Process of producing golden granulated sugar or brown sugar by air-float sulfur-free method

A technology of golden granulated sugar and technology, which is applied in sucrose production, sugar production, sugar products, etc. It can solve the problems of high impurity content, low sales volume, and poor storage, and achieve high product quality, low production cost, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

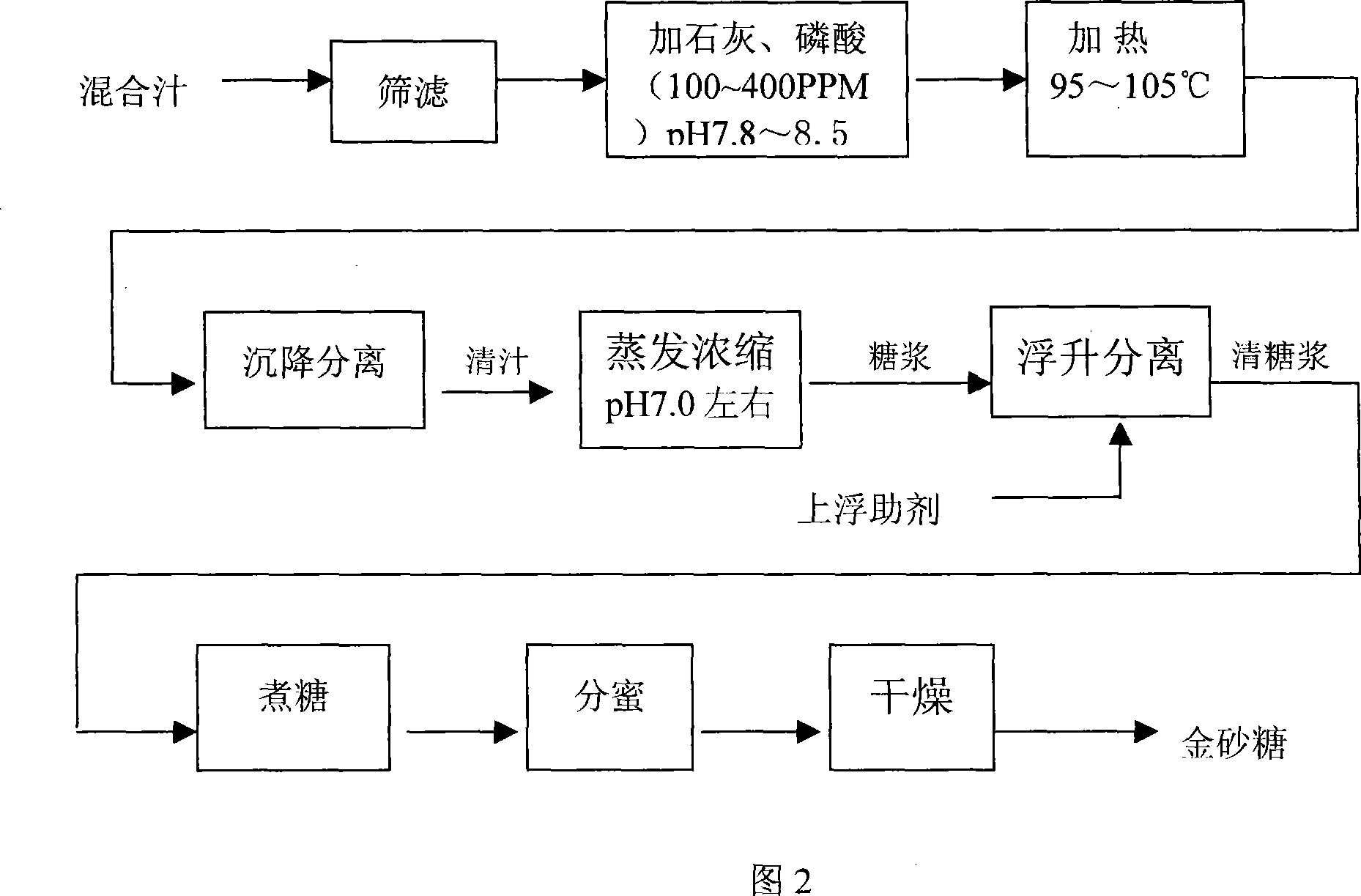

[0020] The production process of golden granulated sugar produced by air flotation sulfur-free method: machine-pressed cane juice (or mixed juice exuded from beets) is used as raw material, and its manufacturing process is shown in Figure 2. The mixed juice obtained from pressing (or oozing) is filtered through a vibrating curved sieve with a pitch of 2 to 3 mm (the pitch of a non-vibrating curved sieve can reach 3 to 4 mm), and then add H 3 PO 4 The total amount is about 400ppm (the sum of the phosphoric acid in the sugarcane itself and the added phosphoric acid), and at the same time, the pH of the ash is adjusted to 8.0-8.5, and the tube heater is heated at 95-105°C, and most of it is obtained by settling in the sedimentation tank. Clear juice, a small part of the mud juice is filtered with a vacuum suction filter or filter press without filter cloth, and the obtained filtered juice is evaporated and concentrated to 60-65°Bx together with the settled clear juice, which is c...

