Powder coal grading clean grading utilization technology using thermal dissociation as the first stage

A technology for pyrolysis and pulverized coal, which is used in the preparation of liquid hydrocarbon mixtures, special forms of dry distillation, and the petroleum industry. , The effect of low operating costs and high economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

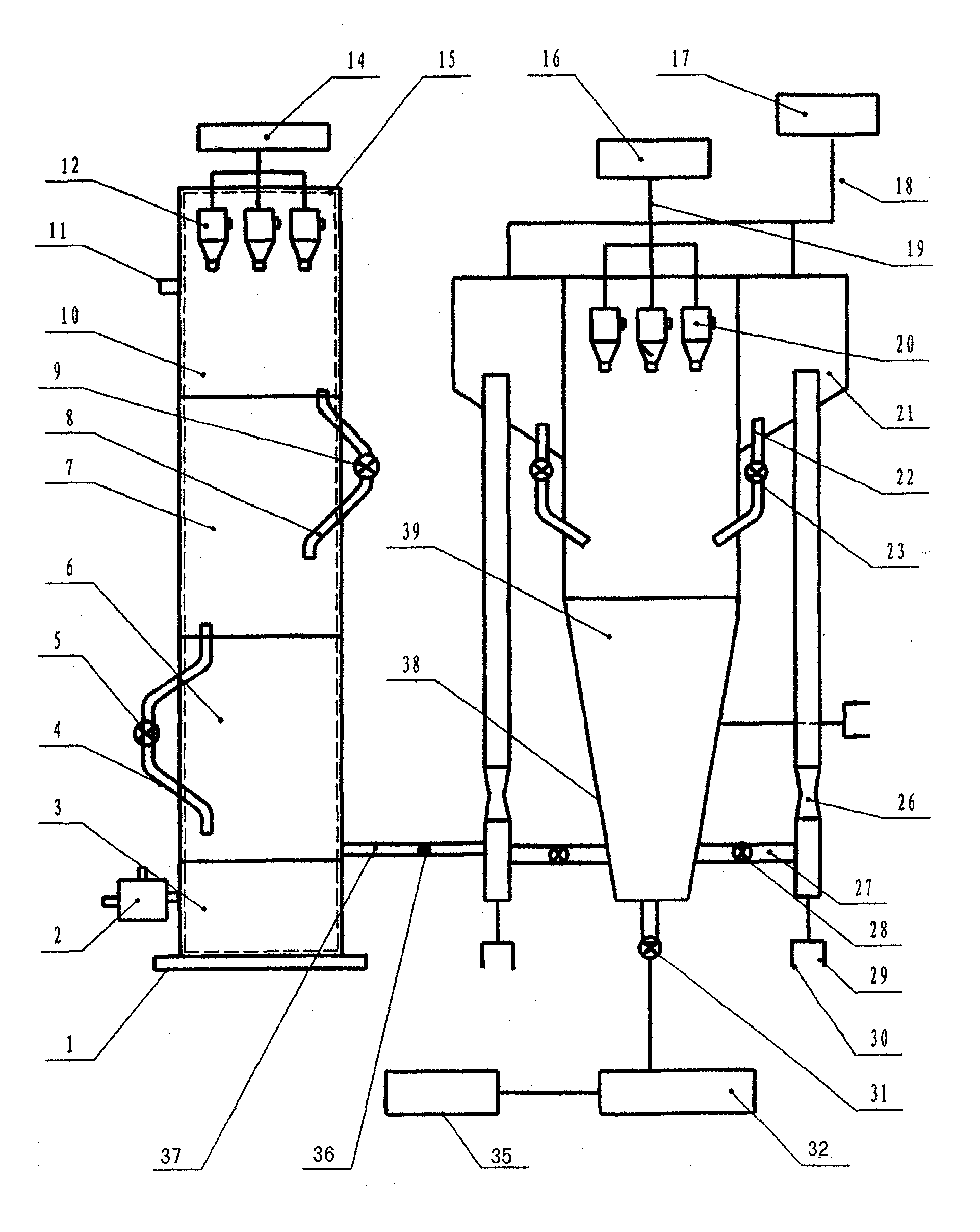

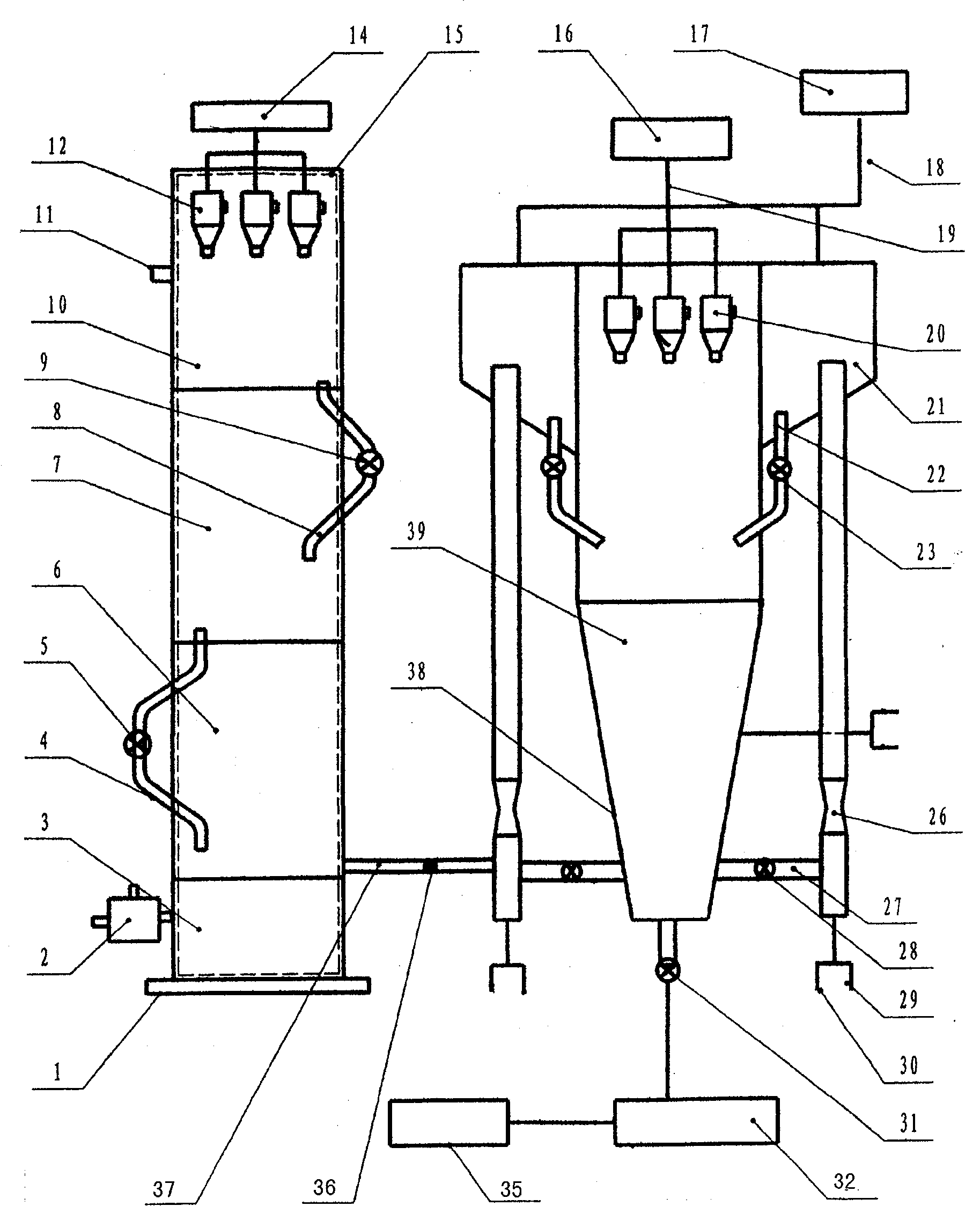

[0008] The present invention is described in detail below in conjunction with accompanying drawing and embodiment, and it comprises: fluidized bed drying pyrolysis device 1, multi-circulation fluidized bed gasification device 38, circulating fluidized bed boiler 32, combined heat and power system 35, it is made of drying Composed of pyrolysis, gasification, and combustion processes, the drying pyrolysis device 1 is composed of a drying bed 10, a low-temperature pyrolysis bed 7, a medium-temperature pyrolysis bed 6, and a combustion chamber 3. After the raw coal is processed and screened by the raw coal processing The pulverized coal enters the drying bed 10 on the upper part of the fluidized bed drying pyrolysis device 1, and after being heated and dried by the coal gas provided by the pyrolysis bed 7 to remove moisture, it is heated to about 150C-200°C and enters the low-temperature pyrolysis bed 7 for heating. Decomposition reaction, pyrolysis humidity

[0009] At about 300°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com