Foaming polyurethanes elastomer, manufacturing method thereof and pallet for railway

A technology of foaming polyurethane, manufacturing method, applied in the field of foaming polyurethane elastomer, to achieve the effects of good compression characteristics, good fatigue resistance, and low water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0113] (1) Preparation of isocyanate-terminated prepolymer (A)

[0114] In a reaction vessel with a capacity of 1000 mL equipped with a stirrer, a cooling pipe, a nitrogen inlet pipe and a thermometer, add 100.0 parts by mass of MDI (containing a mixture of isomers composed of 2,2'-MDI and 2,4'-MDI Diphenylmethane diisocyanate with a content ratio of 1 mass % or less and a 4,4'-MDI content ratio of 99 mass % or more), and poly(oxytetraethylene diisocyanate) with a nominal average functional group number of 2 and a number average molecular weight of 2000 Methyl) polyol 165.9 mass parts, stirred 4 hours at 80 ℃, carried out urethanation reaction, obtained NCO content 10.0 mass %, the isocyanate group terminal prepolymer (A) of average functional group number 2.0 (hereinafter referred to as " prepolymer (A-1)").

[0115] (2) Preparation of polyol mixture

[0116] According to the formulation shown in the following Table 1, 13.64 parts by mass of polyol (B) (the EO-terminated po...

