Method for preparing intubatton type stainless steel reverser of ball bearing screw rod pair

A technology of ball screw pair and stainless steel, which is applied in the field of preparing ball screw pair intubation type stainless steel reverser, which can solve the problems that the guide ball tube cannot meet the requirements of the guide tube, the roundness of the turning part is reduced, and the ball passes through. , to achieve the effect of improving working strength and service life, smoothing the tube hole and improving the quality of the tongue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

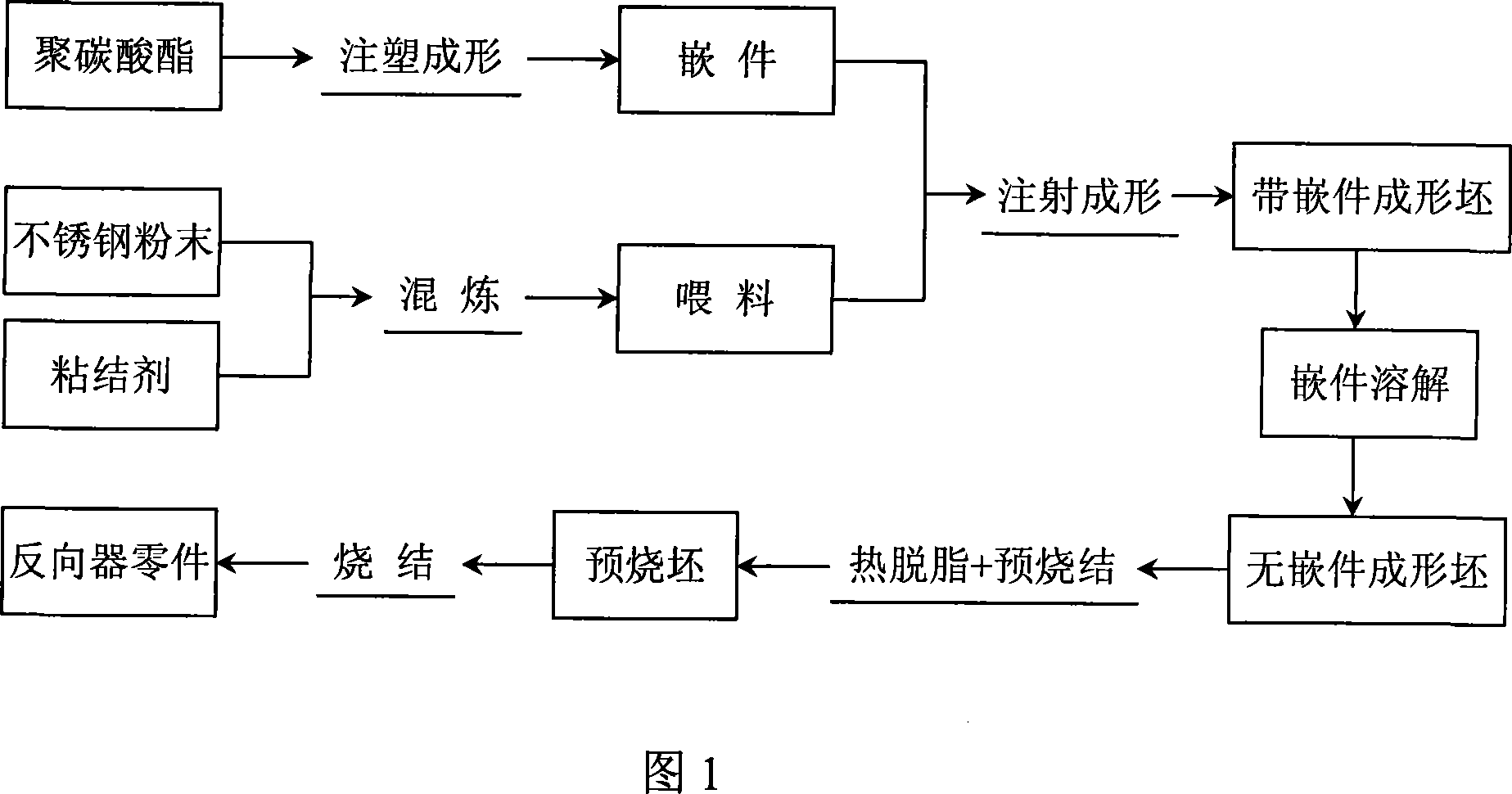

Image

Examples

Embodiment 1

[0020] The average particle size of the stainless steel powder is 4 μm, and the binder adopts a multi-polymer component paraffin-based binder, and the weight percentage of each component is PW:HDPE:EVA:SA=79:13:8:0. The binder was kneaded for 1.5 hours at a temperature of 130° C. on a kneader and then kneaded with stainless steel powder on a kneader at a temperature of 110° C. for 2 hours, and the powder loading was 56% by volume. After granulation, it is injection molded on an injection machine through a bead tube mold equipped with plastic inserts. The injection temperature is 140°C, the injection pressure is 100MPa, and the mold temperature is 30°C. Dissolving and degreasing the plastic insert in a mixed solvent of dichloromethane and trichloroethylene, the temperature of the solution is 40°C. Heat the formed blank of the guide ball tube without inserts in a thermal degreasing furnace under the protection of hydrogen to 200°C for 1 hour, then raise the temperature to 380°C ...

Embodiment 2

[0022] The average particle size of the stainless steel powder is 10 μm, and the binder adopts a multi-polymer component paraffin-based binder, and the weight percentage of each component is PW:HDPE:EVA:SA=70:15:10:5. The binder was kneaded for 1.5 hours at a temperature of 130° C. on a kneader and then kneaded with stainless steel powder on a kneader at a temperature of 110° C. for 2 hours, and the powder loading was 60% by volume. After granulation, it is injection-molded on an injection machine through a bead tube mold equipped with plastic inserts. The injection temperature is 140°C, the injection pressure is 90MPa, and the mold temperature is 30°C. Dissolving and degreasing the plastic insert in a mixed solvent of dichloromethane and trichloroethylene, the temperature of the solution is 40°C. Heat the formed blank of the guide ball tube without inserts in a thermal degreasing furnace under the protection of hydrogen to 200°C for 1 hour, then raise the temperature to 380°C...

Embodiment 3

[0024] The average particle diameter of the stainless steel powder is 10 μm, and the binder adopts a multi-polymer component paraffin-based binder, and the weight percentage of each component is PW:HDPE:EVA:SA=75:15:5:5. The binder was kneaded on a kneader at a temperature of 130° C. for 1.5 hours and then kneaded with stainless steel powder on a kneader at a temperature of 130° C. for 1.5 hours, and the powder loading was 62% by volume. After granulation, it is injection molded on an injection machine through a bead tube mold equipped with plastic inserts. The injection temperature is 140°C, the injection pressure is 100MPa, and the mold temperature is 30°C. Dissolving and degreasing the plastic insert in a mixed solvent of dichloromethane and trichloroethylene, the temperature of the solution is 40°C. Heat the formed blank of the guide ball tube without inserts in a thermal degreasing furnace under the protection of hydrogen to 200°C for 1 hour, then raise the temperature to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com