Improved synthesizing technique for beta-carotene

A technology of carotene and synthesis process, applied in the direction of organic chemistry, etc., can solve the problems of reducing the purity of β-carotene, unsafe industrial production, high production cost, etc., to improve reaction safety, simplify post-processing process, and low production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

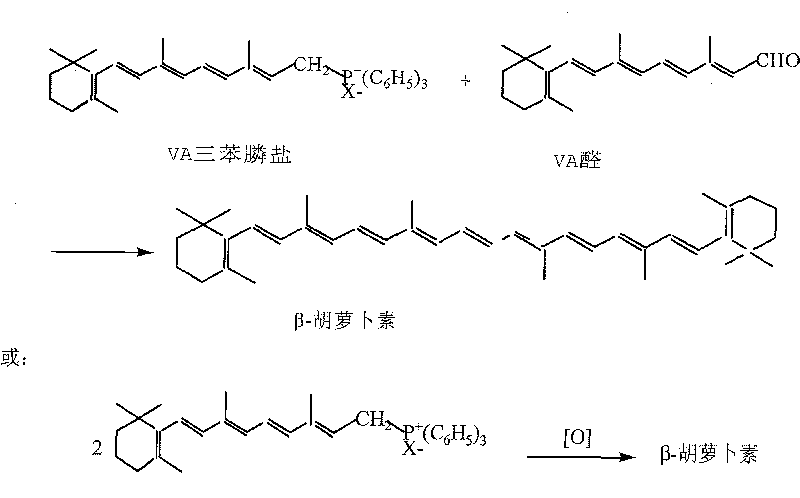

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1: Preparation of vitamin A triphenylphosphine salt

[0019] Put 50 grams of vitamin A acetate (light yellow crystals, 2.8 million IU, 0.147 moles), 39 grams of triphenylphosphine (0.149 moles) and 500 milliliters of methanol in a 1000 milliliter three-necked bottle, cool to 10 ° C in an ice-water bath under stirring, and keep Below 15°C, 15 grams of concentrated sulfuric acid was slowly added dropwise, and the addition was completed in about 1 hour, and then continued to keep warm and stirred for 12 hours, and the reaction liquid turned into an orange transparent liquid. Add 80 g of deionized water, extract twice with 100 ml of n-hexane each time, and the lower layer is methanol-water solution of VA triphenylphosphine salt.

Embodiment 2

[0020] Embodiment 2: Coupling reaction prepares β-carotene

[0021] Put the methanol-water solution of the VA triphenylphosphine salt obtained in Example 1 in a 1000 ml four-neck bottle, cool it to 0° C. in an ice-salt bath, and add dropwise 150 grams of sodium hypochlorite aqueous solution containing 10% available chlorine under 5° C. At the same time, saturated aqueous sodium carbonate solution was added dropwise to ensure that the pH value was between 8-10 after the reaction was completed, and the addition was completed in about 1 hour, and the insulation continued to stir for 1 hour.

[0022] After filtration, 58 grams of red fine powdery crude product β-carotene was obtained, which weighed 50.2 grams after vacuum drying, and the content was detected as 65% by ultraviolet-visible spectrophotometer. The crude product was refluxed in n-heptane for 12 hours under the protection of nitrogen, then cooled, filtered, and dried to obtain 30 g of dark red crystals with a content of...

Embodiment 3

[0023] Embodiment 3: prepare β-carotene with VA crystallization mother liquor

[0024] Be the VA crystallization mother liquor of 1.3 million IU with 110 gram content (liquid chromatography analysis: all-trans VA acetate 42%; 13-cis VA acetate 40%, trans VA alcohol 13%) replace embodiment 1 The vitamin A acetate in, other conditions are the same, the methanol-water solution of VA triphenylphosphine salt is obtained. The coupling reaction was carried out according to the conditions in Example 2 to obtain 28.9 grams of β-carotene fine product with a content of 96.7%, and the total yield was 36.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com