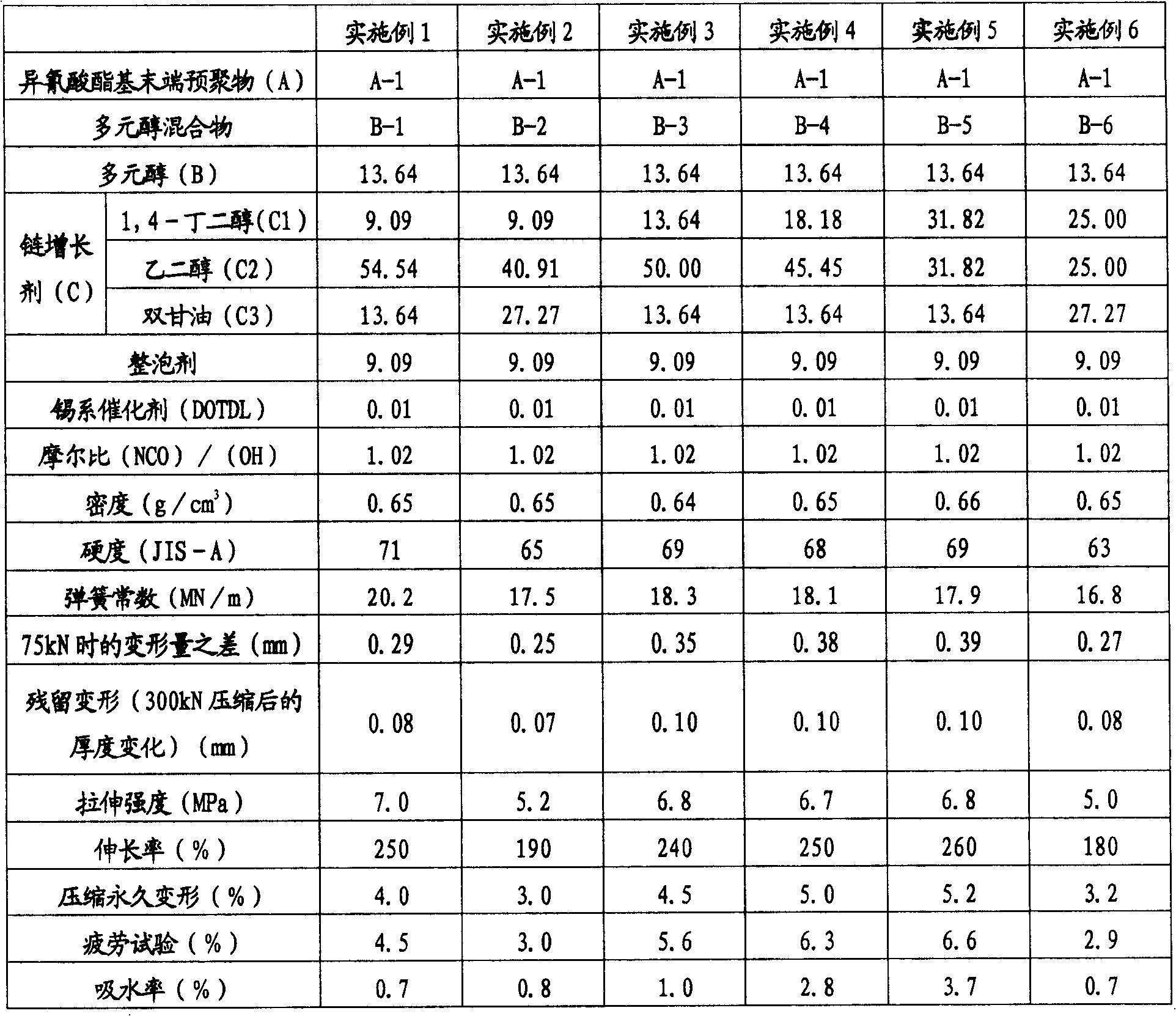

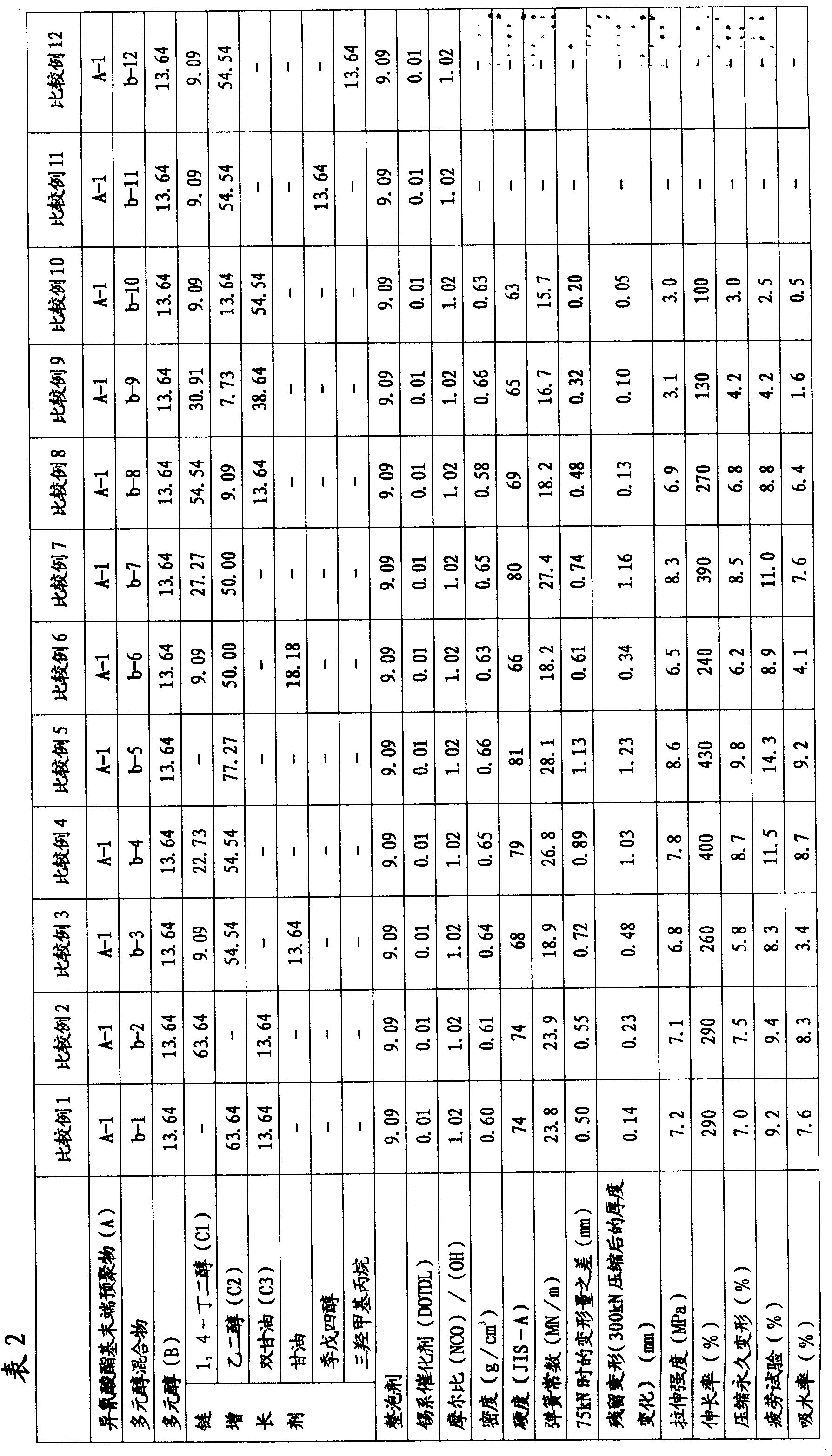

Embodiment 2~6

[0120] According to the formula shown in the following table 1, 13.64 parts by mass of polyol (B), 1,4-butanediol (C1), ethylene glycol (C2), diglycerin (C3), 9.09 parts by mass of foam stabilizer , and 0.01 parts by mass of a tin-based catalyst (DOTDL) were mixed to obtain a polyol mixture. Hereinafter, they are respectively referred to as "polyol mixture (B-2)" to "polyol mixture (B-6)".

