Gene engineering bacterium of beta - glucosaccharase, and application

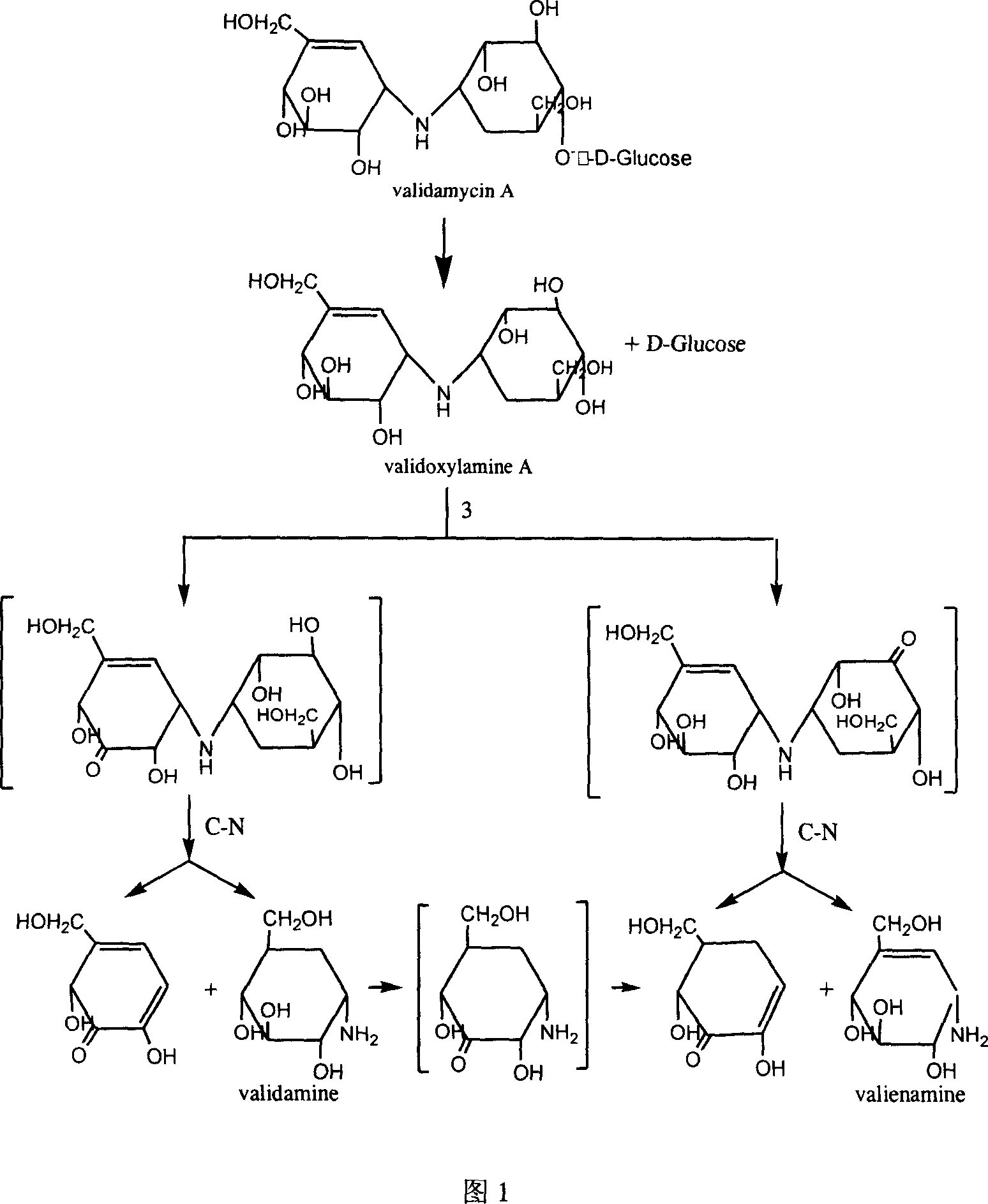

A technology of genetically engineered bacteria and glucosidase, which is applied in the application field of preparing effective mycotoxamine A compounds, can solve the problem of being difficult to prepare and separate effective mycotoxamine A and the like, and achieve the target product effective mycotoxane A. The effect of large amount of base amine A, stable and single product, mild and easily controllable reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Construction of engineering bacteria CGMCC No.1626

