Composite ceramic structure, method for producing same and wall structure using such composite ceramic structure

A technology of composite ceramics and structures, applied in ceramic products, other household utensils, botanical equipment and methods, etc., can solve the problems of bryophyte breeding, overflow of porous ceramic granules, etc., and achieve heat island effect prevention, light weight, and change The effect of easy work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

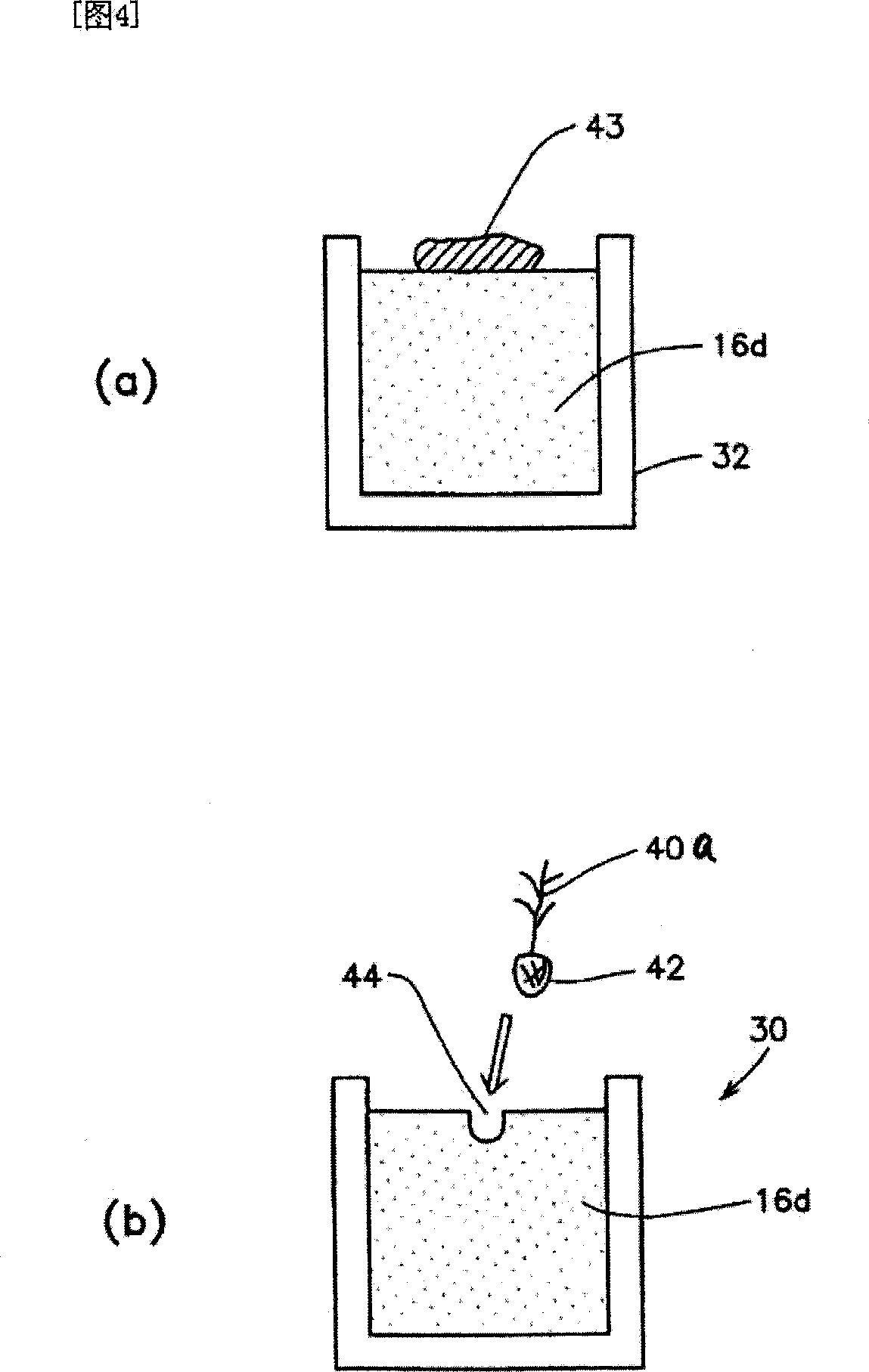

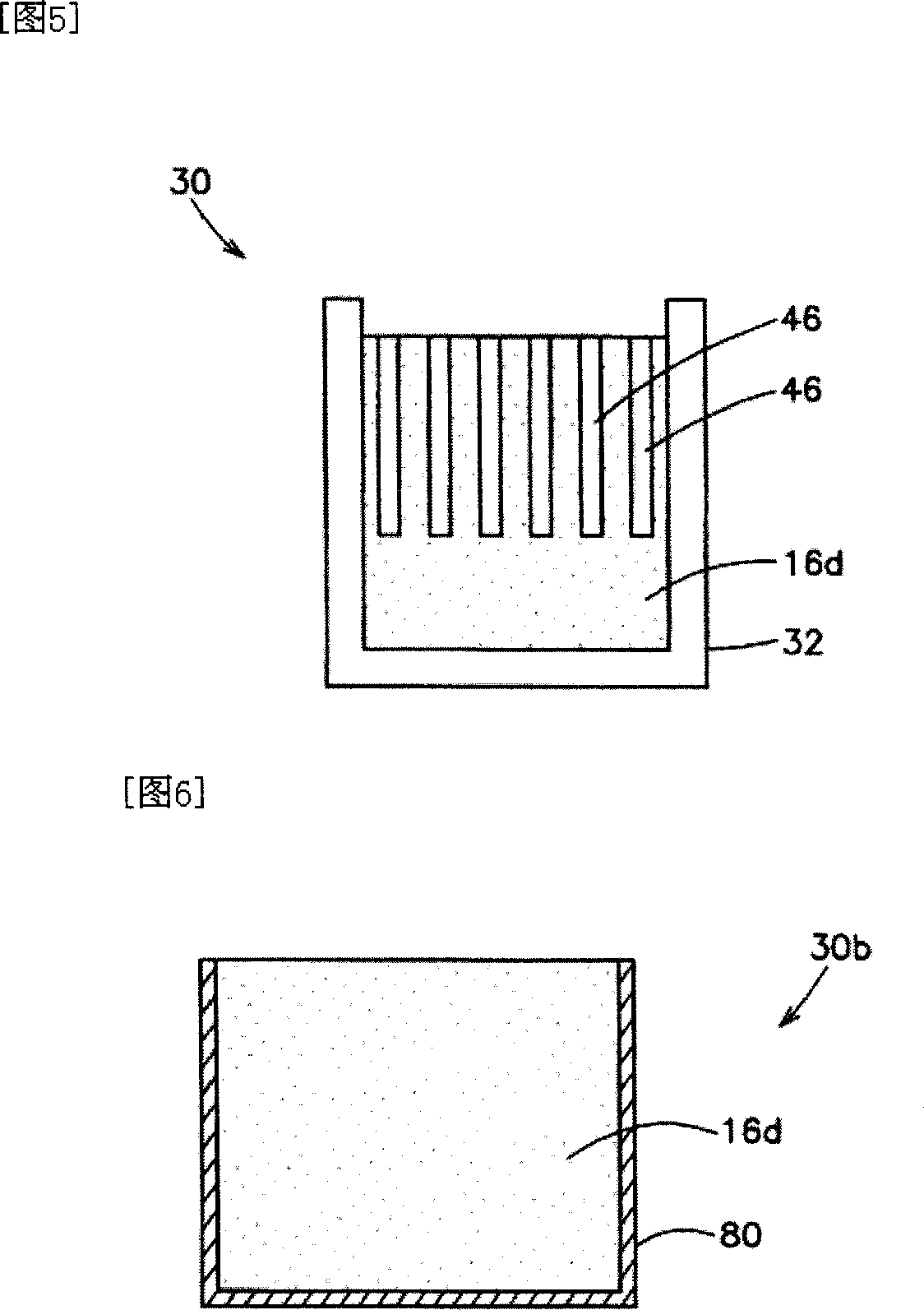

[0244] The clay was shaped into a flowerpot shape as shown in Figure 3, and bisque fired at 700°C to obtain a bisque-fired flowerpot. The outer diameter of the biscuit-fired flowerpot is 60cm in length, width and height respectively. The vertical, horizontal and high inner diameters are 55cm respectively. On the one hand, SiC (silicon carbide) is mixed into clay to get bad soil. The mixing rate of SiC (silicon carbide) was 5% by weight with respect to the dry weight of the clay. Fill this bad soil into biscuit pots. Fill the bad soil roughly up to a height of 5 cm from the top of the plain-fired flowerpot. The biscuit-fired flowerpot filled with bad soil was fired at 1000° C. for 24 hours to obtain a composite flowerpot filled with a porous ceramic body. Spread this flower pot over many roofs of 10-story buildings, each with plants and flowers. As a result, building air-conditioning energy costs can be reduced. Also, after more than one year, the surrounding area of th...

Embodiment 3

