An arc welding method and the special automatic welding machine

An arc welding method and automatic welding machine technology, applied in arc welding equipment, welding equipment, manufacturing tools, etc., can solve the problem that the welding process cannot be effectively controlled in sections, the thermal deformation of the processed parts cannot be controlled, and the processing quality is stable Poor performance and other problems, to achieve the effect of good controllability of thermal deformation, remarkable technical effect, and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

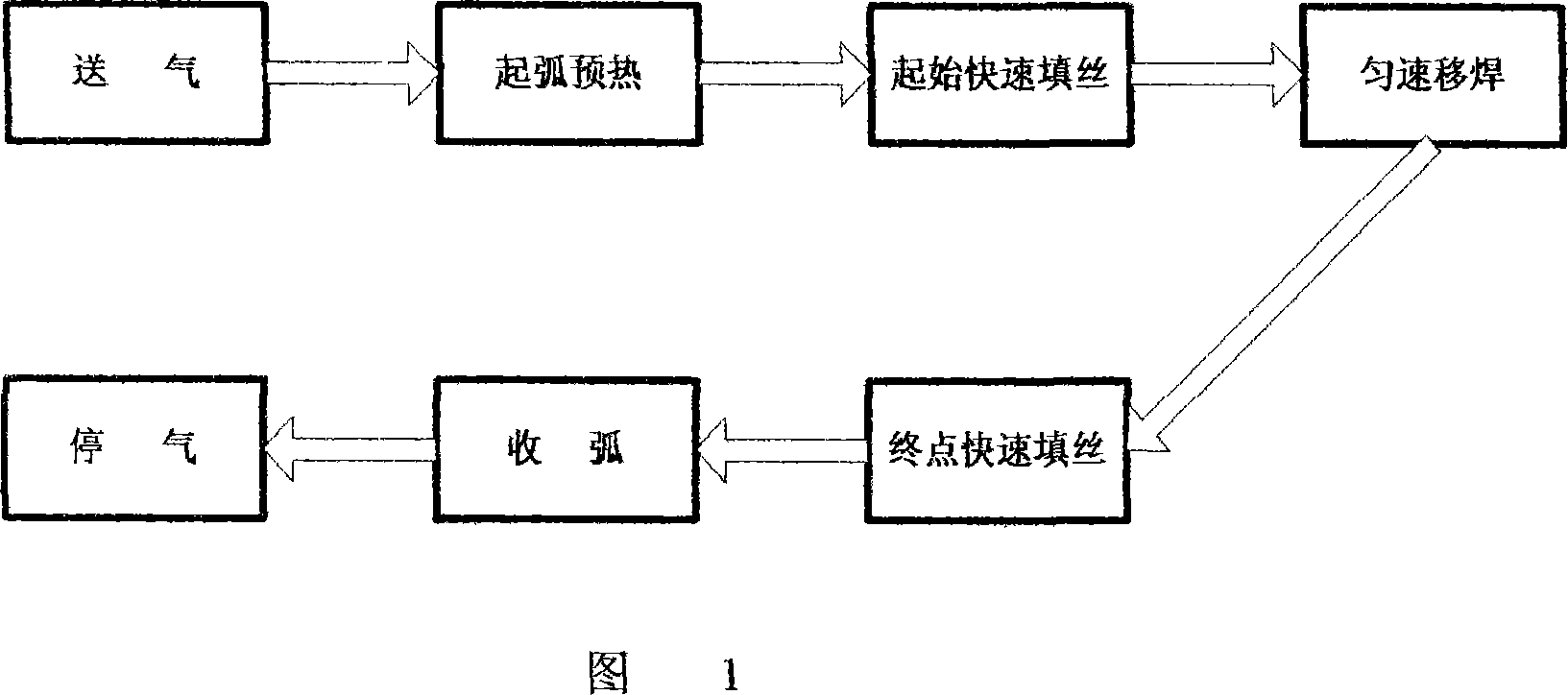

[0041] Described a kind of electric arc welding method, its steps are as follows:

[0042] a. Gas supply: the protective gas to be transported is selected from argon;

[0043] b. Arcing preheating: Preheat the welding joint of the processed part with an electric arc, the preheating time is 0.5 seconds to 1.5 seconds, and this embodiment is 0.8 seconds;

[0044] c. Initial fast wire filling: when the processed parts are not moving, quickly fill the initial welding port with welding wire under the condition of arc heating. The wire filling speed is 5-20 mm / s, and this embodiment is 10 mm / s;

[0045] d. Moving welding at a constant speed: the workpiece to be processed keeps moving at a constant speed relative to the welding wire in the forward direction, and the moving speed is 1 to 8 mm / s, which is 4 mm / s in this embodiment;

[0046] e. Fast wire filling at the end point: when the processed part moves close to the end point of the welding joint, it is quickly filled with weldin...