[0017] Specific PCR amplification primers were designed and synthesized according to a β-glucosidase gene sequence in the reported complete gene sequence of Agrobacterium tumefaciens str.C58 (GenBank accession no.NC_003063). The 5' ends of the two primers contained a single HindIII. and SacI cleavage site.

[0018] P1: 5'-GC AAGCTT TCACCCCTTCACCACACC-3' (the underlined HindIII restriction site), P2: 5'GCGG GAGCTC ATGGATAGAAAGGCCTCT-3' (SacI restriction site is underlined). Using the genome of Agrobacterium sp.HCCB-20052 as a template, the β-glucosidase gene of primers P1 and P2 was used for PCR amplification. The PCR reaction system was 50 μl, containing 5 ng of Agrobacterium sp. HCCB-20052 total DNA, 25 μl of Premix Taq, and 50 pmol of each primer. Reaction conditions: denaturation at 94 °C for 5 min, followed by 30 cycles of denaturation at 94 °C for 1 min, annealing at 55 °C for 1 min, extension at 72 °C for...

Embodiment 2

[0021] Cultivation of engineered bacteria

[0022] The recombinant engineered bacteria were inoculated into LB medium containing kanamycin (50 μg / ml) and cultured with shaking at 37°C to logarithmic growth phase (OD). 600 to about 0.6), add 1 mM IPTG or lactose, and induce culture at 37°C for 4 hours.

Embodiment 3

[0024] Obtaining of Crude Enzyme and Conversion of Crude Enzyme to Effective Validamycin A

[0025] The induced cultured recombinant bacteria were centrifuged at 4000rpm for 15min at room temperature to collect the bacteria, washed three times with PBS buffer, and then used 1 / 10 volume of 0.05M, pH5.5 citric acid / sodium citrate buffer The bacteria were resuspended, sonicated, and incubated at 4°C with Centrifuge for 25 min and take the supernatant as crude enzyme.

