Method for manufacturing stanningmetal plate

A manufacturing method and technology of metal plates, which are applied in the direction of metal material coating process, contour control, pressure inorganic powder coating, etc., can solve the problem of low production efficiency, difficult product quality stability, electrolytic tin plating process and chemical tin plating process, etc. Process adaptability limitations and other issues, to achieve the effect of high tin plating efficiency, low work efficiency, and large equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

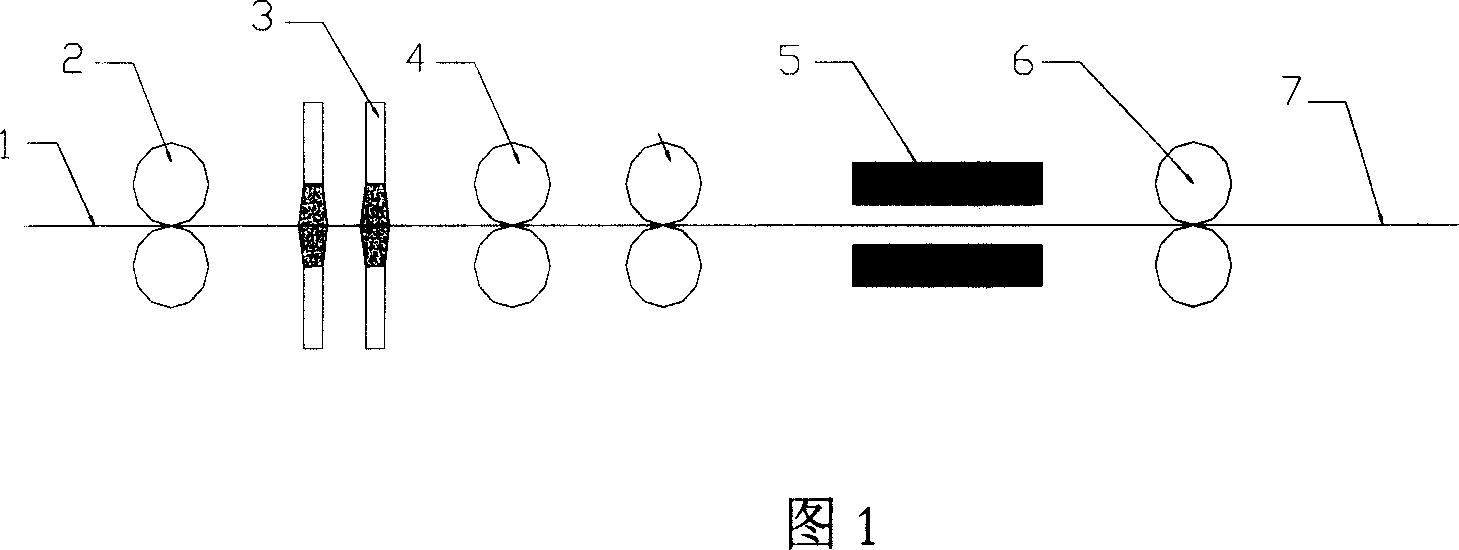

Method used

Image

Examples

Embodiment 1

[0036] The substrate is an IF steel plate with a thickness of 0.25mm. After pickling and drying, the surface is clean and the steel plate is of good quality.

[0037] Use cold air power spraying technology to spray pure tin coating on the surface. The cold spraying process is: the driving gas is a mixture of nitrogen and helium, the pressure is 1.0MPa, the gas temperature is 100°C, and the particle size of the powder is 10-40μm. The thickness is 5 μm.

[0038] After spraying, smoothing treatment is adopted, and the reduction is 1%.

[0039] After reflow treatment at 150°C, a bright tin-plated plate is obtained.

[0040] The test results show that the tin-plated layer is well bonded to the substrate, no iron is exposed on the surface of the tin-plated plate, and the surface of the tin-plated plate is bright.

Embodiment 2

[0042] The substrate is a bronze plate with a thickness of 0.5mm. After the surface is cleaned and dried,

[0043] Use cold air power spraying technology to spray composite tin coating on the surface:

[0044] The first layer of coating: the driving gas is a mixture of nitrogen and helium, the pressure is 3.0MPa, the powder particle size is 1-10μm tin-copper alloy powder, and the temperature is 650°C;

[0045] The second layer of coating: the driving gas is a mixture of nitrogen and argon, the pressure is 1.5MPa, the powder particle size is 40-60μm tin-lead alloy powder, the temperature is 100℃; the total thickness of the coating is 20μm.

[0046] The cold-rolling and finishing-rolling process is as follows: one pass rolling with a reduction of 30%.

[0047] The reflow treatment temperature is 140°C to obtain a bright tin plate.

[0048] The T-bend test shows that there is no crack and peeling of the tin plating layer, and the combination of the plating layer and the bronze ...

Embodiment 3

[0050] The substrate is a zinc alloy plate with a thickness of 1.5mm. After the surface is cleaned and dried,

[0051] Use cold air power spraying technology to spray composite tin coating on the surface:

[0052] The first layer of coating: the driving gas is air, the pressure is 3.0MPa, the powder particle size is 1-20μm tin-cobalt alloy powder, and the temperature is 300°C;

[0053] The second layer of coating: the driving gas is a mixture of nitrogen, argon and hydrogen, the pressure is 1.5MPa, the powder is tin-zinc alloy powder with a particle size of 40-60μm, and the temperature is room temperature; the total thickness of the coating is 30μm.

[0054] The cold rolling and finishing rolling process is: two-pass rolling, and the reduction is 30%.

[0055] The reflow treatment temperature is 150°C to obtain a bright tin plate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com