Embodiment 2

[0049] Embodiment 2. The difference from the above embodiment is that the arc starting preheating time is 1.5 seconds, the initial fast wire filling speed is 20 mm / s, the moving speed of uniform moving welding is 1 mm / s, and the end point is fast The wire filling speed of the wire filling is 5 mm / s.

Embodiment 3

[0050] Embodiment 3. The difference from the above embodiment is that the arc starting preheating time is 0.5 seconds, the wire filling speed of initial fast wire filling is 5 mm / s, the moving speed of uniform moving welding is 8 mm / s, and the end point is fast The wire filling speed of the wire filling is 20 mm / s.

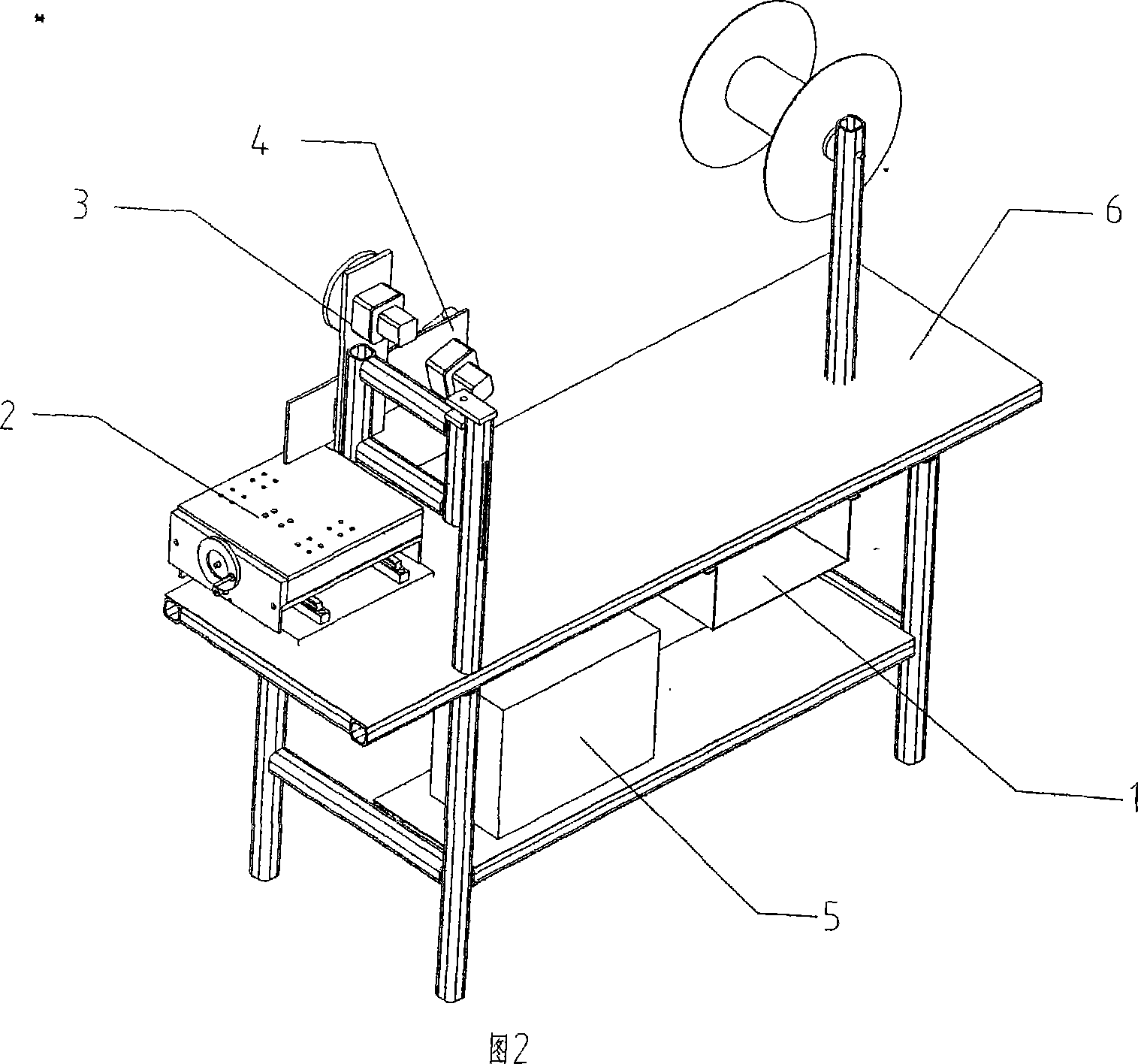

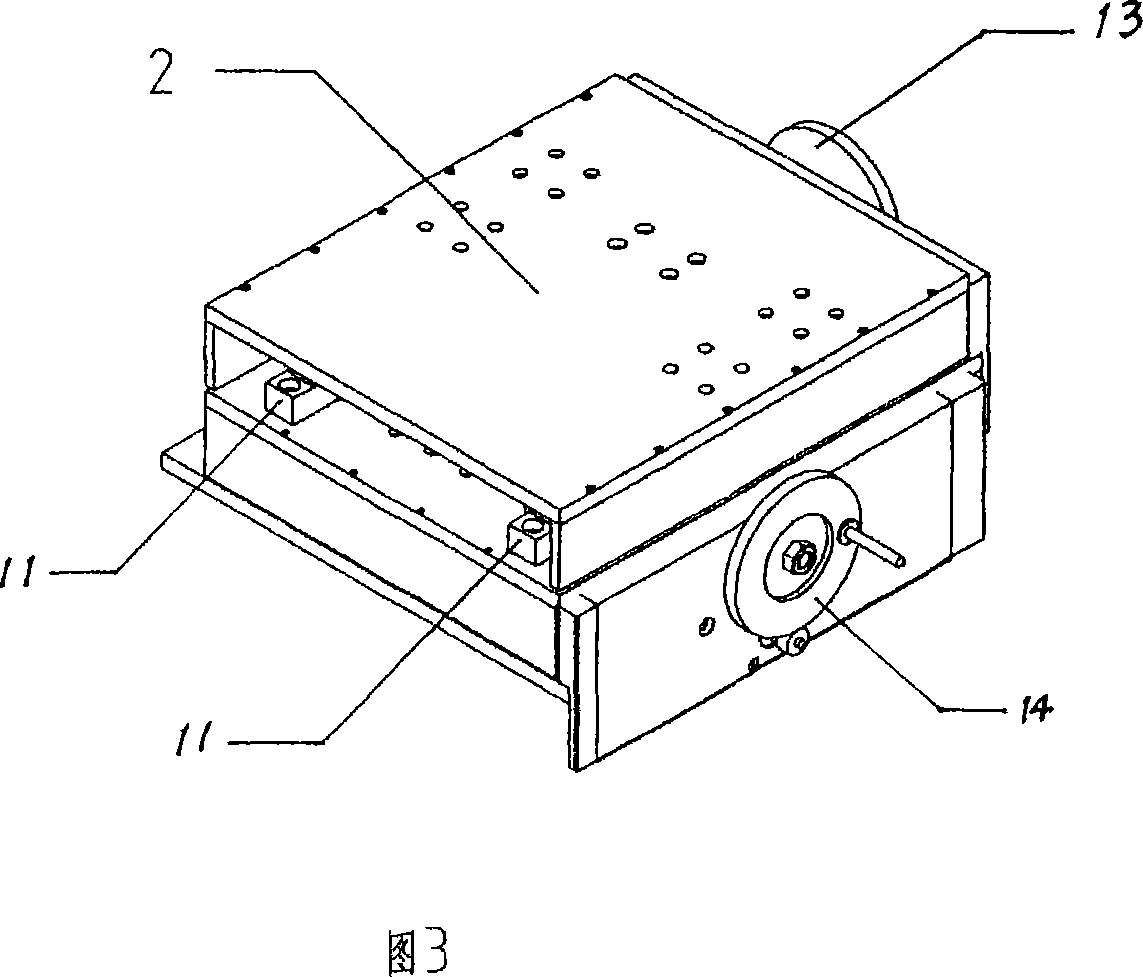

[0051] Two, as shown in Figure 2, 3, 4, 5, 6, be the embodiment of the special-purpose automatic welding machine of implementing aforementioned a kind of arc welding method of the present invention:

[0052]Taking the welding process of BS15 gearbox shift fork as an example, the special automatic welding machine implementing the aforementioned arc welding method has a frame 6, and the components installed on it are: an electric control cabinet 1, the electric control cabinet 1 has A Chinese character display (selected from 128X64 dot matrix with backlight liquid crystal display), a programmable control unit, keyboard input, manual start button, a pedal start switc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com