Gas layer propulsion electrostatic spinning apparatus and industrial application thereof

A technology of electrospinning and propulsion device, applied in dry spinning, monocomponent polyester rayon, monocomponent polyamide rayon, etc., can solve the problems of environmental pollution, restricting the application of electrospinning method, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

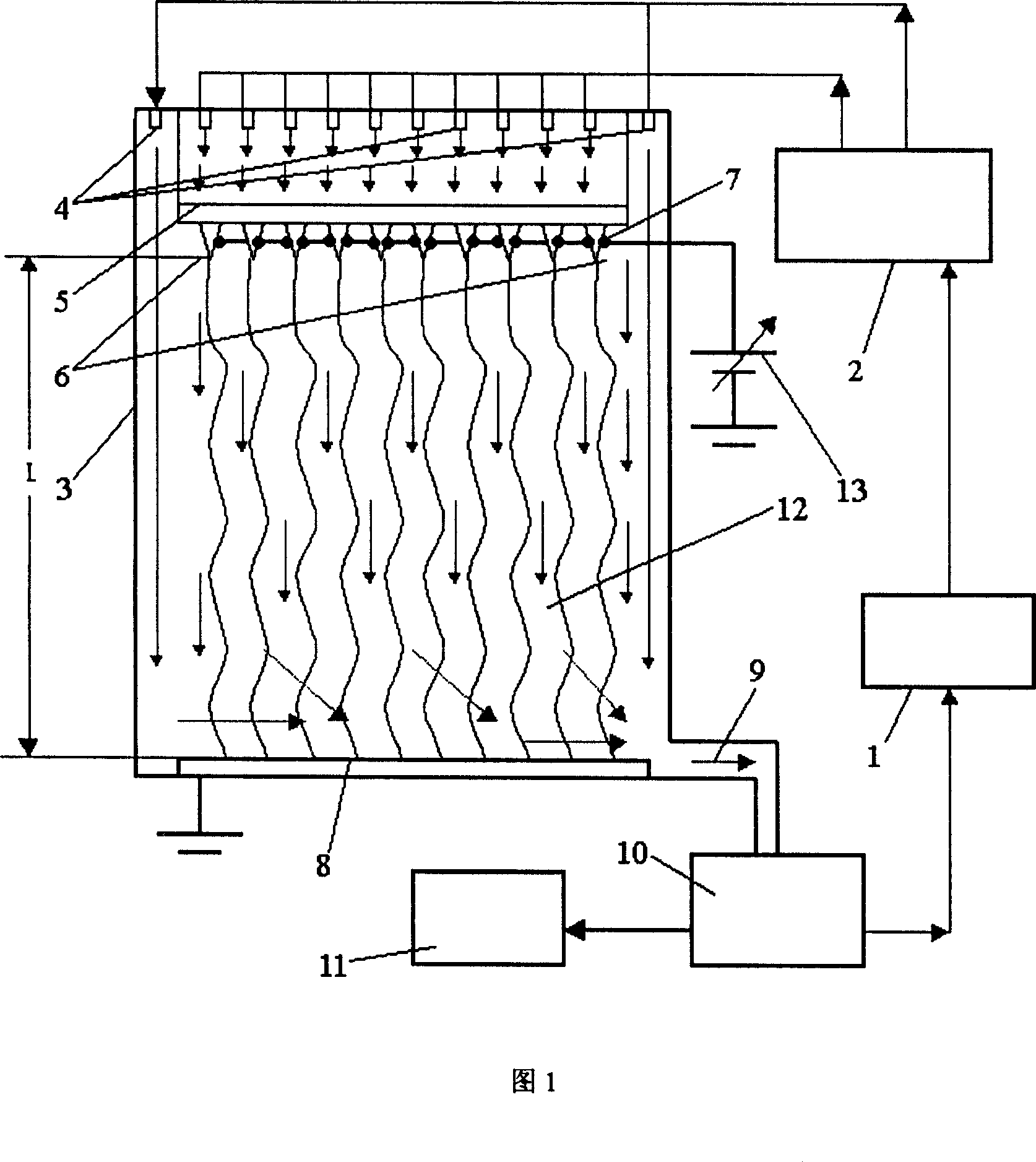

[0035] Spinning was carried out using the apparatus shown in Figure 1. in:

[0036] Said gas circulation propulsion device 1 is a gas compressor, and the spinneret 6 is such as Electrospinning of Nanofibers: Reinventing the Wheel? , Dan Li, Younan Xia, 2004, 16, No.14, 1151-1170, the technology reported in the Advanced Materials literature, the gas drying and heating device 2 is a shell and tube heat exchanger.

[0037] The spinning conditions are: the diameter of the spinneret hole is 1 μm; the height of the airtight chamber is 1 m; the number of spinnerets is 10; the spinning stock solution is ejected from the spinneret at a flow rate of 2ml / h (single hole), and the air temperature is The temperature is 60°C; the applied voltage is 15KV; the gas is air, the pressure is 0.35Mpa; the airflow velocity is 0.5m / s;

[0038] The spinning process is: the weight concentration is 15wt% polym-phenylene isophthalamide and 2wt% CaCl 2 The N, N-dimethylformamide solution is injected in...

Embodiment 2

[0041] Spinning was carried out using the apparatus shown in Figure 1. Wherein: the spinning condition is: the spinneret aperture is 100 μm; the height of the airtight chamber is 1m; the number of spinnerets is 15; the spinning dope is ejected from the spinnerets at a flow rate of 0.15ml / h, and the air temperature is 70°C; the applied voltage is 20KV; the gas is air, the pressure is 0.8Mpa; the airflow velocity is 1.2m / s; the others are the same as in Example 1.

[0042] The spinning process is as follows: the N,N-dimethylacetamide solution of polym-phenylene isophthalamide with a weight concentration of 12wt% and 3wt% LiCl is injected into the material chamber, and the heated and dried airflow is used to push the solution It is uniformly and stably extruded from each spinneret, and the extruded solution forms a thin stream of solution under the action of electrostatic force, and the thin stream of solution moves forward at high speed. The stream finally solidifies into fiber...

Embodiment 3

[0045] Spinning was carried out using the apparatus shown in Figure 1. Wherein: the spinning conditions are: the spinneret hole diameter is 250 μm; the height of the airtight chamber is 0.8m; the number of spinnerets is 10; Out, the pressure is 0.4Mpa, the air temperature is 60°C; the air flow velocity is 0.8m / s; the applied voltage is 12KV; others are the same as in Example 1.

[0046] The spinning process is: the weight concentration is 15wt% polyparabenamide and 2wt% LiCl N,N-dimethylacetamide solution is injected into the material chamber, pushed by heated and dried air flow, and the solution is drawn from each spinneret Uniform and stable extrusion, the extruded solution forms a solution stream under the action of electrostatic force, and the solution stream moves forward at high speed. With the volatilization of the solvent and the drafting of the electrostatic force, the solution stream finally solidifies into fibers. Collected on the material receiving device in the l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com