Seed and seedholder combinations for high quality growth of large silicon carbide single crystals

A technology of silicon carbide and seed clips, applied in the field of sublimation growth, which can solve the problems of low surface step density per unit area, difficulty, less and more information, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

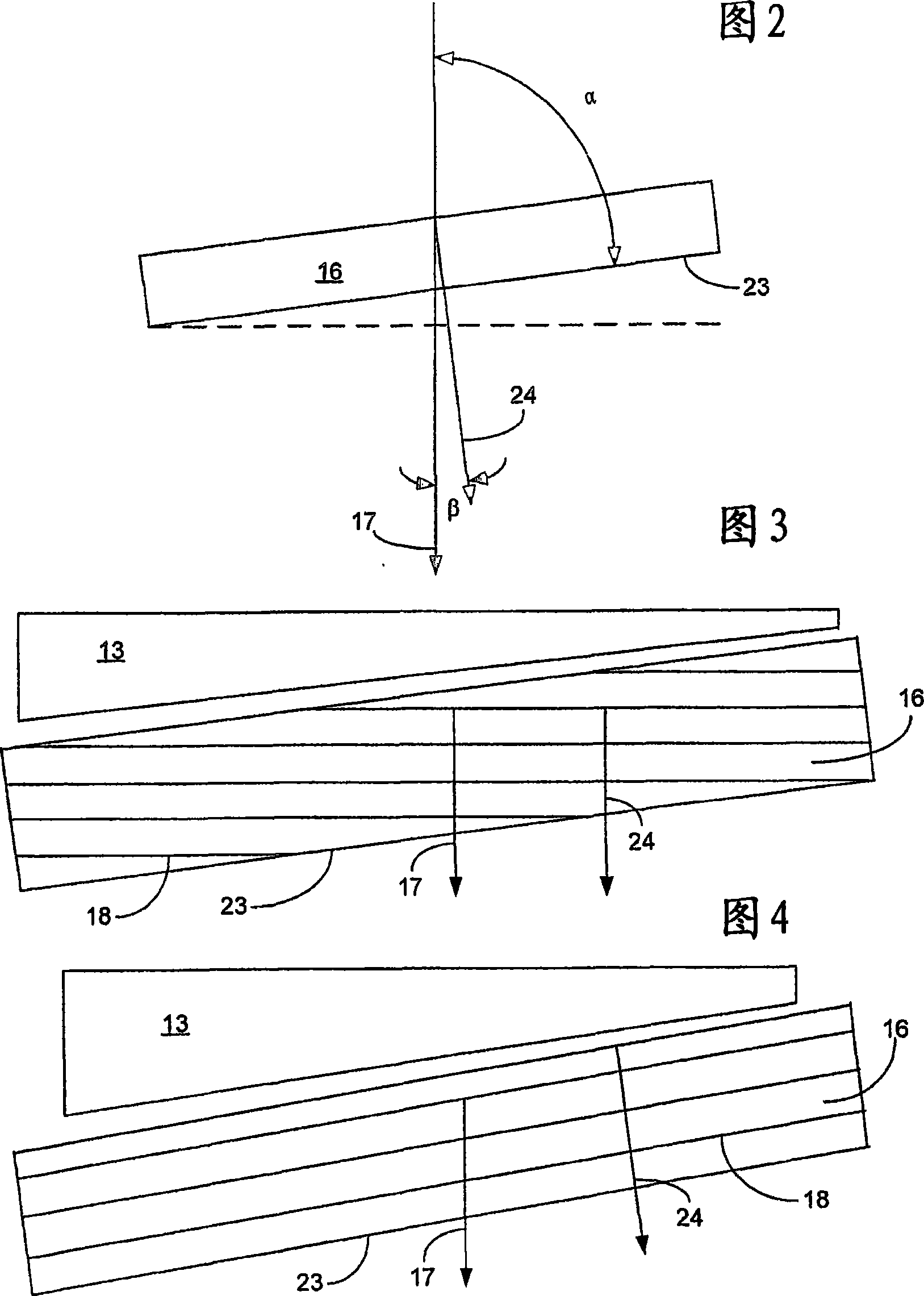

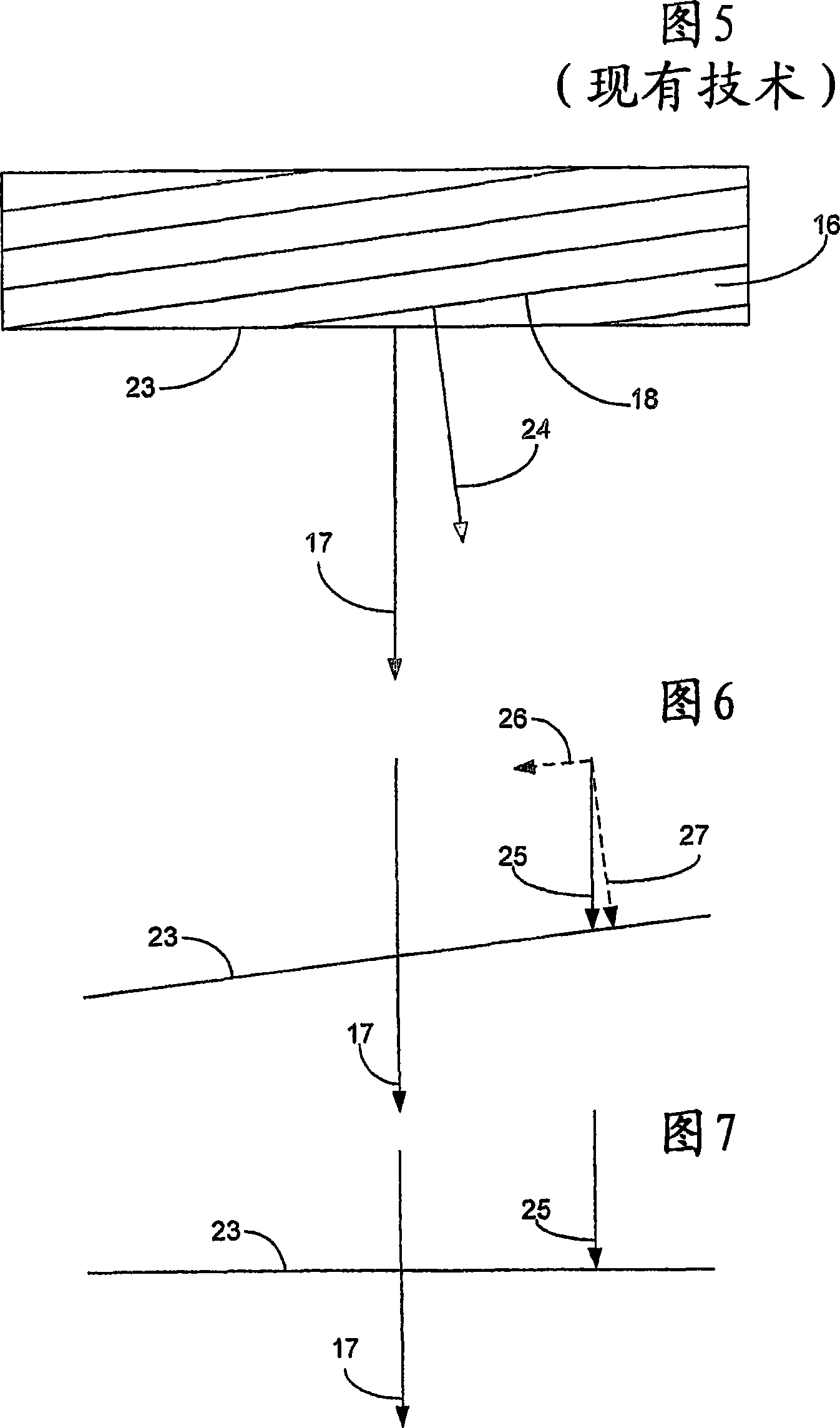

[0027] In a first embodiment, the invention is a seeded sublimation growth system for silicon carbide. In this aspect, the invention includes a crucible, a silicon carbide source composition in the crucible, a seed holder in the crucible, a silicon carbide seed on the seed holder, and means for creating a primary thermal gradient in the crucible , which define the main growth direction between the source composition and the seed to facilitate vapor transport between the source composition and the seed. Place the seed on the seed holder such that the macroscopic growth surface of the seed forms an angle of about 70° to 89.5° with respect to the principal thermal gradient and the principal growth direction, and the crystal orientation of the seed is such that the c-axis of the crystal is aligned with the An angle of about 0° to 2° is formed between the main thermal gradients.