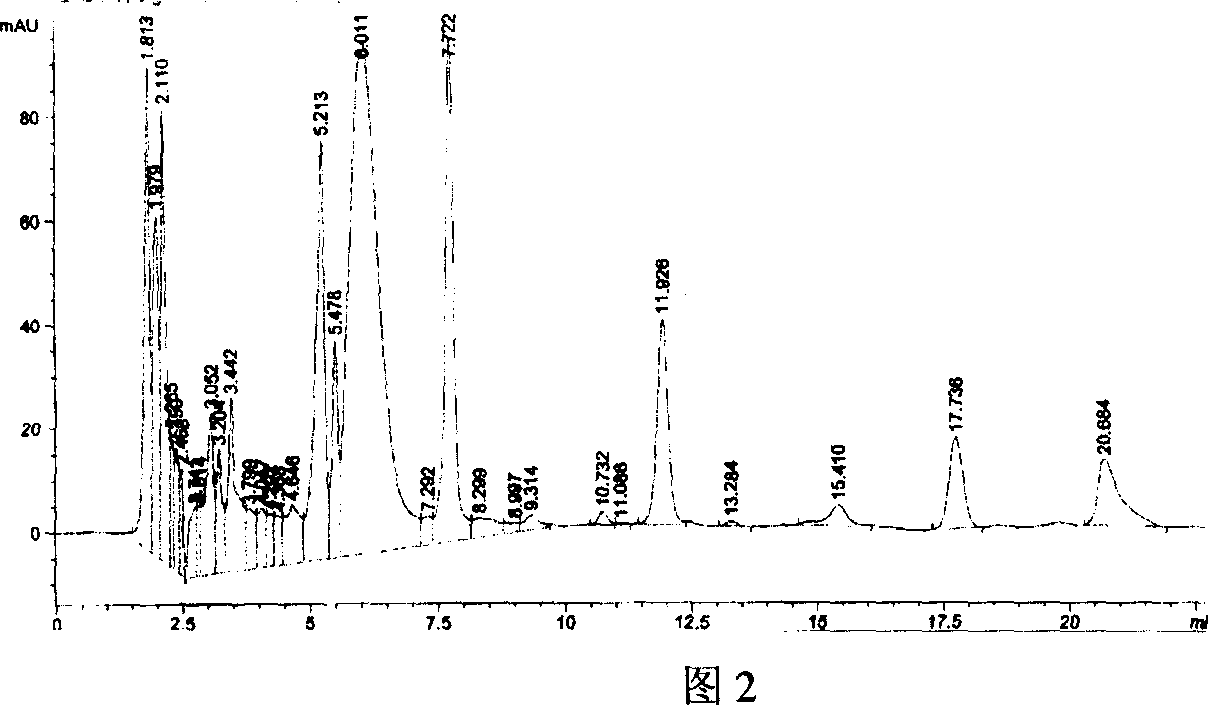

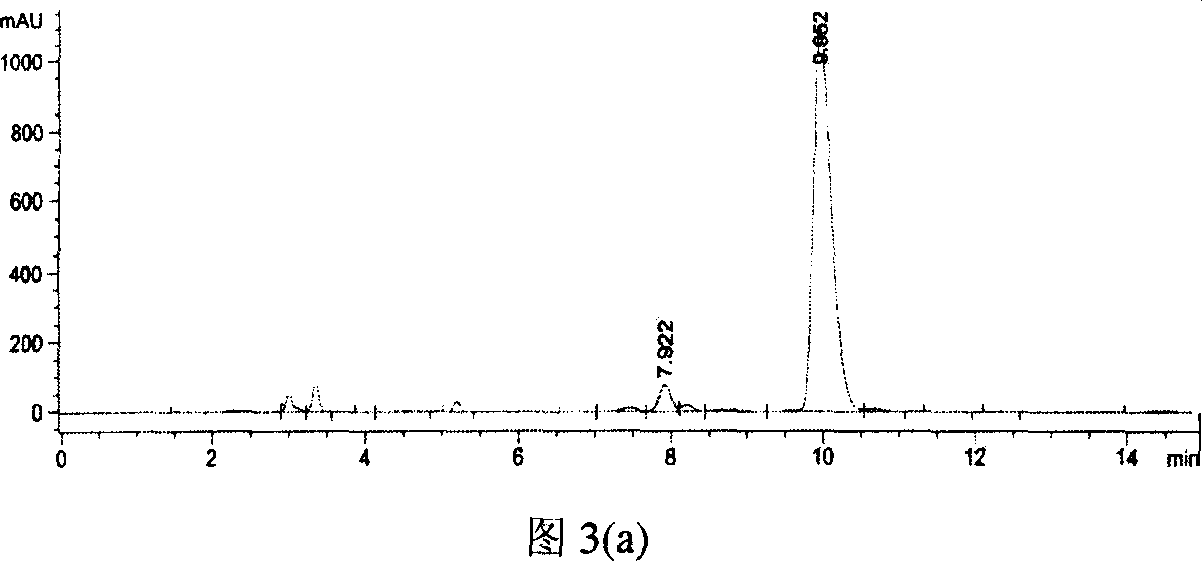

[0026] The crude enzyme solution was diluted 20 times, 20 ml was taken out, 0.1 g of effective valomycin A substrate was added, and the conversion reaction was carried out at 32°C. 54% conversion after 1 hour of conversion

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com