Combined type biodegradation-absorbing and separating waste gas processing device and the operation method

An adsorption separation and biodegradation technology, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problem that difficult to biodegrade substances are difficult to effectively remove, pollutants cannot be degraded by microorganisms in time, and it is not suitable for dealing with pollution. problems, such as compact structure, small footprint, and reduction of auxiliary equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

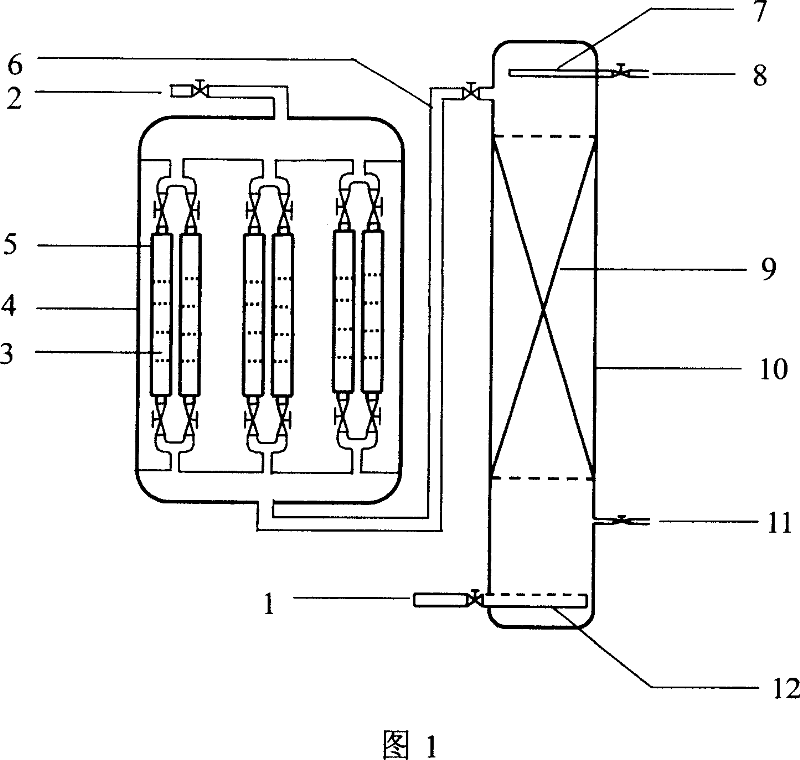

[0040] See Figure 1.

[0041] The combined biodegradation-adsorption separation waste gas treatment equipment made of plastic plates has a length, width and height of 30cm, 15cm and 1200cm respectively, including a bioreactor 10 with a filler 9 and an adsorption separation purifier 4, etc.; A bioreactor 10 with microorganisms and an adsorption separation purifier 4 equipped with an adsorbent 3 are formed;

[0042] An air inlet 1 is opened on the lower side wall of the bioreactor 10, and a perforated pipe 12 is installed at the air inlet 1. The other side wall of the lower part is provided with a water outlet 11, the air inlet 1 should be lower than the water outlet 11, and the upper side wall is provided with a spray liquid inlet 8, and there is another perforated pipe 7 at the inlet 8;

[0043] The interior of the bioreactor 10 is filled with fillers 9 such as sponge, ceramsite, perlite or plastic balls, and the other side wall of the upper part is provided with an air outle...

Embodiment 2

[0051] See Figure 1.

[0052] The combined biodegradation-adsorption separation waste gas treatment equipment made of plastic plates has a length, width and height of 30cm, 15cm and 1200cm respectively, including a bioreactor 10 with fillers and an adsorption separation purifier 4, etc.; A microbial bioreactor 10 and an adsorption separation purifier 4 equipped with an adsorbent 3 are formed;

[0053] An air inlet 1 is opened on the lower side wall of the bioreactor 10, and a perforated pipe 12 is installed at the air inlet 1. The other side wall of the lower part is provided with a water outlet 11, the air inlet 1 should be lower than the water outlet 11, and the upper side wall is provided with a spray liquid inlet 8, and there is another perforated pipe 7 at the inlet 8;

[0054] The interior of the bioreactor 10 is filled with fillers 9 such as sponge, ceramsite, perlite or plastic balls, and the other side wall of the upper part is provided with an air outlet pipe 6, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com