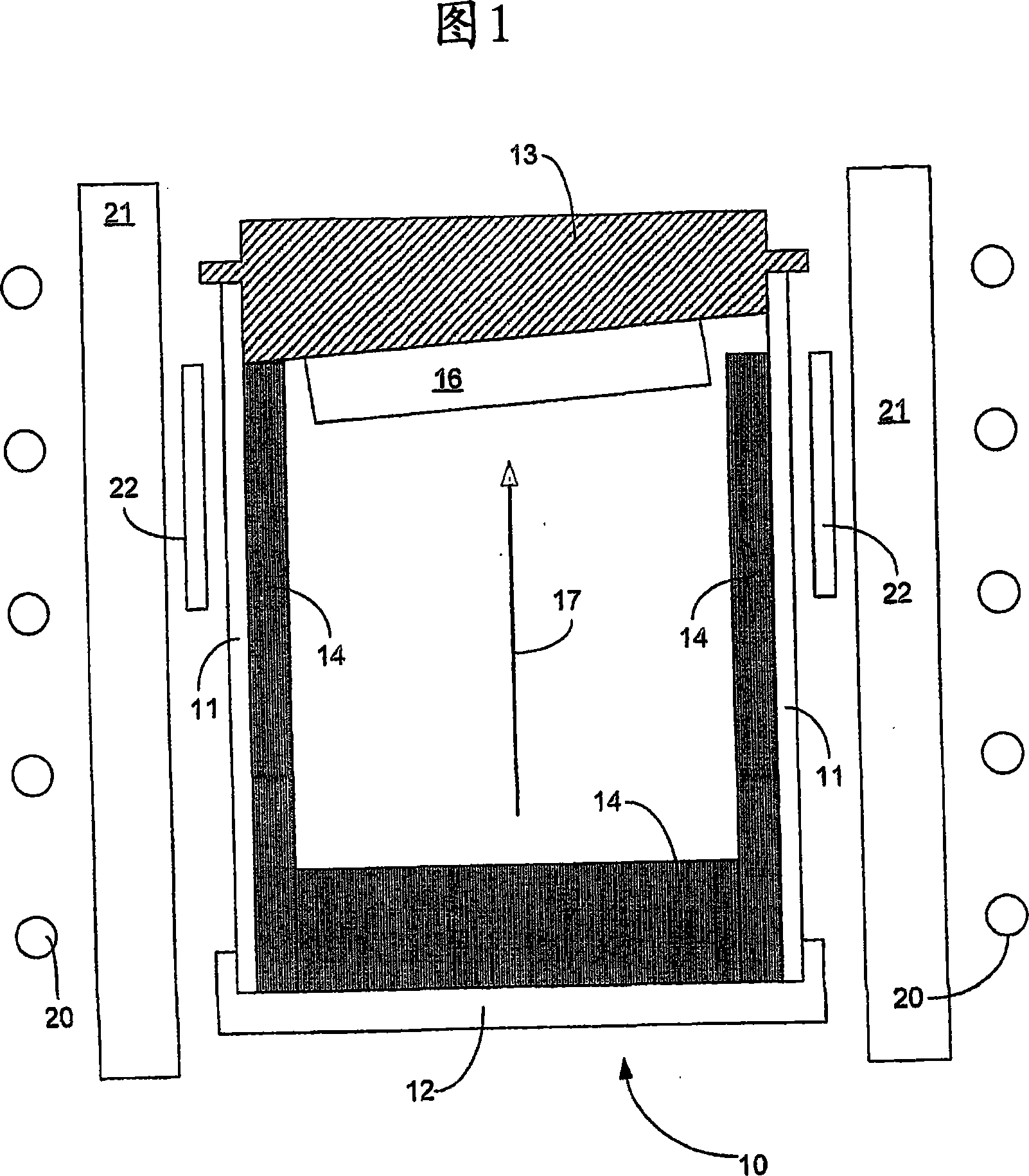

[0028] 1 is a schematic cross-sectional view of a representative seeded silicon carbide sublimation s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com