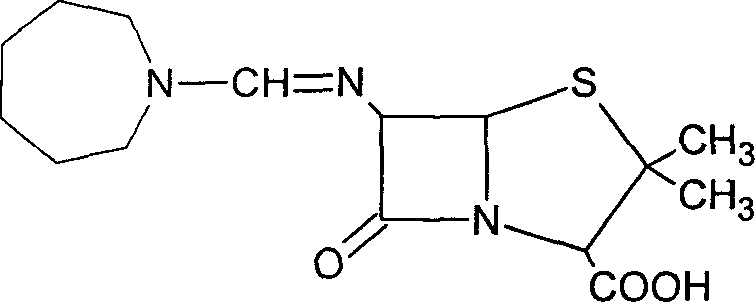

Method used

Image

Examples

Embodiment 1

[0032] Add 20g of 6-APA and 400ml of absolute ethanol to a 1000ml three-neck bottle equipped with a stirring and thermometer, cool to 5°C, slowly add 13.2g of triethylamine in 100ml of ethanol solution in about 30 minutes, and continue to stir until completely dissolved , still at 5°C, slowly add dropwise a 50ml ethanol solution containing 22g of acetal, after the addition, the temperature was raised to 10°C, and the reaction was continued with stirring for 4 hours. Use a rotary evaporator to control the temperature of the water bath below 30°C, concentrate under reduced pressure in vacuo until about 1 / 3 of the volume remains, add 2g of activated carbon to decolorize and stir at 5°C for 30 minutes, and filter. Wash with a small amount of absolute ethanol, combine and shake the filtrate washing liquid, measure and divide into two equal parts, each 26ml.

[0033] A. A portion of 26ml of feed liquid is cooled to 5°C, and it takes about 2 minutes to add 10g of p-toluenesulfonic ac...

Embodiment 2

[0036] Add 300ml of propanol and 20g of 6-APA to a 1000m three-neck bottle equipped with a stirring and thermometer, cool to 5°C, add dropwise 50ml of ethanol solution containing 9.5g of diethylamine in about 30 minutes, and maintain the internal temperature at 0°C , stir to fully dissolve. At 5°C, 22g of acetal in 50ml of ethanol was slowly added dropwise, and after the addition, the temperature was raised to 10°C, and stirring was continued for 5 hours.

[0037] Concentrate to about 1 / 3 of the residual volume as in Example 1, add 20ml of acetone and 2g of activated carbon, decolorize and stir at 2°C for half an hour, filter, wash with propanol, shake the lotion filtrate, and divide into two equal parts, each 37ml.

[0038] A. One portion of feed solution was cooled to 5°C, gradually added dropwise 10 g of p-toluenesulfonic acid in 30 ml of acetone solution with stirring for about 30 minutes, then stood still for 2 hours, filtered and dried to obtain 9.7 g of dry product. HP...

Embodiment 3

[0041] The feeding ratio and reaction device are the same as Example 1. After the reaction, concentrate to about 1 / 3 of the residual volume, add 2g of activated carbon for decolorization for 30 minutes, filter, wash the filter cake with 20ml of absolute ethanol, combine the lotion and stock solution, and shake well Divide into 2 parts, 31ml each.

[0042]A. A portion of feed solution at 10°C, after stirring, gradually add 10g of p-toluenesulfonic acid in 30ml of acetone solution dropwise, stop adding when crystallization appears, continue adding after stirring for 30 minutes, and finish adding dropwise in about 30 minutes. After the addition, it was left to stand at 5°C for 2 hours, filtered, washed with acetone, and dried under vacuum at room temperature to obtain 10.7 g of the product. HPLC 97.7%, moisture 0.47%, PH4.7 (10% aqueous solution), color grade < yellow No. 4, residual acetone 0.42%.

[0043] B. Another part of feed liquid was added dropwise to 10 g of p-toluenesu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com