Embodiment 2

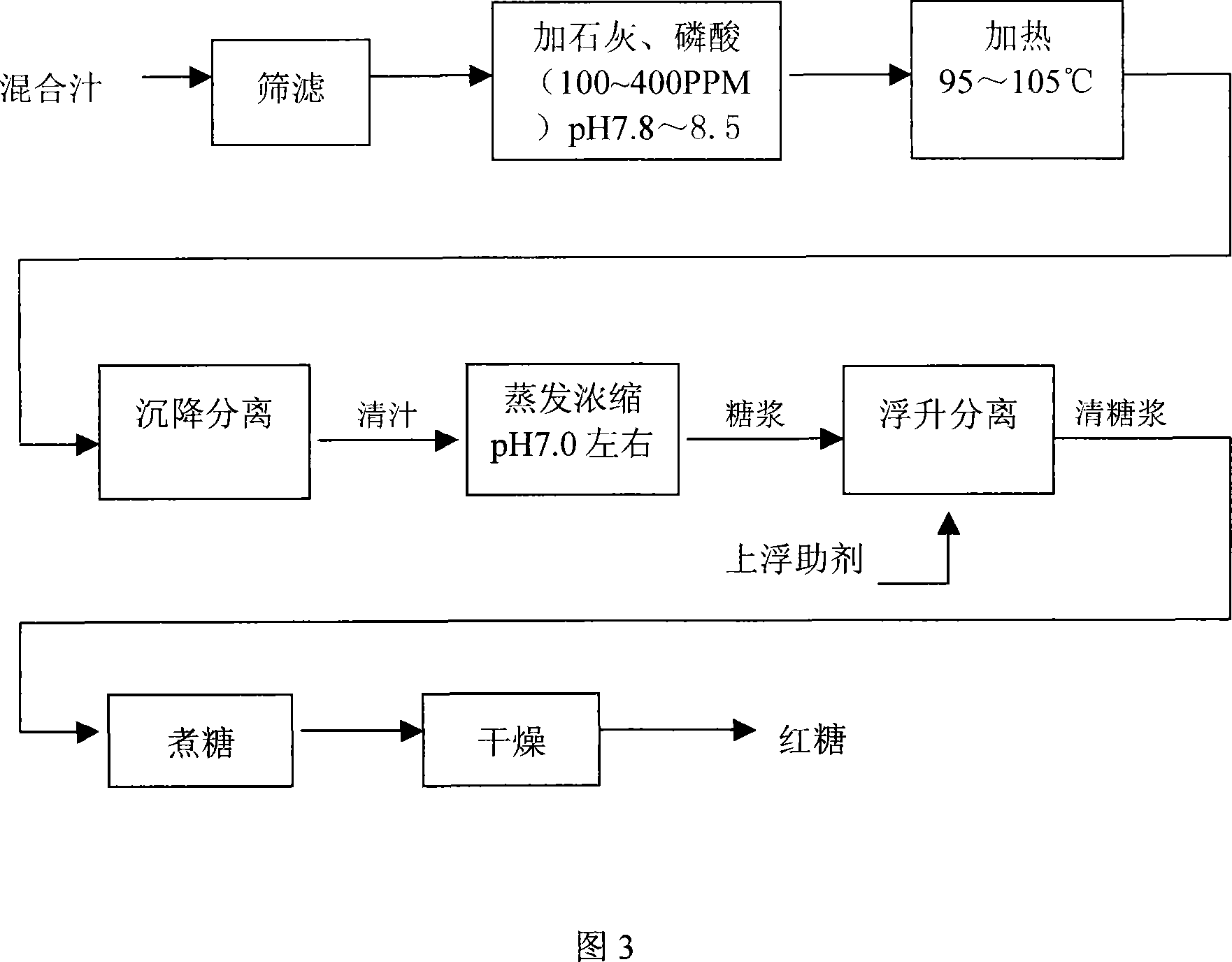

[0032] The production process of brown sugar produced by air flotation sulfur-free method: use machine-pressed sugarcane (or sugar beet oozing mixed juice) as raw material, and its manufacturing process is shown in Figure 3. Each technological index of the cleaning workshop section of this case is the same as embodiment 1. In the lower stage of boiling sugar: when the clear syrup is further concentrated and crystallized, its temperature and concentration are controlled according to the process requirements, and then stirred. When producing brown sugar, the mixture of young sand and mother liquor is formed during the stirring and cooling process to obtain brown sugar; sugar production When powdering, stir, cool down, and grind to get powdered sugar, which can be packaged and shipped after drying.

[0033] Drying process: heat and dry with hot air, or cool and dry naturally.

[0034] Product physical and chemical indicators:

[0035] Appearance: brown sugar is yellow, shiny, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com