[0121] Then, except that the polyol mixture (B-2)-(B-6) was used instead of the polyol mixture (B-1) as the polyol mixture mixed with the prepolymer (A-1), the remaining 1(3) Similarly, the foamed polyurethane elastomer of the present invention (molded product of 140 mm×180 mm×10 mm) was formed and taken out from the mold.

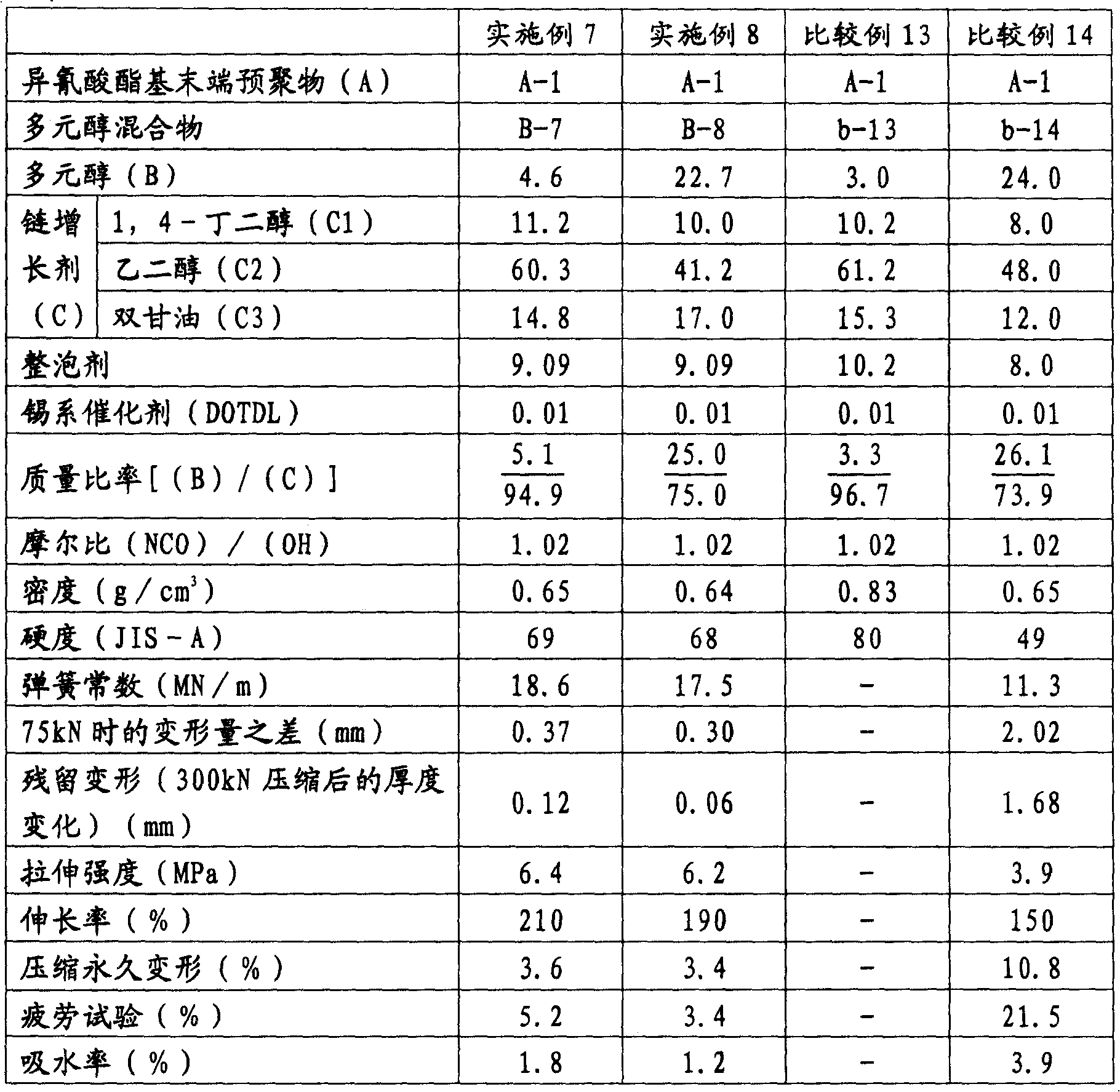

Embodiment 7~8

[0146] According to the formula shown in the following table 3, polyol (B), 1,4-butanediol (C1), ethylene glycol (C2), diglycerin (C3), foam stabilizer, tin catalyst (DOTDL ) are mixed to obtain a polyol mixture. These are hereinafter referred to as "polyol mixture (B-7)" and "polyol mixture (B-8)", respectively.

[0147] Then, except that the polyol mixture (B-7) and (B-8) were used instead of the polyol mixture (B-1) as the polyol mixture mixed with the prepolymer (A-1), the rest were the same as in Example 1(3) Similarly, the foamed polyurethane elastomer of the present invention (molded product of 140 mm×180 mm×10 mm) was formed and taken out from the mold.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com