Device for industrialized microwave auxiliary hydrolysed starches and/or fuel alcohol production by cellulose

A microwave-assisted, fuel ethanol technology, applied in enzymology/microbiology devices, biofuels, biochemical cleaning devices, etc., can solve the problems of lack of processes and devices, and achieve the effects of low cost, wide source of raw materials and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

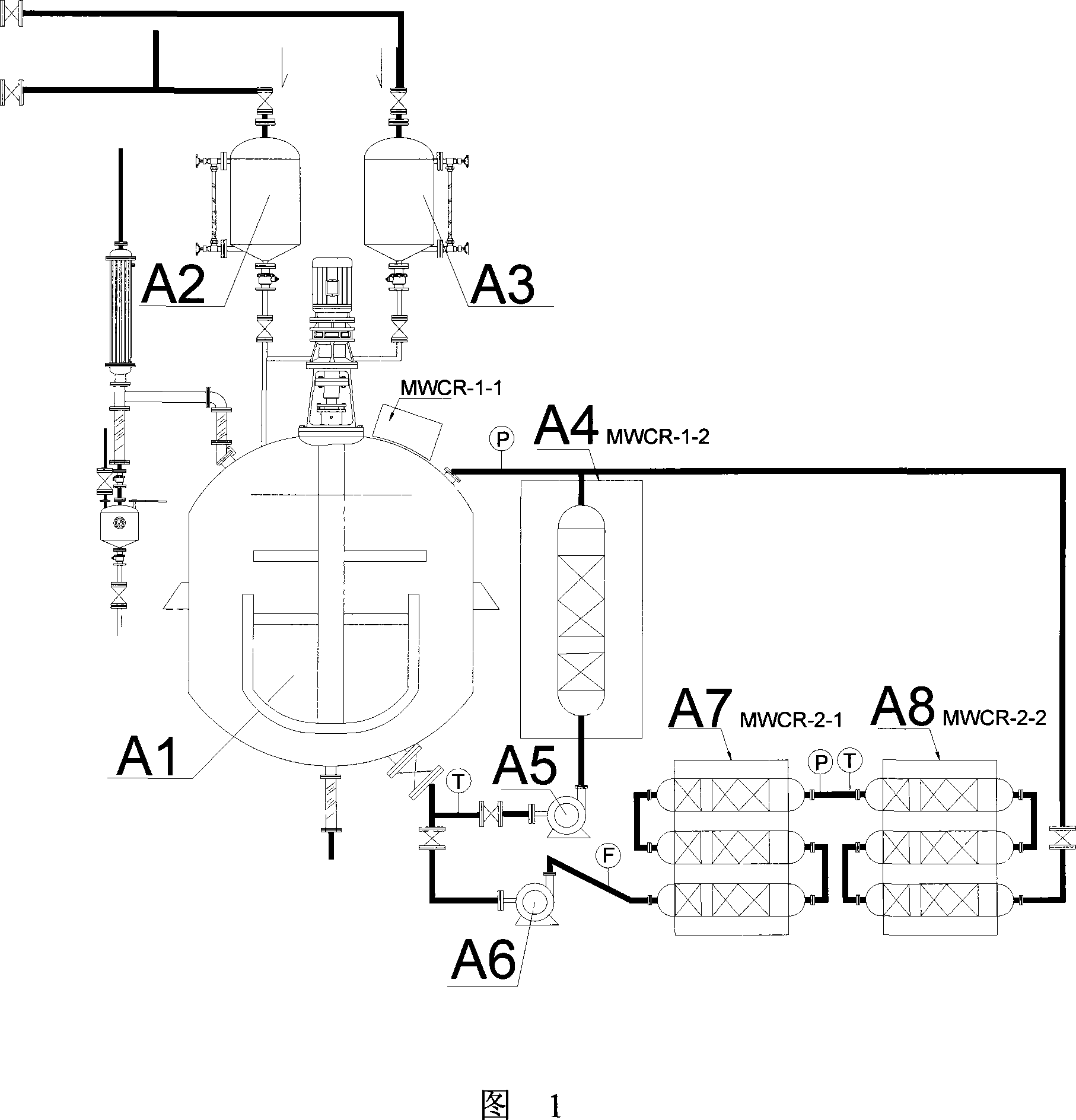

[0069]Example 1: Taking the 5L scale-up test as an example, the raw material of starch and / or cellulose is catering waste. First, solid-liquid separation is carried out on the catering waste, and the food part is left after the solid matter is removed from metal, glass, bamboo, wood, earth and stone, and plastic debris. The food part is crushed and mixed with water at a ratio of 1:3. Put about 2700ml slurry of the crushed and slurried organic waste food into the microwave hydrolysis and saccharification reactor of the process shown in Figure 1 for hydrolysis. Its hydrolyzed slurry composition is as follows: food starch 180g (pure starch), add catalyst dilute hydrochloric acid 900mL and cocatalyst metal halide (such as FeCl 3 ) solution 450mL, add 1500ml pure water to dilute, shake well, the total liquid is about 3000ml. The reactant was hydrolyzed for 6 minutes in the microwave tank reactor shown in Figure 1, and then sent to the second microwave reactor (two microwave tube ...

Embodiment 2

[0072] Example 2: 4M 3 Stainless steel tank reactor scale-up test. at 4M 3 For the stainless steel tank reactor (not connected to the microwave tube reactor in the loop), refer to the catering waste treatment method and the chemical batching method of the above-mentioned embodiment 1, and pre-hydrolyze for 8 minutes. Then it is sent to two secondary microwave reactors connected in series for further hydrolysis reaction for 120 seconds. The yield of glucose was determined to be 97.60% by enzymatic method in literature.

Embodiment 3

[0073] Embodiment 3: The present invention can provide an industrial technical device for the industrialization of the following microwave hydrolyzed starch laboratory research: the frequency of the experimental microwave oven is 2450MHz, and the power is 800w. Add 0.2000g of starch to the reactor, add 2.00mL of dilute hydrochloric acid, and add 1.00mL of 0.15M[X - ] Metal halide solution, shake well and cover to carry out microwave reaction, take out and adjust pH to 7 with NaOH, pour into 25mL volumetric flask with water to volume, pipette 5.00mL into 50mL volumetric flask with water to volume, measure glucose content. The experiment investigated the factors affecting the hydrolysis of starch to glucose, such as the influence of hydrochloric acid concentration on glucose yield, the influence of NaCl on glucose, the influence of various metal chlorides on yield, the influence of other metal halides on yield, and the influence of sulfate on yield. The effects of metal halides ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com