[0248] Urethane foam is used as an inflammable porous body, and the bad soil made of clay is slurried, and the urethane foam is impregnated to obtain a composite plain body of bad soil and urethane foam. The amount of mud attached is, for example, 0.3 g to a urethane foam of 1 cm×1 cm×1 cm. The shape of the urethane foam was the same as that of the porous ceramic body in the flower pot obtained in Example 1. Embed the composite plain body into the same bisque-fired flower pot used in Example 1, and fire both the same as in Example 1 to obtain a composite flower pot. This composite flower pot is covered with the roofs of many 10-storey buildings, each with plants and flowers. As a result, building air-conditioning energy costs can be reduced. Also, after more than one year, the surrounding area of the installation was not soiled, and the green environment was maintained. Water can be supplied by rainwater, requiring little effort to maintain and manage.

Embodiment 4

[0250] A porous body can be obtained by cutting out a rigid urethane resin having a porosity of 50% into a 30 cm square block. Leave this porous body and designate it as the upper side, and coat the other 5 sides with common oil-based paint to form a coating film with a thickness of about 0.5 mm to obtain a composite flower pot. Cover the roofs of many 10-storey buildings with this composite planting wood bowl, each with plants and flowers. As a result, building air-conditioning energy costs can be reduced. Also, after more than one year, the surrounding area of the installation was not dirty, and the green environment was maintained. Water can be supplied by rainwater, requiring little effort to maintain and manage.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com